AOBO Mining Rubber Performance

- Various mining rubbers for different scenarios are available for you to choose from

- High-quality SBR/NR is impact-resistant, wear-resistant, and durable

- Easy to install and maintain, the installation guide

- Super high price and cost-effectiveness, increase your long-term benefits

- Customized needs to meet different equipment specifications

Добыча резины

Когда вы думаете о резине для горнодобывающей промышленности, вы обязательно вспомните компанию AOBO New Material. Резина компании AOBO New Material разработана с учетом различных суровых условий в горнодобывающей промышленности.

Продукция AOBO для резиновой промышленности может предоставить вам большой выбор. Вы можете выбрать из резиновые конвейерные ленты, Конвейерные ленты из ПВХ, резиновые накладки, сэндвич-резина, износостойкий резиновый лист, и резиновый бортик. Все продукты высокого качества, каждый выбор — ваш лучший выбор.

AOBO New Material Manufacturer имеет завод площадью 20 000 квадратных метров и может отправлять горнодобывающую резину напрямую с завода. Мы также пройдем несколько раундов проверки качества перед отправкой. Цель этого — гарантировать, что вы получите самую идеальную горнодобывающую резину. Компания AOBO New Material должна стать вашим лучшим партнером в горнодобывающей резиновой промышленности.

Mining Rubber Protect Various Mining Equipments

Mining rubber includes rubber which used to protect various types of mining equipment, and its uses are very wide. Rubber lining, rubber liner, wear-resistant rubber sheet, sandwich rubber sheet, rubber strip board, etc., are all used for this purpose. Here are some specific application scenarios for you.

Used in vibrating equipment such as vibrating screens and crushers in mines, various rubber sheets can absorb and slow down the vibration generated when the equipment is working, reduce damage to the equipment and foundation, and extend the service life of the equipment.

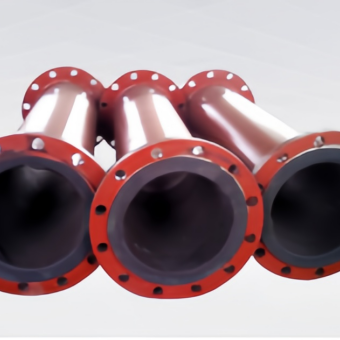

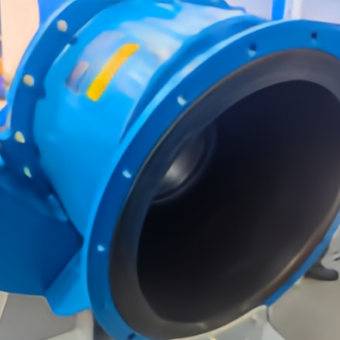

Lining of various equipment such as mills, flotation machines, crushers, cyclones, chutes, silos, slurry pumps, pinch valves, cyclones, slurry pumps, pinch valves, mud pipes, etc..

Casing protection of various equipment such as buffer beds, sweeper scrapers, off-road mine cars, loaders, bulldozers, belt conveyors, etc..

Because rubber sheet material is elastic, has low hardness, is easy to construct, and is wear-resistant, it protects the equipment from damage and increases its service life. Products made of PU materials are highly wear-resistant and highly corrosion-resistant, and are also widely used in mining equipment and conveying equipment to reduce damage to equipment and foundations. PU materials are mostly used for equipment casing protection.

NR natural rubber sheet, equipment lining, protecting the inner wall of the equipment from damage. and thus extend the service life of the pipeline.

Rubber lining can effectively resist the erosion of solid particles in the slurry & chemicals, protect the pipeline from wear and corrosion.

It has excellent flexibility and buffering effect, and reduce the erosion and wear of the inner wall of the pipeline by the material during transportation.

It can buffer the impact of the grinding medium and ore on the cylinder, effectively reducing noise. Also the rubber lining has good wear resistance.

rubber liner- protective effect, in mining equipment, the liner is used to protect the inside of the equipment from the impact and friction of the ore.

wear-resistant rubber sheet or sandwich rubber sheet, installed on the bucket or around the car, fenders, etc., protective effect, protect the vehicle.

To prevent dirt, ore particles and other debris brought up by the tires from splashing onto the vehicle body, surrounding equipment and personnel.

Effectively blocks the dirt and stones brought up by the tracks or tires during the bulldozing process, keeping the working area relatively clean.

AOBO Provides You with a Variety of Mining Rubber

AOBO New Material Company is a strong manufacturer and supplier in the rubber industry. We have a 20-year history in the rubber industry and have accumulated rich industry experience and a profound technical background. The company has a full range of mining rubber product lines. For high-end fields with demanding performance requirements, you can find suitable mining rubber products here. With so many choices, you can make the most correct choice.

Now introduce the mining rubber in detail for you.

Mines mainly include coal mines, metal mines, non-metallic mines, and building materials mines, etc. These mines need many rubber products of various sizes, many varieties, and wide applications, and some have special requirements.

In addition, the mining industry has characteristics such as high load and a harsh environment, so mining rubber needs to be wear-resistant, durable, and impact-resistant. The convenience of installation and maintenance is also very important because the cost of mining equipment downtime is high. Different equipment has different specifications, so meeting your customized needs is the focus of AOBO.

The uses of rubber sheets in mines mainly include the following aspects:

| Roller Lagging | Rubber sheets used for conveyor belt lagging can significantly improve conveying efficiency. For example, diamond wear-resistant rubber sheets adopt an integrated diamond pattern design, which can increase friction, reduce belt slippage, prevent material adhesion, evenly disperse pressure, and extend service life. |

| Conveyor belt | In mines, conveyor belts are used to transport materials such as ore and waste rock. Rubber conveyor belts are the most common type. |

| Rubber linings are used in crushers, various mills, and other equipment | This equipment will be severely worn and corroded during mining operations, especially when handling ores and minerals. Rubber linings can effectively resist wear and corrosion and protect the internal structure of the equipment from damage. The wear resistance of the rubber lining enables it to be used for a long time in a high-intensity working environment. |

| Pipeline linings | In the process of conveying and handling sediment, wear and scaling of the inner wall of the pipeline are very common. Rubber pipe linings can effectively prevent wear and scaling of the inner wall of the pipeline, and can also play a role in shock absorption and sound insulation, improving the service life and production efficiency of the equipment. |

| Ball mill lining | Rubber lining is widely used in ball mills and has the advantages of impact resistance, corrosion resistance, high wear resistance, and low noise. It can effectively reduce the friction and wear of the equipment during operation, extend the service life of the equipment, reduce maintenance costs, and improve the operating efficiency of the equipment. |

| Shock-absorbing rubber sheet | used for shock absorption and noise reduction of mining equipment. It has good impact resistance and requires a certain degree of wear resistance. |

| Rubber seals and sealing strips | used for mine ventilation, drainage, and dust removal systems. Common sealing strips include silicone rubber sealing strips, EPDM sealing strips, chloroprene rubber sealing strips, etc. |

| Vibrating screen sheet | refers to the screen plate used for screening and sorting solid materials such as coal and ore, which is widely used in the coal mining industry. The vibrating screen plate is made of rubber material, has good shock resistance and wear resistance, can effectively reduce the vibration noise of the equipment, and improve the screening efficiency. |

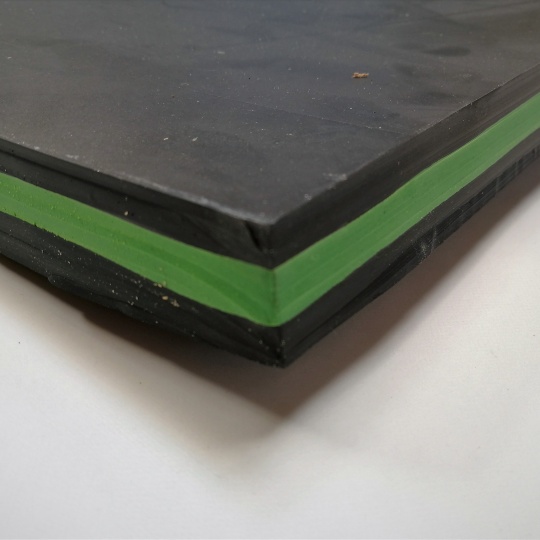

| Equipment protection rubber | Wear-resistant rubber sheets and sandwich sheets, polyurethane plates, etc. The protective effect of mining equipment, its wear-resistant characteristics, can effectively extend the service life of the equipment and reduce the overall maintenance cost. |

| Skirtboard rubber or PU sheet | used for conveyor belt rubber repair strip, anti-overflow skirt lining, wear-resistant rubber layer, and reinforcement layer, can quickly repair the tears and scratches of the conveyor belt to ensure production efficiency. There are also some uses for reducing friction and loss in some machinery and equipment. |

| Rubber hose | transportation of slurry, tailings, and gravel particles. In mining and sand and gravel mining, large-diameter acid and alkali-resistant hoses are used for the transportation of slurry, tailings, and gravel particles. In addition, rubber hoses are used in drainage and hydraulic systems. |

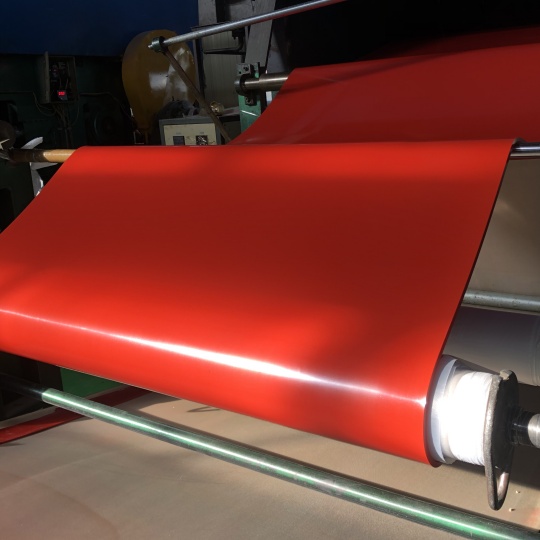

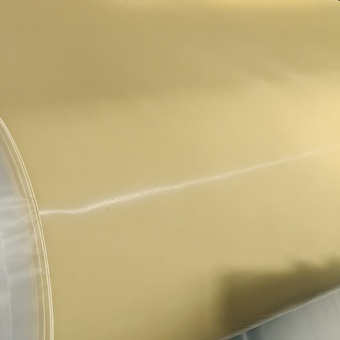

Rubber Lining Sheet Available Colors Can Choose

There are many different colors for you to choose from for natural linings in mines, and they can also be customized according to your requirements.

Usually, the following colors are the most popular: R1038 Red, Tan, Brown, Bright Red, Orange Red…

In some cases, colors can also be used to distinguish different parts or areas for easy installation and maintenance. Rubber linings of different colors have different performances to meet different usage requirements.

Rubber Lining Sheet in Beige

Rubber Lining Sheet in Beige Rubber Lining Sheet in Tan

Rubber Lining Sheet in Tan Rubber Lining Sheet in Brown

Rubber Lining Sheet in Brown Rubber Lining Sheet in Blue

Rubber Lining Sheet in Blue Rubber Lining Sheet in R1038 Red

Rubber Lining Sheet in R1038 Red Rubber Lining Sheet in Orange-Red

Rubber Lining Sheet in Orange-Red Rubber Lining Sheet in Orange-Yellow

Rubber Lining Sheet in Orange-Yellow Rubber Lining Sheet in Bright Red

Rubber Lining Sheet in Bright Red

Your Best Mining Rubber Partner

When you select rubber sheet suppliers for mining equipment, we understand that your decision is far more than the current quotation.

AOBO mining rubber sheet adopts a high-grade wear-resistant formula, which reduces the mining cost per ton while extending the product life by more than 30%, so that the frequency of equipment downtime and replacement is directly linked to your long-term benefits.

As a manufacturer with ISO 9001 and mining safety certification, we are equipped with a 24/7 global response team to escort you from confirming the details of mining rubber to installation guidance. All products have passed RoHS and REACH environmental protection tests, and are delivered on time with guaranteed quality and quantity, helping your mining project to operate stably at all times.

Aobo Интимное и профессиональное обслуживание горнодобывающей резины

Горнодобывающая резина компании AOBO New Material может быть изготовлена по индивидуальному заказу, чтобы предоставить вам широкий ассортимент горнодобывающей резины.

Благодаря нашему обширному опыту работы на рынке наша профессиональная команда и инженеры могут дать вам самые профессиональные советы, выявить потенциальные проблемы и порекомендовать различные параметры производительности в соответствии с вашей конкретной средой использования.

Например, AOBO может производить продукцию с различными характеристиками 6-20 МПа, но AOBO порекомендует конкретную прочность на растяжение, которую следует использовать в соответствии с конкретной средой вашего строительства, чтобы помочь вам сократить ненужные траты средств. AOBO также учитывает размер вашего ролика, чтобы выбирать продукцию разной ширины, чтобы избежать отходов продукции и помочь вам сэкономить средства.

High Quality and Super Wear Resistance of Mining Rubber

Before the final output, the mining rubber of Aobo will undergo multiple washings and multiple extrusions to ensure the absolute high quality and wear-resistance to offer you an ultra-long service life of mining rubber.

Testing methods for wear-resistant products for your reference: usually use the Akron wear tester method and the rotating drum wear tester method. Rubber products for mining equipment protection: usually use 10N to test wear resistance. The working environment of mining equipment is harsh. For example, the protective rubber of the ore crusher must resist the impact and friction of the ore, and the pressure is very high. The 10N test can simulate the actual working conditions of high pressure and high wear.

Combinate with Conveyor Belts and Screens

Most of this functional mining rubber is rubber wear-resistant sheets and sandwich sheets for you to choose from.

1- Conveyor belt buffer bed: The buffer bed composed of rubber wear-resistant sheets can effectively buffer the impact of ore and protect the conveyor belt from being damaged.

2- Conveyor belt edge protection: As a protective strip.

3- Conveyor belt cleaner scraper: Used to remove ore particles and dust adhering to the conveyor belt.

4- Screen protection: Installing rubber wear-resistant plates around the vibrating screen can prevent ore from overflowing from the edge of the screen during screening, and avoid direct collision between the ore and the screen frame.

5- Screen shock-absorbing support: The rubber wear-resistant sheet uses its elasticity and wear resistance to absorb the vibration energy of the vibrating screen, reduce the vibration transmission to the foundation structure, and play a shock-absorbing role.

Резина в горнодобывающей промышленности имеет различные типы. Защитная резина для оборудования может защищать крупногабаритные машины и оборудование в шахтах, транспортировать добытые камни, соль и другие вещи. ПУ и резина просеивают добытые материалы разных размеров, которые вам нужны. Также есть различные футеровки шкивов и конвейерные ленты на ваш выбор.

Да. Горнодобывающая резина изготавливается из различных типов резины, и вы можете выбрать подходящую резину в зависимости от ее коррозионной активности.

Да.Самые основные свойства резины для горнодобывающей промышленности — это износостойкость и прочность. Она может в основном соответствовать основным горнодобывающим работам, а специальные горнодобывающие работы должны соответствовать специальной резине.