As we know, industrial and mining equipment is the cornerstone for your stable project operation, and these investment costs are high. How can you protect this equipment to avoid wear and corrosion effectively, also to extend the service lifespan? Choosing the right rubber lining is the key to solving this problem, but which material should you use to reach protection effectively?

As a one-stop service rubber lining supplier, AOBO will help you understand the difference between different rubber lining materials, so you can clearly know how to choose.

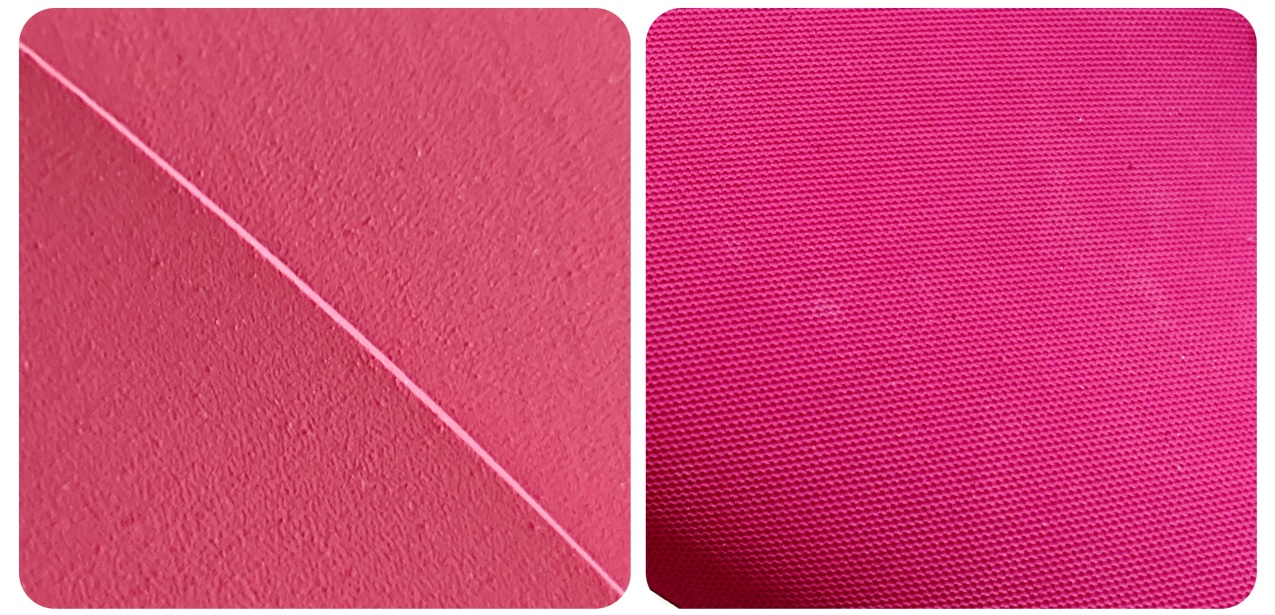

Wear-Resistant Rubber Lining Material–NR Rubber Sheet

NR rubber lining is not only excellent wear-resistant, but also has high tensile strength, high tear resistance, and high rebound. NR rubber is also shockproof, so if your problem is impact and sliding wear, NR Rubber is your best choice.

AOBO NR rubber lining is made with premium 95% natural rubber. This formulation has very good elasticity, tear resistance, and impact resistance. The energy generated by falling rocks and grinding ore is absorbed and dissipated by the natural rubber, protecting the equipment’s metal shell. Also, NR rubber lining can make a different focus according to your detailed application.

Hardness and Physical Properties: 17-29MPa Tensile strength, hardness of 38/40±5 Shore A, always has a sandable surface or fabric impression or CN-layer, which is the most popular and effective grade for most mining applications, offering an ideal balance between flexibility and wear resistance.

Temperature Range: Typically -40°C to +80°C.

Main Applications: Ideal for mining equipment such as: Ball mill and autogenous grinding mill linings, Slurry pipes and chutes, Hopper and hopper linings…

Corrosion-resistant Rubber Lining Material–IIR/Butyl Rubber Sheet

If you use to where need perfectly resistant to chemicals, then butyl rubber (IIR) offers superior protection because of its extremely low permeability and good chemical resistant. The key feature of Butyl rubber is its high resistance to a wide range of acids, bases, and corrosive chemicals. IIR rubber lining sealing is like an impermeable barrier to protect tanks and pipelines from the inside. IIR corrosive-resistant lining can be pre-vulcanized, so it can be installed easily and faster.

Temperature Resistance: Up to 90-100°C in many chemical environments.

Main Applications: Critical to power plants and the chemical processing industry: FGD (flue gas desulfurization) systems, chemical reactors and storage tanks, pickling tanks, wastewater treatment piping and vessels.

Other types of Rubber Lining Material– NBR/CR/HNBR…

According to various application, also below materials can use for rubber lining.

Chloroprene rubber (CR): Excellent weather, ozone, and oil resistance. Suitable for outdoor applications or mild corrosion.

Styrene butadiene rubber (SBR): An economical alternative to NR for less severe abrasion conditions.

NBR & HNBR rubber: Excellent resistance to oil, fuel, and solvents. Ideal for fuel tank linings (NBR) and applications requiring higher temperature and chemical resistance (HNBR).

So, How to Choose?

If you need wear and impact-resistant, especially for mining, we suggest you use NR Rubber Lining.

If you need chemical corrosion-resistant material for use in the chemical industry or a power plant, suggest you choose precured butyl rubber lining.

If you need oil and solvent-resistant, suggest you choose NBR/HNBR.

If you want economical and light wear-resistant, SBR can fit your requirement.

AOBO is not only a rubber lining manufacturer, but also your technical partner. We offer a full range of different materials to meet your various needs. Contact AOBO now to help you analyze and recommend the most suitable rubber lining for maximum equipment life and return on investment.