AOBO Ceramic Pulley Lagging Performance

- Provides standard and flame-retardant ceramic lagging

- CN layer can be directly bonded without grinding

- Strong bonding to avoid debonding

- Increases surface friction coefficient to effectively prevent belt slippage

- Uses wear-resistant ceramic blocks, which have the best wear resistance and extremely long service life

- Suitable for belt conveyor roller lagging in harsh environments

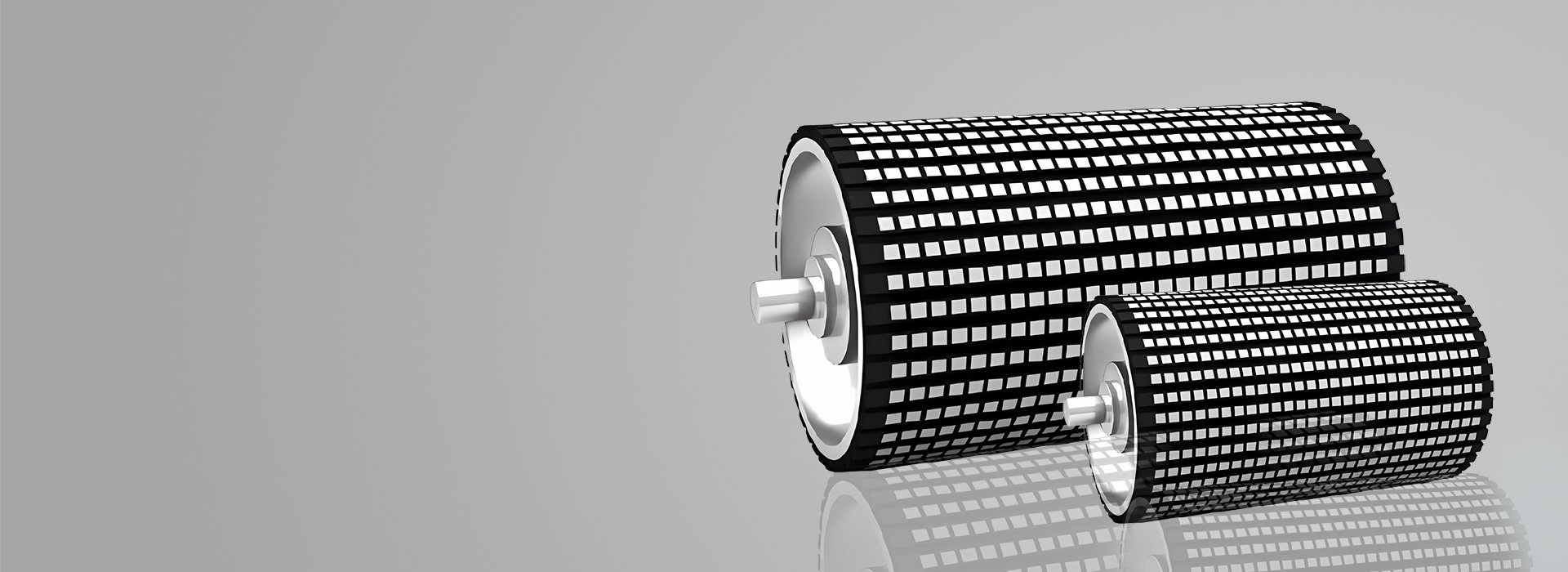

Ceramic Pulley Lagging

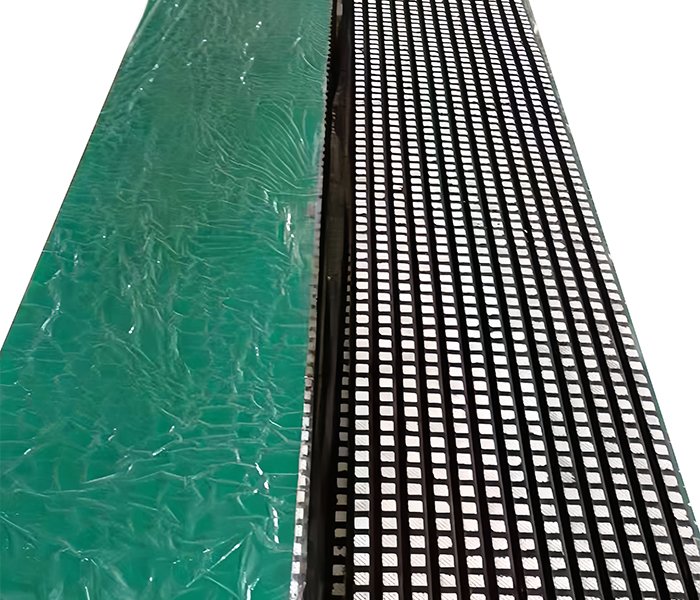

AOBO Ceramic pulley lagging is one of the most commonly used types of lagging applied to conveyor pulleys. Ceramic pulley lagging is essential to improve conveyor belt performance.

Because slippage and excessive wear problems may make ordinary rubber lagging ineffective. Alumina ceramic tiles help to hold the conveyor belt tightly in wet, muddy or any other such difficult conditions because the friction is also relatively high. And because of the special structure of the ceramic surface, AOBO’s pulley lagging can still maintain good anti-slip performance in wet conditions, has good drainage and mud discharge effects, and strong self-cleaning ability. It is often used in harsh conditions where abrasive material is conveyed because the ceramic is harder and more durable than rubber lagging. Indispensable in your project engineering.

For pulley lagging, AOBO New Material company will definitely make you shine, and then choose our products unswervingly. AOBO’s quality and service are top-notch. We will patiently solve your needs and make you feel treated with the utmost sincerity.

2 Types Popular Ceramic Pulley Lagging Specifications

Based on AOBO’s 20 years of industry experience, we suggest these 2 types of ceramic pulley lagging, which are hot-selling grades and specifications in the market, to provide you with professional selection reference.

That is Standard Ceramic Pulley Lagging and FARS Ceramic Pulley Lagging, Difference from Tensile Strength, Hardness, Elongation, Abrasion…

| Rubber Typical Values | Standard | Standard | FARS | Reference Standard |

| Tensile Strength: Mpa | 16 | 20 | 16 | GB/T 528-2009 |

| Hardness: Shore A | 63±5 | 63±5 | 63±5 | GB/T 531.1 |

| Elongation: % | 550% | 600% | 550% | GB/T 528-2011 |

| Abrasion Loss: mm³ | 150 | 110 | 150 | GB/T 9867 |

| Visible Flame Duration: s | N/A | N/A | 1 | MT/T 113 |

| Visible Afterglow Duration: s | N/A | N/A | 80 | MT/T 113 |

| Electrical Resistance (Surface):Ω | N/A | N/A | 3 X 104 | MT/T 113 |

| Continous Operating Temperature: ℃ | -40℃ ~ 80℃ | -40℃ ~ 80℃ | -40℃ ~ 80℃ | |

| Peel Strength: Mpa | 13 | 13 | 13 | GB/T 15254 |

| Aging Test | Tensile Strength +1.0% | Tensile Strength +1.0% | Tensile Strength +0.3% | GB/T 3512 |

| Elongation at Break -8.3% | Elongation at Break -8.3% | Elongation at Break -3.3% |

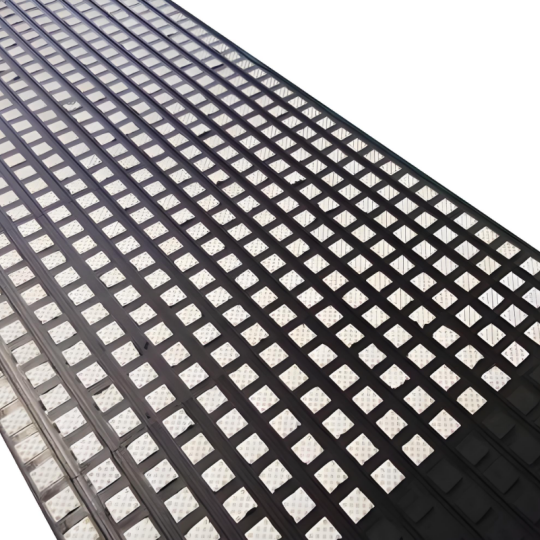

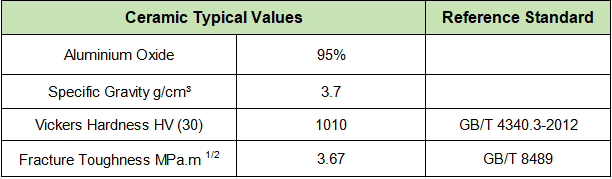

Top Surface: Ceramic typical values, Aluminium Oxide: 95%

Middle: Rubber Material

Bottom: CN-Layer

95% high-purity alumina ceramic blocks have excellent performance: density ≥3.7g/cm³, hardness 3 times that of steel, high compressive strength, resistance to extremely high temperatures, excellent wear resistance, and excellent electrical insulation and acid and alkali resistance. It is an ideal wear-resistant solution for mining machinery, high-temperature equipment and electronic components.

Ceramic Pulley Lagging Available Size

AOBO provides comprehensive rubber pulley lagging size and customization services for size, covering the hot-selling sizes, and available sizes for your reference.

| Ceramic Pulley Lagging | Thickness | Width | Length |

| Standard Type Popular Size | 12mm/15mm | 500mm | 800mm, 1000mm, 1200mm, 1450mm, 1650mm, 1850mm, 2050mm, 2250mm, 2550mm, 10m,etc. |

| FARS Type Popular Size | 12mm/15mm | 500mm | 800mm, 1000mm, 1200mm, 1450mm, 1650mm, 1850mm, 2050mm, 2250mm, 2550mm, 10m,etc. |

| Ceramic chip size | 5mm | 20mm | 20mm |

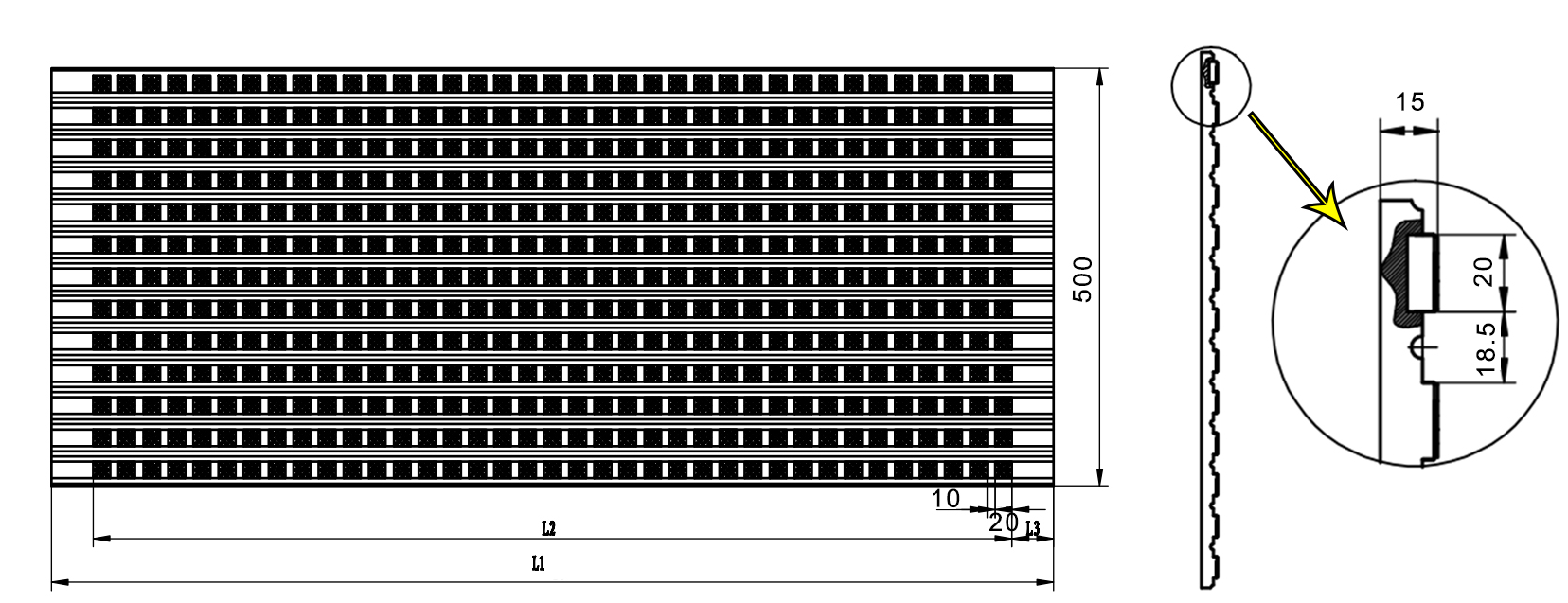

AOBO provides a scientifically arranged ceramic rubber coating design solution, with ceramic sheet spacing accurate to ±0.5mm, maximizing grip and wear resistance!

▸ Ceramic sheet size: commonly 20×20×5mm

▸ Rubber substrate thickness: commonly popular 15mm

Equipped with edge anti-collapse treatment, it is perfectly suitable for extreme working conditions such as mines and steel mills.

Advantages Of Aobo Ceramic Pulley Lagging

- Performance parameters can be recommended according to your project environment

- AOBO can offer ordinary ceramic lagging and flame-retardant ceramic lagging

- AOBO can offer different performances of tensile strength in 15- 22MPa, and can recommend you correct one to help you save money

- There are many sizes and widths for you to choose from, helping you avoid product waste and reduce unnecessary capital waste

- AOBO ceramic pulley lagging has a CN bonding layer, the bonding strength is stronger during the construction process, and provides you with detailed construction guidance

Features Of Aobo Ceramic Pulley Lagging

- Strong wear resistance: The wear resistance and impact resistance of ceramic pulleylagging can resist wear, extend the service life of the drum, and have stable performance under high load conditions.

- Harsh environment: Suitable for extremely harsh conditions such as high wear, easy slippage, and wet materials or surrounding environment. Its good drainage and mud discharge and self-cleaning functions enable it to effectively bond and slip in wet and muddy environments.

- High tear resistance: The semi-vulcanized adhesive layer on the back is easy to bond firmly with the cold adhesive, making it have high adhesion and prevent debonding.

- High chemical corrosion resistance: Ceramic materials are resistant to high temperatures and corrosion and can adapt to harsh working conditions.

- Easy construction: Cold vulcanization lagging technology can be constructed on site, with simple operation and no need for large equipment.

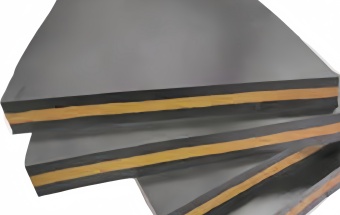

The Self-adhesive CN-Layer Functions

Increase the friction coefficient between the pulley and the conveyor belt, thereby reducing the belt slippage and ensuring the stable operation of the conveying system.

Increase the service life: The design of the CN-layer makes the ceramic pulley surface more wear-resistant, thereby extending the service life of the pulley. The life of the ceramic lagging is 3 to 5 times longer than that of ordinary lagging, reducing the frequency and cost of maintenance.

Enhance the cleaning function: The groove design between the self-adhesive layer and the ceramic block can effectively guide the discharge of foreign matter (such as dust and dirt) on the pulley, enhance the self-cleaning ability of the pulley, and is especially suitable for humid working environments.

Convenient construction: Makes the lagging construction more convenient, without the need to disassemble the pulley, which greatly saves time and cost.

Ultra-Flexible Usage Scenarios Of Aobo Ceramic Pulley Lagging

- Steel industry: The steel production environment is hot and corrosive. AOBO’s Ceramic roller lagging is resistant to high temperature and corrosion and can adapt to harsh working conditions.

- Power industry: The transportation of coal and other granular materials in power plants is prone to roller wear. AOBO Ceramic pulleylagging has stable performance under high load and high wear environment, which can ensure the normal operation of the conveying system.

- Chemical industry: In chemical production, rollers are often exposed to corrosive chemicals.AOBO Ceramic pulley lagging has strong corrosion resistance and can protect the metal surface of the roller from erosion.

Aobo Ceramic Pulley Lagging Is Very Easy To Assemble

- Preparation: Check the appearance of the roller and ceramic rubber sheet to ensure that there are no damage or defects. Prepare tools and materials such as rubber knives, compaction rollers, grinders, cleaning agents, metal primers and adhesives, rubber hammers, etc.

- Drum surface treatment: Use a rubber scraper or angle grinder to remove old glue and impurities, then clean thoroughly with a cleaning agent, and grind with a grinder if necessary to increase surface roughness and improve bonding effect.

- Apply adhesive: First, evenly apply the metal treatment agent on the surface of the roller. After it is completely dry, evenly apply the prepared adhesive on the surface of the roller and the back of the ceramic rubber sheet, and the application area should be larger than the actual rubber coating area. After 30 minutes, apply the adhesive again.

- Paste the ceramic rubber sheet: Paste the ceramic rubber sheet flatly on the surface of the roller, try to get it in place at one time, avoid repeated lamination, and then knock and roll it with a rubber hammer or compaction roller to ensure that there are no bubbles or wrinkles, so that it fits tightly with the roller.

- Wait for curing: The rubber-coated roller needs to be cured naturally, which usually takes more than 24 hours.

If you still don’t know how to assemble, don’t worry, AOBO can provide you with technical guidance .

The hardness of ceramic sheets is 3 times that of ordinary steel, and the wear rate is very low.

The lifespan can reach 5-10 times that of ordinary rubber pulley lagging, and it is usually used for 3-8 years in scenarios such as iron ore and quartz sand.

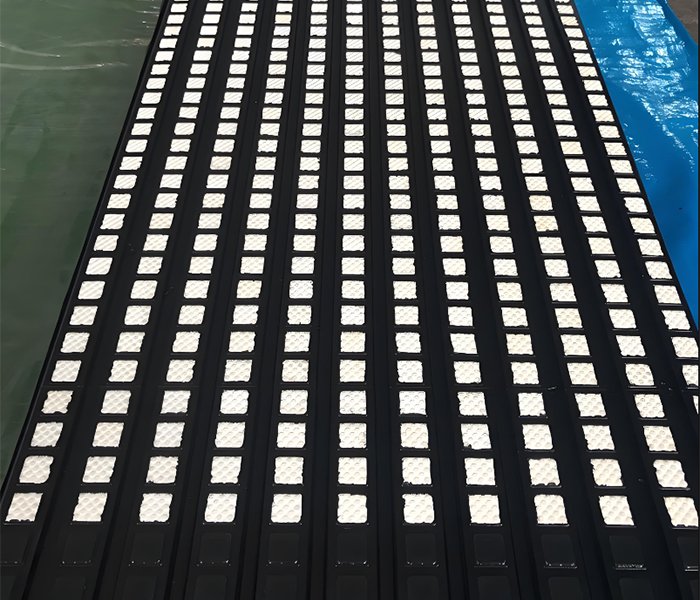

Our company’s products embed ceramics in rubber, which is very strong and durable.

Using the embedded vulcanization process, the bonding strength between the ceramic sheet and the rubber substrate is ≥20MPa;

The surface of the ceramic sheet is pre-engraved with micro-grains to enhance the mechanical bite force and ensure that there is no hollowing.

Cold bonding is not recommended!

Ceramic pulley lagging must be hot-vulcanized to ensure a firm bond between the ceramic sheet and the rubber.

Pre-vulcanized ceramic lagging plates can be provided for on-site drum repair (special glue is required).

Regularly use a high-pressure water gun to remove the accumulated material in the gap between the ceramic sheets.

Avoid scratching with metal tools to prevent the ceramic sheet from breaking the edge.

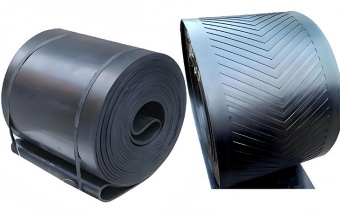

Related Hot Sell Mining Rubber

Diamond pattern, excellent anti-slip and wear resistance, with CN-layer.

Many styles can be chosen. Usually used in heavy industry and infrastructure construction.