AOBO EPDM Rubber Sheet Performance

- Excellent weather and ozone resistance

- Ultra-thin available, Extra-width Size Available

- Different Grades Available: Commercial Grade EPDM/SBR, Pure EPDM, High Grade Pure EPDM…

- Both sides fabric impression, fabric inserted, or sponge type, all available

- EPDM is particularly suitable for working conditions that require water, weather, and chemical resistance

- EPDM is an ideal choice for outdoor sealing and protection applications, like bridge expansion joints, building sealing strips, etc.

EPDM Rubber Sheet

Are you looking for durable and affordable rubber sheets? AOBO EPDM rubber sheets are the ideal solution for a variety of applications. The main chain of EPDM is fully saturated, with fairly high chemical stability and high thermal stability, and high insulation properties. In addition to this, one of the other outstanding properties of EPDM rubber is its excellent resistance to ultraviolet (UV) radiation, ozone, and oxygen. Since it does not degrade even after long-term exposure to sunlight, it is very suitable for outdoor applications. Its weather resistance and aging resistance ensure that AOBO EPDM Rubber Sheet can maintain a long service life even in harsh conditions.

If you are looking for EPDM rubber sheets, but don’t know how to choose, please feel free to contact me and we will provide you with some professional advice. AOBO professionally provide you all kinds of rubber sheets.

5 Types Popular EPDM Rubber Sheet Specifications

Based on AOBO’s 20 years of industry experience, we suggest these 5 types of EPDM Rubber Sheet, which are hot-selling grades and specifications in the market, to provide you with professional selection reference.

Different grades: based on EPDM content, tensile strength, temperature resistance, and other key indicators.

Each model is accompanied by a detailed technical parameter table and a specific application scenario recommended for use to help you learn more information.

EPDM Rubber Sheet Available Size and Size Tolerance

Professional EPDM Rubber Sheet Size Solutions

AOBO provides comprehensive EPDM Rubber Sheet size and customization services for size, covering the hot-selling sizes, and available sizes for your reference.

| EPDM Rubber Sheet | Thickness(mm) | Width(m) | Length(m) |

| Popular Size | 0.8-1.5mm 2-10mm | 1-1.5m | 10-20m |

| Available Size | 0.4-50mm | 0.2-3m | Any/Customized |

| Ultra Thin | 0.4-1mm | 1-1.2m | Any/Customized |

| Extra Wide | 2-10mm | 2-3m | 10m |

All EPDM rubber sheets are strictly implemented: full-size tolerance control following international standards.

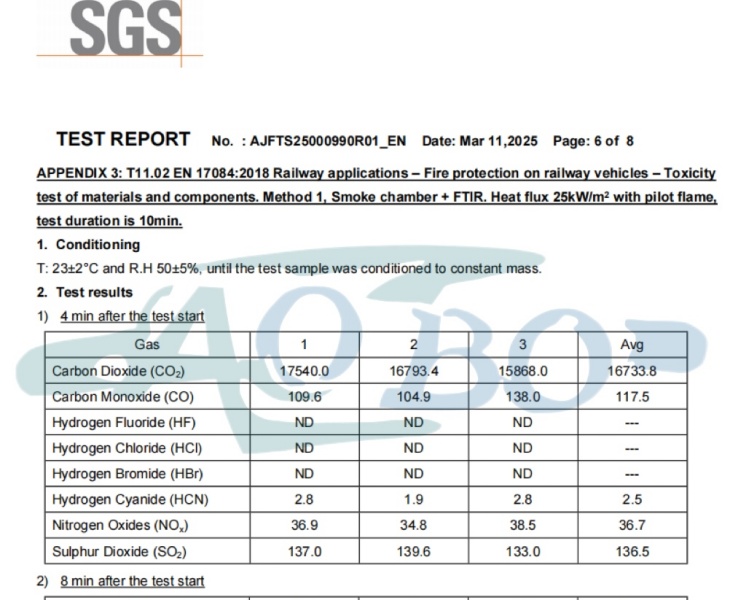

EN45545-2 Fireproof EPDM Rubber Sheet

EPDM material that meets the EN45545-2 fireproof standard. HL2 & HL3 R22& R23.

Smoke density: <200, halogen-free, oxygen index >28 (flame-retardant)

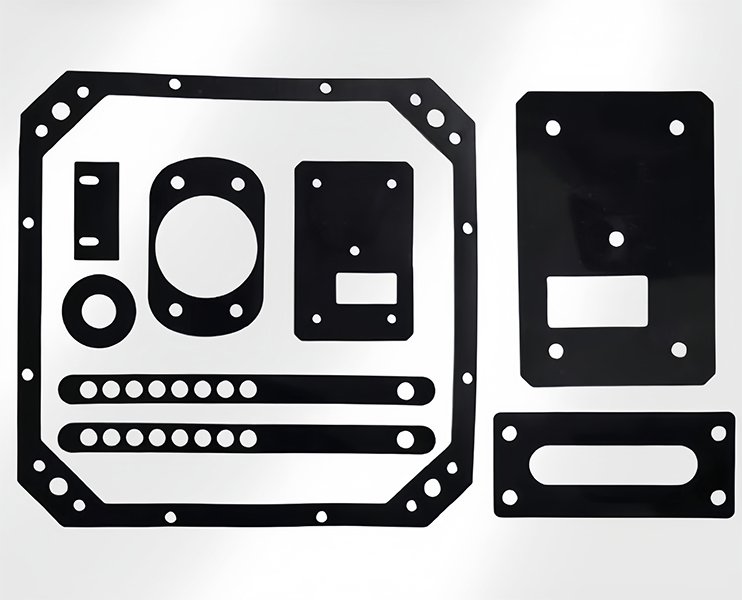

Product use: Railway applications- Fire protection on railway vehicles. Designed specifically for sealing the connection between high-speed rail/EMU carriages, with low smoke and low toxicity, a service life of more than 15 years, and significantly improves the safety and durability of trains.

Aobo Offer Different Specifications For You Choose

- AOBO Special thickness and sizes for you

- Color can be chosen: A Variety of colors are available. The most popular color is black.

- Different Tensile strength, Hardness, and Density available

AOBO professional engineers can also give you professional suggestions based on your specific situation. At the same time, AOBO prides ourself on precision and strictly maintains a tolerance of standard, to ensure that the product you receive meets your exact specifications.

Advantages Of Aobo Epdm Rubber Sheet

- Excellent aging resistance, the best among existing general-purpose rubbers:(1) Ozone resistance and weather resistance(2)Heat aging resistance, generally can be used for a long time at 150°C, and can withstand 200°C for intermittent use

- Excellent electrical insulation performance, exceeding butyl rubber

- Good chemical resistance, with great resistance to various polar chemicals and acids and alkalis, but poor stability to hydrocarbon oils

- Good impact elasticity, up to 50%-60%, second only to butadiene rubber and natural rubber, especially because it has no crystallinity and maintains good elasticity at low temperatures

AOBO EPDM Rubber Sheet has a fairly high chemical stability, acid and alkali resistance, good heat resistance, ozone resistance, and aging resistance; it also has good elasticity, insulation performance and low temperature resistance. Temperature range: -55℃ to 125℃, and can be as high as 150℃ by peroxide vulcanization.

Application Scenarios Of Aobo Epdm Rubber Sheet

EPDM is mainly used in the automotive industry and can be used as a sealing material for automobile weather strips, water tank hoses, heater hoses, car covers, and car baskets, etc.

EPDM rubber sheet has excellent electrical insulation properties and is resistant to high temperatures, so it can be used as the sheath of wires and cables, and other high-voltage and ultra-high-voltage electrical insulation materials.

EPDM can also be made into construction and waterproof materials, used as the substrate of dams and ponds, bridge pier rail pads, etc.

Aobo Provide You With Factory Prices For Epdm Rubber Sheet

AOBO is a professional EPDM rubber sheet manufacturer integrating R&D, production and sales.

For EPDM rubber sheet, AOBO have multiple production equipment, cooperating with us, you can enjoy China ex-factory price directly, which is the lowest price available in the market. With the same quality EPDM rubber sheet, our prices are more competitive, allowing you to gain an advantage in the procurement process and easily expand your business, greatly increase your profit margin, and make you stand out in the market competition.

Comparison of Rubber Temperature Resistant Ranges

This table clearly compares the temperature resistance range of various rubber sheet materials (such as Silicone, NBR, EPDM, FKM, etc.), helping you quickly understand the applicable temperature environment of different materials. Through intuitive data comparison, it can provide professional reference for your product material selection and ensure that excellent performance is maintained under high or low temperature conditions.

Different Rubber Sheet Materials: SBR, CR, EPDM, NBR, FKM, NR, Silicone, CSM, IIR, FVMQ, HNBR

The data is based on ASTM standard testing and is authentic and reliable.

However, in special cases, different formulas can be added to meet your more specific practical application scenarios. Please contact AOBO, and our engineers can provide more detailed material selection suggestions.

Chemical Adaptability of Various Rubber Materials

The chemical compatibility comparison table of AOBO’s rubber sheet materials is as follows: clearly showing the key performance indicators of acid resistance, alkali resistance, oil resistance, etc. of each category (such as NBR, EPDM, FKM, etc.), helping you quickly select the material solution that best matches the working conditions.

Different Rubber Sheet Materials: CR, SBR, EPDM, NBR, IIR, Hypalon, VMQ, HNBR, FKM, FFKM, FVMQ, FEPM, Silicone

Different Chemical Adaptability: Resistant to Acids, Oils, Steam, Ethers, Alcohols, Alkali, Ketones, Amines, Aldehydes.

Divided into 4 Grades: Excellent, Good, Fair, Poor

All data are verified by ASTM standard tests, providing a scientific basis for material selection for your equipment sealing and pipeline applications.

The above parameters are for reference only. Due to the different acids (such as dilute sulfuric acid, hydrochloric acid, acetic acid, etc.), alkalis, oils, and their concentration differences may have different effects on various rubber products. Please confirm with the AOBO technical department for specific tolerance performance.

EPDM Rubber Sheet Packaging

AOBO offers different packaging ways for EPDM Rubber Sheet, you can choose or we can suggest to you.

Packaging According to Your Requirement.

EPDM is usually used in outdoor ventilated environments, and the material itself is safe and non-toxic. However, the smoke produced by EPDM during combustion and manufacturing can cause respiratory problems, so you need to be careful.

EPDM rubber sheet is a very weather-resistant rubber sheet that can resist the effects of weather very well. However, it requires regular maintenance to ensure that it continues to work effectively.

It includes the vulcanization time,temperature and speed.We have special people to control the vulcanize temperature,and professional people to control the press and time according to different products.

Related Hot Sell Rubber Sheets

Natural rubber sheet has best elasticity and high tensile properties/strong tear resistance.

NBR is known for its oil resistance, especially suitable for fuel and lubricating oil environments.

Ultra-wide temperature range (-60℃~230℃), excellent weather resistance, and insulation.

CR has outstanding performance in ozone resistance, weather resistance and flame resistance.