AOBO Rubber Lining Performance

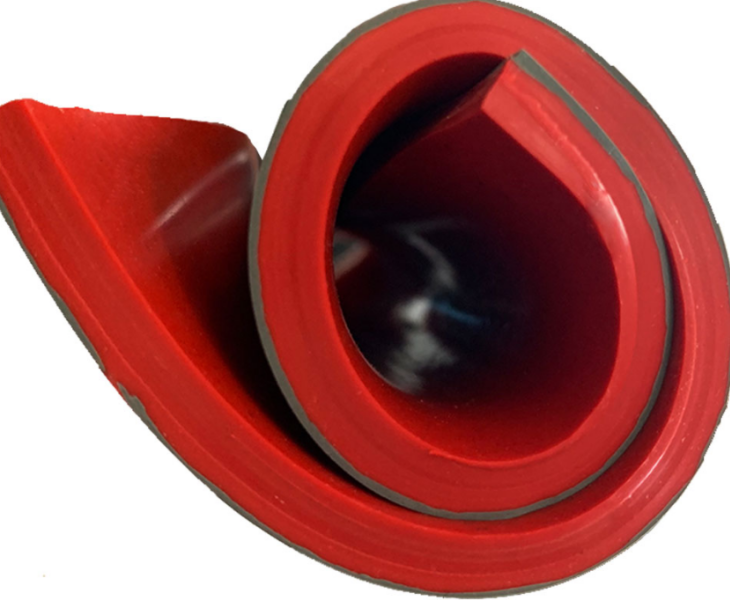

- AOBO has Abrasion-resistant NR rubber lining and IIR Anti-Corrosion Rubber lining, but is used in the mining industry, that is NR Rubber Lining.

- Material composition: 95% natural rubber (NR)

- Popular Types: High wear resistance NR, High tear resistance & high wear resistance & high rebound NR

- High wear resistance, good self-healing, and elongation can reach 800%

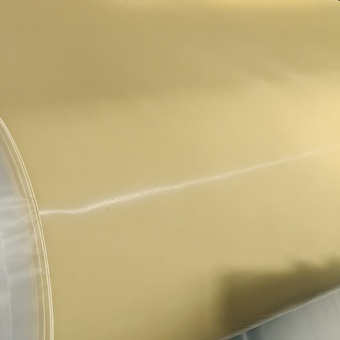

- Color: Red, iron red, tan, brown, black, etc.

- Can be with bonded CN-Layer

7 Types Hot Sell Rubber Lining Specifications

Based on AOBO’s 20 years of global market experience, the high elasticity and long-term wear resistance of natural rubber linings have always been the core needs of industrial customers.

We have selected the 7 types best-selling models for parameter comparison to help you choose the model accurately. Equipped with detailed indicators for your reference, such as tensile strength, wear resistance, specific gravity, hardness, rebound rate, etc.

And support free sample testing and working condition matching analysis.

| Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | Level 6 | Level 7 | |

| Type | Standard | Standard | High Wear-Resistant | High Tensile Strength | High Wear-Resistant | High Tear Resistance, High Wear Resistance | High Rebound NR, High Wear Resistance |

| Tensile Strength: Mpa | 20 Mpa | 22 Mpa | 18 Mpa | 25-26 Mpa | 22 Mpa | 24 Mpa | 24 Mpa |

| Hardness: Shore A | 40±5 | 40±5 | 40±5 | 40±5 | 38±3 | 40±5 | 38±3 |

| Density: g/cm3 | 1.05 | 0.97 | 1.05+-0.05 | 0.97 | 0.97 | 0.97 | 0.97 |

| Elongation | 600% | 700% | 600% | 800% | 800% | 700% | 800% |

| Abrasion-resistant | 120mm³ | 120mm³ | 60mm³ | 80mm³ | 80mm³ | 60mm³ | 90mm³ |

| Resistance (N/mm) | 30N | 30N | 35N | 35N | 40N | 50N | 40N |

| Resilience | 60+-3% | 60+-3% | 65%+-3 | 65%+-3 | 65%+-3 | 65%+-3 | 75%+-5 |

| Natural Rubber% | 60%+-3 | 60%+-3 | 65%+-3 | 70%+-3 | 70%+-3 | 70%+-3 | 95% |

| Working Temperature | -40~+80℃ | ||||||

| Function | This product protects equipment, strips of conveyor belt, Skirts around mining equipment alert personal safety, Anti-overflow skirt | This product protects equipment, strips of conveyor belt, Skirts around mining equipment alert personal safety, Anti-overflow skirt | This product can be used for rubber lining of ordinary equipment with a high wear resistance index. Or for firing range of advanced bullet plates with high wear resistance, long service cycle, and CN layer. Or shockproof to protect equipment. Use as a rubber screen | This product can be used for rubber lining of ordinary equipment with a high wear resistance index. Or for firing range of advanced bullet plates with high wear resistance, long service cycle, and CN layer. Or shockproof to protect equipment. Use as a rubber screen | This product can be used for rubber lining of ordinary equipment with a high wear resistance index. Or for firing range of advanced bullet plates with high wear resistance, long service cycle, and CN layer. Or shockproof to protect equipment. Use as a rubber screen | This product is generally used for pipeline lining or high-end equipment lining, slurry, Ball mill, flotation machine, mud mixing equipment lining, etc., can with CN layer. Or shockproof to protect equipment. | This product is generally used for pipeline lining or high-end equipment lining, slurry, Ball mill, flotation machine, mud mixing equipment lining, etc., and can be used with a CN layer. Or shockproof to protect equipment. |

Rubber lining is essentially a precisely processed rubber sheet or membrane, which aims to provide comprehensive protection for your equipment to prevent erosion or impact damage in corrosive chemical environments. Whether you are facing chemical, mining, transportation or other harsh working conditions, choosing our rubber lining will provide long-term and stable protection for your equipment, helping your production process to be safer and more efficient.

AOBO understands that the rubber market offers a wide range of choices, which can be overwhelming. However, we firmly believe that our rubber lining will capture your attention. Once you fully appreciate the quality and benefits of AOBO company’s rubber linings, we are confident that you will choose our company without hesitation. At that point, we can become each other’s most valuable partners.

Our engineer team have rich experience in rubber industry, can teach you how to construct step by step. All AOBO’s products must be tested layer by layer before they are finally issued and sent.

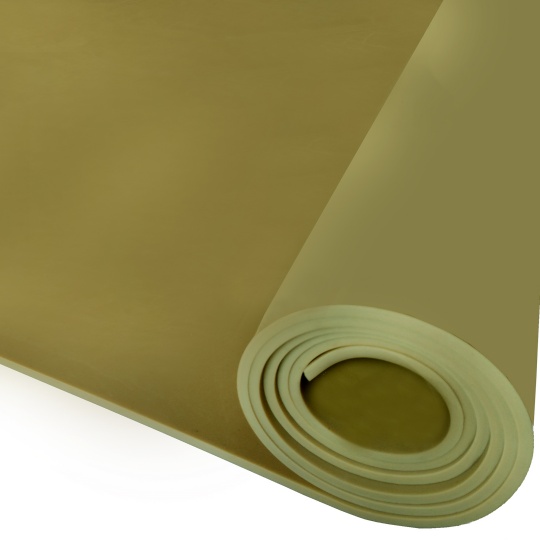

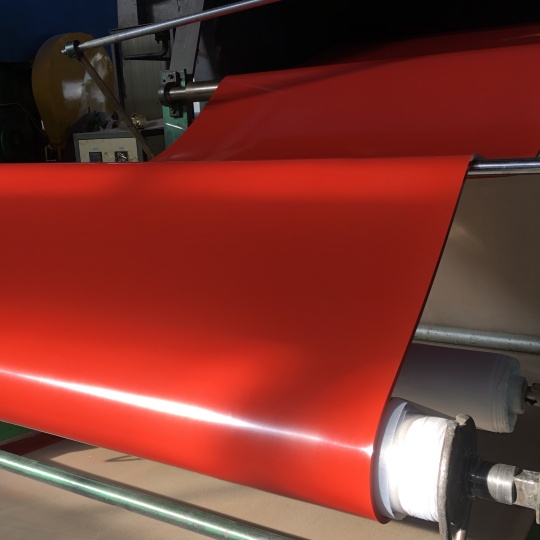

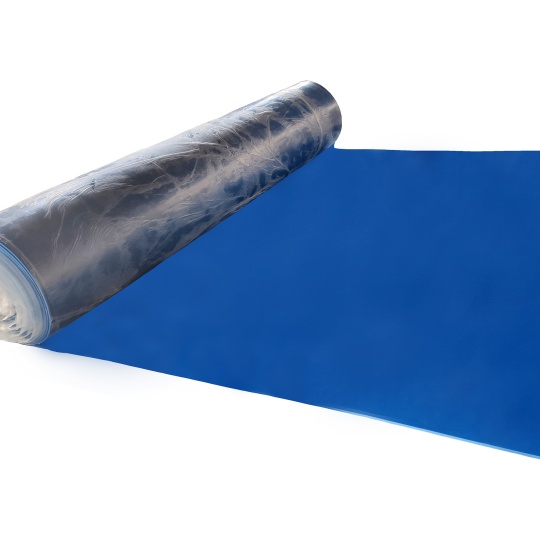

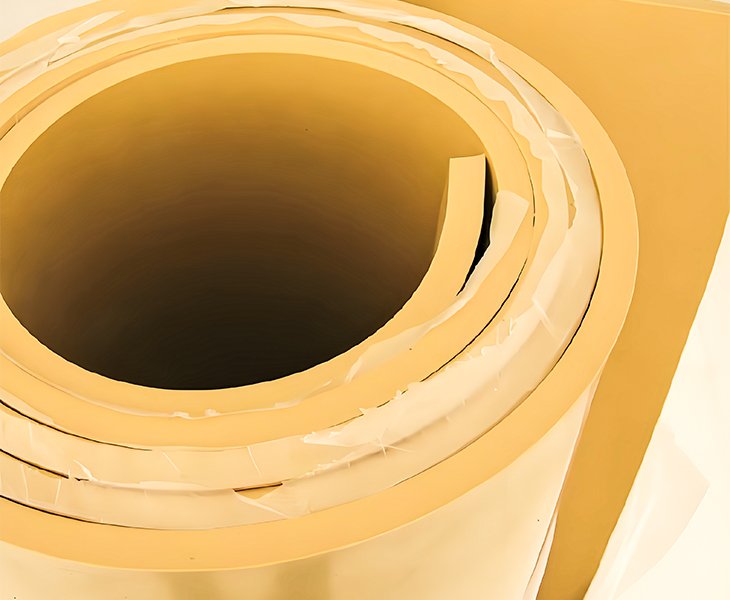

Rubber Lining Sheet Available Colors Can Choose

There are many different colors for you to choose from for natural linings in mines, and they can also be customized according to your requirements.

Usually, the following colors are the most popular: R1038 Red, Tan, Brown, Bright Red, Orange Red…

In some cases, colors can also be used to distinguish different parts or areas for easy installation and maintenance. Rubber linings of different colors have different performances to meet different usage requirements.

AOBO Rubber Lining--Protecting Your Equipment

Is the equipment wearing out too fast in the high-friction mining environment, with alternating dry and wet conditions?

Sharp gravel and foreign matter penetration cause accidental tearing and damage to equipment parts, affecting production safety and continuity?

Impact and vibration affect equipment accuracy, life, or operator comfort?

AOBO Rubber Lining helps you solve all problems.

Abrasion Resistant Rubber Lining

Abrasion Resistant Rubber LiningAOBO rubber lining has extremely high wear resistance, which refers to the performance of rubber lining in resisting surface wear, and can withstand long-term friction and wear.

Full-scenario application (Excellent wet abrasion) Abrasion Resistance at 5N ≤ 100 mm3

For dry abrasion: Abrasion Resistance at 5N ≤ 80 mm3Applicable to both dry and wet mining environments, it greatly reduces your maintenance costs and downtime.

Elastic High Rebound Rubber Lining

Elastic High Rebound Rubber LiningFor rubber lining, the higher the rebound rate, the ability of rubber lining to return to its original shape after being subjected is better, to force the better its elasticity, and the better it can absorb impact.

The high resilience elasticity of AOBO rubber lining up to 75%, indicates that they can recover quickly.

Effectively protect your precision equipment from vibration damage, extend the life of the equipment, while improving the operating environment.

High Tear Resistant Rubber Lining

High Tear Resistant Rubber LiningAOBO rubber lining has high tear resistance, referring to its ability to resist tearing damage, meaning that it can withstand large external tearing and is not easy to be damaged.

AOBO rubber lining can better resist damage when subjected to stress concentration, such as cutting gravel roads, penetrating foreign objects, etc., thereby extending its service life.

Excellent tear resistance up to 60 N/mm, hard to damage, ensuring the safety & continuity of your project.

Rubber Linings Are Extremely Flexible In Their Use

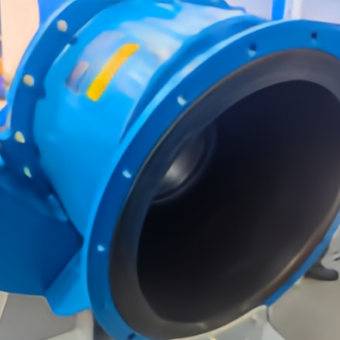

AOBO’s rubber linings are widely used in the chemical, mining, fertilizer production, steel manufacturing, transportation and other industries, especially in the mining industry, to protect your industrial and mining equipment, such as mills, flotation mills, crushers, cyclones, chutes, silos, slurry pumps, pinch valves, slurry pipes, and more.

Typically, rubber linings are used in the following specific applications: ball mill wear linings, flotation machine linings, pipe linings, flue linings, high-end equipment linings, slurry mixing equipment linings, equipment anti-corrosion linings, and other applications such as chute linings, silo linings, and so on.

AOBO utilizes state-of-the-art technology to produce rubber linings in a variety of thicknesses to ensure you achieve optimum performance and durability in a wide range of industrial applications.

Tank rubber lining

Tank rubber liningNR natural rubber sheet, equipment lining, protecting the inner wall of the equipment from damage. and thus extend the service life of the pipeline.

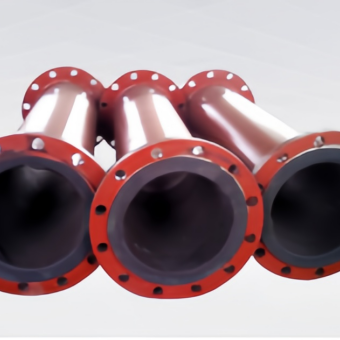

Pipeline lining

Pipeline liningRubber lining can effectively resist the erosion of solid particles in the slurry & chemicals, protect the pipeline from wear and corrosion.

Rubber lining

Rubber liningIt has excellent flexibility and buffering effect, and reduce the erosion and wear of the inner wall of the pipeline by the material during transportation.

Ball mill inner wall

Ball mill inner wallIt can buffer the impact of the grinding medium and ore on the cylinder, effectively reducing noise. Also the rubber lining has good wear resistance.

Rubber Lining Available Size and Size Tolerance

AOBO provides different sizes of rubber lining: covering popular sizes in the market for your reference, or customized sizes according to your requirements.

1/48″, 1/32″, 1/16″, 1/8″, 1/4″, 1/2″, 1″ thickness all available.

| Rubber Lining | Thickness(mm) | Width(m) | Length(m) |

| Popular Size | 6-12mm | 1-2m | 10-20m |

| Available Size | 3-25mm | 0.6-2m | 1-30m |

All rubber lining is strictly implemented: full-size tolerance control following international standards.

If you need special specifications or have any questions, please feel free to contact us for details.

20 years of deep ploughing in rubber industry, specializing in solving the wear and tear problems of equipment under severe working conditions.

Rubber lining, wear-resistant rubber sheet, sandwich rubber sheet, cut strip rubber sheet all kinds of protective rubber.

Comprehensively adapted to your crusher, ball mill, flotation machine, slurry pumps and other 30 + key mining equipment.

Highly elastic rubber absorbs 90% of mechanical impact, guarding the core structure of the equipment.

Abrasion resistance exceeds the industry standard by 40%, resisting the continuous scouring of the ore.

CN-Layer design increases installation efficiency by 50% and reduces downtime.

Shock-absorbing soundproofing technology reduces equipment noise by 15 dB, improving the working environment.

Extend maintenance intervals by 2 times + increase productivity by 35%, reducing operation and maintenance costs.

Unique Advantages Of AOBO Natural Rubber Lining

- Ultra-high wear resistance, good elasticity

- Extraordinary durability, adaptability to extreme environments

- Safety and environmental certification

- Performance and size can be customized according to your needs

- Can be equipped with CN layer

- Good price: With the same quality, our prices are more competitive, giving you an advantage in purchasing

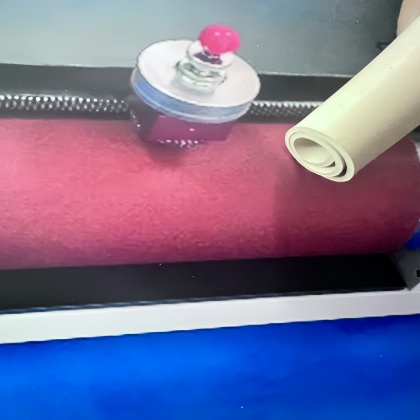

Sandable Rubber Lining - Unbreakable Bond

AOBO’s sandable natural rubber lining is specifically designed to solve the risk of steel plate delamination!

Pre-sanded with a precision belt sander before shipment, the natural rubber lining creates a perfect bonding texture. This results in over 70% increased bond strength, 2 hours of sanding time saved, and reduced glue usage, saving you construction costs.

100% oil-free and dust-free surface – Eliminate delamination risks, no more dust, no need to do on-site sanding, and help you complete your project quickly!

Usage of the CN Layer of the Natural Rubber Lining

The CN layer of the natural wear-resistant rubber lining mainly plays a bonding and protective role.

The CN layer is a special bonding layer that can react with the cold vulcanizing adhesive to vulcanize firmly on the surface, thereby improving the bonding strength and durability between the lining and the tank.

This design makes it unnecessary to grind the CN layer wear-resistant rubber sheet during the bonding process, simplifies the installation process, and improves the stability of the bonding.

And the CN layer can serve as a protective layer to extend the service life of the lining.

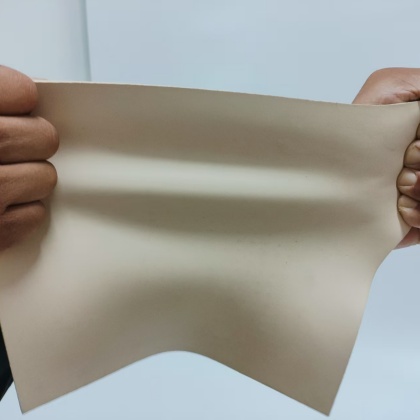

Features of Natural Rubber Lining

High wear resistance: Natural rubber wear-resistant lining has excellent wear resistance, can effectively resist friction and wear, and extend the service life of the equipment.

Good elasticity and flexibility: It can adapt to the vibration and deformation of the equipment during operation, reduce the vibration and noise of the equipment, and improve the operating efficiency of the equipment. And prevent impact and protect the equipment from damage.

Easy to install: Natural rubber lining is light in weight and easy to install, which can effectively reduce the installation time and labor cost of the equipment.

Our rubber lining has excellent resistance to harsh conditions and chemical corrosion, always providing long-lasting reliability.

Supply Different Types Of Rubber Lining For You Choose

AOBO company has two types of rubber linings for you to choose from: Abrasion-resistant NR rubber lining and IIR Anti-Corrosion Rubber lining. And also in different thicknesses, tensile strength, width, length and colors.

The rebound rate of natural rubber linings is very important, and it plays a key role in wear resistance, which can weaken the small and sharp goods you are transporting.

The IIR Anti-Corrosion Rubber linings play a very good preventive role in transporting or storing chemical items in your equipment.

AOBO Rubber Lining Manufacturing Process

AOBO understands that reliable rubber linings are essential for protecting your mining equipment, extending its lifespan, and ensuring optimal operation.

Every step of AOBO’s rigorous process is dedicated to delivering rubber lining solutions that consistently perform, are durable, and provide a perfect fit.

AOBO starts with a selection of raw rubber, and uses precise molding, mixing, and backing processes to ensure even dispersion of the raw rubber and compounds, as well as precise control of the liner’s thickness and flatness.

Each roll of your lining is guaranteed to perform consistently, fundamentally guaranteeing end-use reliability, stability, and long service life, effectively reducing your maintenance costs and risk of downtime, and giving your equipment a longer life. At the same time, it realizes vibration and noise reduction.

AOBO strictly controls the three key elements of the rubber lining vulcanization process – vulcanization time, temperature and pressure – to ensure that the rubber lining is stable, tough, and reliable.

Each roll of your rubber lining has the core performance of high abrasion resistance, high elasticity, anti-aging, etc., providing long-lasting protection for your equipment. Choosing AOBO rubber linings is choosing the peace of mind and efficiency guaranteed by exquisite craftsmanship.

Paper core + Plastic film + Woven bag

Or packaging according to your requirements.

Paper core + Plastic film + Wooden Pallets

Or packaging according to your requirements.

According to the characteristics of natural lining introduced above, we can know that natural lining can protect ore impact, reduce noise and shock, and natural rubber sheet has self-repairing property: slight scratches can automatically rebound and close, reducing crack expansion.

AOBO has Akron abrasion machine and roller Shao Boer abrasion machine to test wear resistance.

Yes.You can communicate with us about the size and specification you want.

If you need technical guidance, our engineers can provide you with installation solutions.

Our prices are definitely competitive in the market, because you not only get the product but also very considerate service. I still think our company’s service can be regarded as top-notch.

Related Hot Sell Rubber Sheets

Butyl Rubber Sheet is also called IIR Rubber Sheet. Good corrosion resistance, best air tightness.

Width 2 cm—80 cm. Different materials are available, with flexible customization.

Diamond pattern, excellent anti-slip and wear resistance, with CN-layer.

High elasticity and wear resistance, made of NR/SBR. 10MPa 15MPa popular.

Natural rubber sheet has best elasticity and high tensile properties/strong tear resistance.