AOBO Die Cut Gaskets

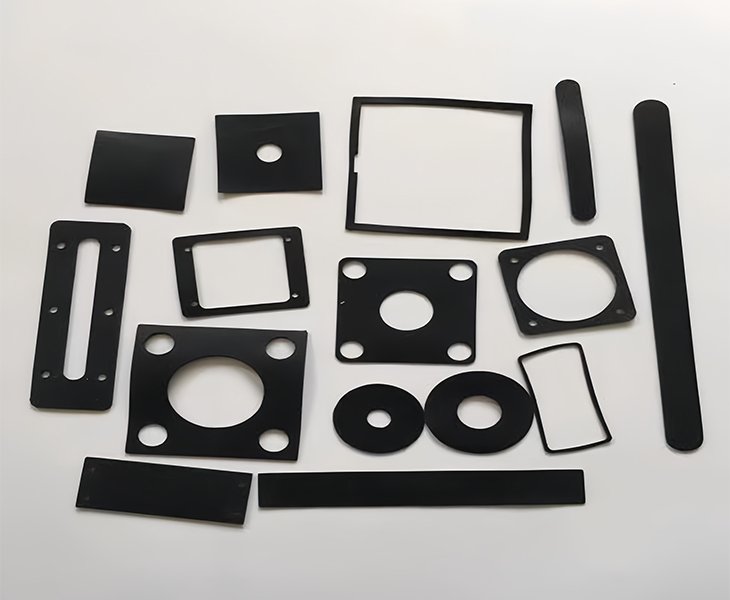

Customized rubber die-cut gaskets refer to rubber gaskets that are processed by die-cutting according to specific needs. Die-cutting is a method of cutting materials using a die. Die-cut gaskets function as a seal between two different surfaces.

If you are struggling to choose die-cut gasket products that can be made according to your wishes, then AOBO New Material company must be your first choice. Our custom die-cut gaskets ensure leak-proof, efficient, and superior performance for critical sealing needs. AOBO has different methods of die cutting depending upon your requirements.

Advantages of AOBO Die Cut Gasket

- Precision Cutting for a Perfect Fit

- Customized Shapes and Sizes can be with a sticker, accurately cut according to the size or drawing you provide.

- Super cost-effective price

- Economical and efficient production

- Materials: Silicone, EPDM, CR, NBR, natural rubber sheet, fluororubber, HNBR, etc.

AOBO Company specializes in die-cut gaskets, offering complete customization with cost-effective solutions to meet your exact application requirements.

AOBO uses advanced cutting technology to ensure accurate dimensions and a perfect fit for any application. always putting your satisfaction first

Characteristics of AOBO Rubber Die-Cut Gaskets

- Diversity of shapes: Customized rubber die-cut gaskets can be cut into various complex shapes according to your needs, suitable for occasions where special-shaped gaskets are required.

- Precision and quality: AOBO die-cutting process has high precision and stable quality, and is suitable for processing parts with complex shapes.

- Scope of application: Accept small batch production

Application Scenarios of AOBO Rubber Die-Cut Gaskets

Die-cut gaskets are precision-cut sealing components used to prevent the leakage of liquids, gases, or contaminants in industrial, automotive, and aerospace applications.

Also can be used as insulation and sealing materials used in Mechanical equipment, engineering projects, and electronic equipment.

AOBO die-cut gaskets are made of environmentally friendly materials. During the production process, we are committed to reducing waste and improving energy utilization, thereby effectively reducing production costs.

This green manufacturing method not only ensures stable product quality and performance but also achieves a double victory of environmental protection and economic benefits, which is truly perfect.

Yes, materials such as PTFE and Nitrile rubber offer excellent resistance to oils, fuels, solvents and harsh chemicals, making them ideal for the chemical processing industry.

- Design mold: Design molds according to your needs to ensure that the shape and size of the cut gaskets meet the requirements.

- Material selection: Select suitable rubber materials such as silicone, NBR, CR etc. to meet your specific performance requirements, such as oil resistance, acid and alkali resistance, cold and heat resistance, etc.

- Die cutting process: Use a die cutter to cut in the mold to produce gaskets.

- Quality inspection: Perform quality inspection on the finished product to ensure that the accuracy and quality meet your standards.

Choosing the right gasket depends on factors such as temperature, pressure, chemical exposure, and compatibility of the material with the sealing environment.