Rendimiento del caucho para minería AOBO

- Disponemos de varios cauchos de minería para diferentes escenarios para que usted elija.

- El SBR/NR de alta calidad es resistente a los impactos, al desgaste y duradero.

- Fácil de instalar y mantener, la guía de instalación

- Precio súper alto y rentabilidad, aumenta tus beneficios a largo plazo

- Necesidades personalizadas para satisfacer diferentes especificaciones de equipos.

Minería de caucho

Cuando piensa en la minería de caucho, definitivamente pensará en la empresa AOBO New Material. El caucho de la empresa AOBO New Material está diseñado para cumplir con los diversos entornos hostiles de la industria minera.

Los productos de AOBO para la industria del caucho le ofrecen una amplia gama de opciones. Puede elegir entre cintas transportadoras de caucho, Cintas transportadoras de PVC, revestimientos de caucho, caucho sándwich, lámina de caucho resistente a la abrasión, y goma del faldónTodos son productos de alta calidad, cada elección es su mejor elección.

AOBO New Material Manufacturer cuenta con una planta de 20.000 metros cuadrados y puede enviar caucho para minería directamente desde la fábrica. Además, realizamos múltiples inspecciones de calidad antes del envío. El objetivo es garantizar que reciba el caucho para minería más perfecto. AOBO New Material Company debe ser su mejor socio en la industria del caucho para minería.

Caucho para minería que protege diversos equipos mineros

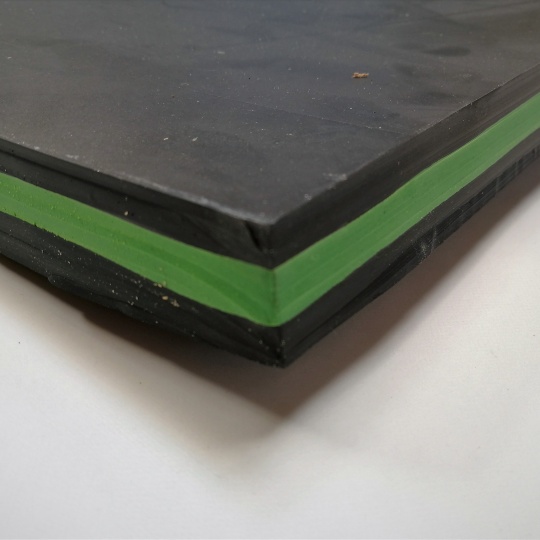

El caucho para minería incluye el caucho utilizado para proteger diversos tipos de equipos mineros, y sus usos son muy diversos. Para este fin se utilizan revestimientos de caucho, láminas de caucho resistentes al desgaste, láminas de caucho sándwich, tableros de caucho, etc. A continuación, se presentan algunos escenarios de aplicación específicos.

Utilizadas en equipos vibratorios, como cribas vibratorias y trituradoras en minas, varias láminas de caucho pueden absorber y ralentizar la vibración generada cuando el equipo está en funcionamiento, reducir los daños al equipo y a los cimientos y prolongar la vida útil del equipo.

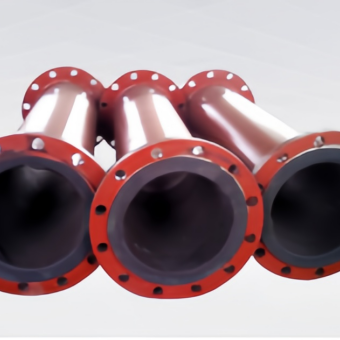

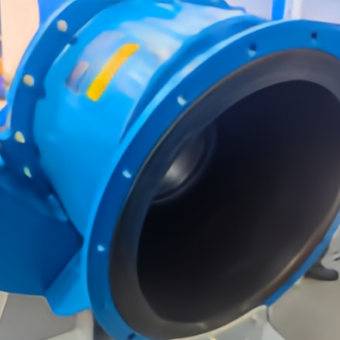

Revestimiento de diversos equipos tales como molinos, maquinas de flotación, trituradoras, ciclones, chutes, silos, bombas de lodos, válvulas de manguito, ciclones, bombas de lodos, válvulas de manguito, tuberías de lodos, etc.

Protección de carcasas de diversos equipos tales como plataformas de amortiguación, motoniveladoras, carros mineros todoterreno, cargadoras, excavadoras, transportadores de banda, etc.

Gracias a su elasticidad, baja dureza, fácil construcción y resistencia al desgaste, las láminas de caucho protegen el equipo contra daños y prolongan su vida útil. Los productos de PU son altamente resistentes al desgaste y a la corrosión, y se utilizan ampliamente en equipos de minería y equipos de transporte para reducir los daños a equipos y cimentaciones. Los materiales de PU se utilizan principalmente para la protección de carcasas de equipos.

Lámina de caucho natural NR, revestimiento de equipos, que protege la pared interior del equipo contra daños y así prolongar la vida útil de la tubería.

El revestimiento de caucho puede resistir eficazmente la erosión de partículas sólidas en la pulpa y los productos químicos, y proteger la tubería del desgaste y la corrosión.

Tiene una excelente flexibilidad y efecto amortiguador, y reduce la erosión y el desgaste de la pared interna de la tubería por el material durante el transporte.

Amortigua el impacto del medio de molienda y el mineral en el cilindro, reduciendo eficazmente el ruido. Además, el revestimiento de goma ofrece buena resistencia al desgaste.

revestimiento de caucho-efecto protector, en equipos de minería, el revestimiento se utiliza para proteger el interior del equipo del impacto y la fricción del mineral.

Lámina de caucho resistente al desgaste o lámina de caucho sándwich, instalada en el balde o alrededor del automóvil, guardabarros, etc., efecto protector, protege el vehículo.

Para evitar que la suciedad, partículas de mineral y otros residuos arrastrados por los neumáticos salpiquen la carrocería del vehículo, los equipos circundantes y el personal.

Bloquea eficazmente la suciedad y las piedras arrastradas por las orugas o los neumáticos durante el proceso de excavación, manteniendo el área de trabajo relativamente limpia.

AOBO le ofrece una variedad de cauchos para minería

AOBO New Material Company es un fabricante y proveedor líder en la industria del caucho. Contamos con 20 años de experiencia en el sector y una amplia experiencia y profundos conocimientos técnicos. La empresa ofrece una gama completa de productos de caucho para minería. Para sectores de alta gama con requisitos de rendimiento exigentes, aquí encontrará los productos de caucho para minería adecuados. Con tantas opciones, podrá elegir la más adecuada.

A continuación te presentamos el caucho minero en detalle.

Las minas incluyen principalmente minas de carbón, minas de metales, minas no metálicas y minas de materiales de construcción, etc. Estas minas necesitan muchos productos de caucho de varios tamaños, muchas variedades y amplias aplicaciones, y algunas tienen requisitos especiales.

Además, la industria minera se caracteriza por la alta carga y un entorno hostil, por lo que el caucho para minería debe ser resistente al desgaste, duradero y resistente a los impactos. La facilidad de instalación y mantenimiento también es fundamental, ya que el costo de las paradas de los equipos mineros es elevado. Cada equipo tiene especificaciones diferentes, por lo que AOBO se centra en satisfacer sus necesidades personalizadas.

Los usos de las láminas de caucho en las minas incluyen principalmente los siguientes aspectos:

| Revestimiento de rodillos | Las láminas de caucho utilizadas para el revestimiento de bandas transportadoras pueden mejorar significativamente la eficiencia del transporte. Por ejemplo, las láminas de caucho antidesgaste con diamante incorporan un diseño de patrón de diamante integrado, que aumenta la fricción, reduce el deslizamiento de la banda, previene la adherencia del material, distribuye uniformemente la presión y prolonga la vida útil. |

| Cinta transportadora | En las minas, se utilizan cintas transportadoras para transportar materiales como minerales y roca estéril. Las cintas transportadoras de caucho son las más comunes. |

| Los revestimientos de caucho se utilizan en trituradoras, diversos molinos y otros equipos. | Este equipo se desgasta y corroe considerablemente durante las operaciones mineras, especialmente al manipular minerales. Los revestimientos de caucho resisten eficazmente el desgaste y la corrosión, protegiendo la estructura interna del equipo contra daños. La resistencia al desgaste del revestimiento de caucho permite un uso prolongado en entornos de trabajo de alta intensidad. |

| revestimientos de tuberías | Durante el transporte y manejo de sedimentos, es muy común el desgaste y la formación de incrustaciones en la pared interior de las tuberías. Los revestimientos de caucho para tuberías pueden prevenir eficazmente este desgaste y la formación de incrustaciones en la pared interior de la tubería, además de contribuir a la absorción de impactos y el aislamiento acústico, mejorando así la vida útil y la eficiencia de producción del equipo. |

| Revestimiento de molino de bolas | El revestimiento de caucho se utiliza ampliamente en molinos de bolas y ofrece ventajas como resistencia al impacto, a la corrosión, al desgaste y bajo nivel de ruido. Reduce eficazmente la fricción y el desgaste del equipo durante su funcionamiento, prolonga su vida útil, reduce los costos de mantenimiento y mejora su eficiencia operativa. |

| Lámina de caucho amortiguadora | Se utiliza para la absorción de impactos y la reducción de ruido en equipos de minería. Presenta buena resistencia al impacto y requiere cierta resistencia al desgaste. |

| Juntas de goma y tiras de sellado | Se utiliza en sistemas de ventilación, drenaje y eliminación de polvo en minas. Las tiras de sellado más comunes incluyen tiras de sellado de caucho de silicona, tiras de sellado de EPDM, tiras de sellado de caucho de cloropreno, etc. |

| Hoja de criba vibratoria | Se refiere a la placa de cribado utilizada para cribar y clasificar materiales sólidos como carbón y minerales, ampliamente utilizada en la industria minera del carbón. La placa de cribado vibratoria está hecha de caucho, tiene buena resistencia a los impactos y al desgaste, reduce eficazmente el ruido de vibración del equipo y mejora la eficiencia del cribado. |

| Goma de protección del equipo | Láminas de caucho resistentes al desgaste y láminas sándwich, placas de poliuretano, etc. El efecto protector del equipo de minería, sus características de resistencia al desgaste, pueden extender efectivamente la vida útil del equipo y reducir el costo general de mantenimiento. |

| Lámina de caucho o PU para zócalo | Se utiliza para bandas de reparación de caucho de bandas transportadoras, revestimientos antidesbordamiento de faldones, capas de caucho resistentes al desgaste y capas de refuerzo. Permite reparar rápidamente rasgaduras y rayones en la banda transportadora, garantizando así la eficiencia de la producción. También se utiliza para reducir la fricción y las pérdidas en maquinaria y equipos. |

| Manguera de goma | Transporte de lodos, relaves y partículas de grava. En minería y extracción de arena y grava, se utilizan mangueras de gran diámetro resistentes a ácidos y álcalis para el transporte de lodos, relaves y partículas de grava. Además, se utilizan mangueras de caucho en sistemas de drenaje e hidráulicos. |

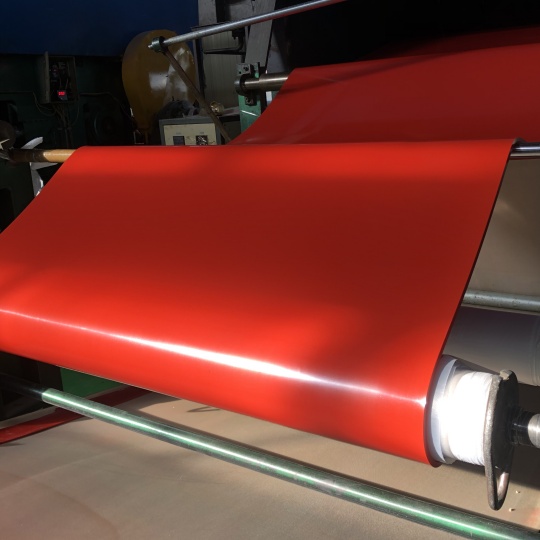

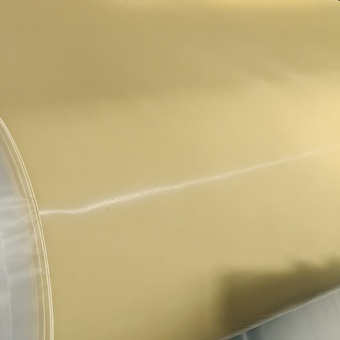

Lámina de revestimiento de caucho Colores disponibles a elegir

Hay muchos colores diferentes para que usted elija para los revestimientos naturales en las minas, y también se pueden personalizar según sus requisitos.

Por lo general, los siguientes colores son los más populares: R1038 Rojo, Bronceado, Marrón, Rojo Brillante, Rojo Anaranjado…

En algunos casos, los colores también se pueden usar para distinguir diferentes piezas o áreas, facilitando así la instalación y el mantenimiento. Los revestimientos de caucho de diferentes colores ofrecen diferentes rendimientos para satisfacer diferentes necesidades de uso.

Lámina de revestimiento de caucho en color beige

Lámina de revestimiento de caucho en color beige Lámina de revestimiento de caucho en color tostado

Lámina de revestimiento de caucho en color tostado Lámina de revestimiento de caucho en color marrón

Lámina de revestimiento de caucho en color marrón Lámina de revestimiento de caucho en azul

Lámina de revestimiento de caucho en azul Lámina de revestimiento de caucho en color rojo R1038

Lámina de revestimiento de caucho en color rojo R1038 Lámina de revestimiento de caucho en color naranja-rojo

Lámina de revestimiento de caucho en color naranja-rojo Lámina de revestimiento de caucho en color naranja-amarillo

Lámina de revestimiento de caucho en color naranja-amarillo Lámina de revestimiento de caucho en rojo brillante

Lámina de revestimiento de caucho en rojo brillante

Su mejor socio de caucho para minería

Cuando selecciona proveedores de láminas de caucho para equipos de minería, entendemos que su decisión es mucho más que la cotización actual.

La lámina de caucho para minería AOBO adopta una fórmula resistente al desgaste de alto grado, que reduce el costo de minería por tonelada y al mismo tiempo extiende la vida útil del producto en más de 30%, de modo que la frecuencia del tiempo de inactividad y el reemplazo del equipo está directamente relacionada con sus beneficios a largo plazo.

Como fabricante con certificación ISO 9001 y de seguridad minera, contamos con un equipo de respuesta global disponible las 24 horas, los 7 días de la semana, para acompañarle desde la confirmación de los detalles del caucho para minería hasta la guía de instalación. Todos nuestros productos han superado las pruebas de protección ambiental RoHS y REACH, y se entregan a tiempo con calidad y cantidad garantizadas, lo que contribuye a la estabilidad de su proyecto minero en todo momento.

Aobo: Servicio íntimo y profesional de extracción de caucho

El caucho para minería de la empresa AOBO New Material se puede personalizar para brindarle una variedad de caucho para minería.

Con nuestra amplia experiencia en el mercado, nuestro equipo profesional e ingenieros pueden brindarle el asesoramiento más profesional, identificar problemas potenciales y recomendar diferentes parámetros de rendimiento según su entorno de uso específico.

Por ejemplo, AOBO puede producir productos con diferentes rendimientos de 6 a 20 MPa, pero recomendará la resistencia a la tracción específica según el entorno de su construcción para ayudarle a reducir el gasto innecesario. AOBO también considera el tamaño de su rodillo para elegir productos de diferentes anchos, evitando así el desperdicio de producto y ahorrándole costos.

Caucho para minería de alta calidad y gran resistencia al desgaste

Antes de la salida final, el caucho de minería de Aobo se someterá a múltiples lavados y múltiples extrusiones para garantizar la absoluta alta calidad y resistencia al desgaste para ofrecerle una vida útil ultralarga del caucho de minería.

Métodos de prueba para productos resistentes al desgaste como referencia: se suelen utilizar el método del probador de desgaste Akron y el método del probador de desgaste de tambor giratorio. Productos de caucho para la protección de equipos mineros: se suele utilizar 10 N para probar la resistencia al desgaste. El entorno de trabajo de los equipos mineros es riguroso. Por ejemplo, el caucho protector de la trituradora de mineral debe resistir el impacto y la fricción del mineral, y la presión es muy alta. La prueba de 10 N puede simular las condiciones reales de trabajo de alta presión y alto desgaste.

Combina con cintas transportadoras y cribas

La mayor parte de este caucho de minería funcional son láminas de caucho resistentes al desgaste y láminas tipo sándwich para que usted elija.

1- Cama amortiguadora de la cinta transportadora: La cama amortiguadora compuesta de láminas de caucho resistentes al desgaste puede amortiguar eficazmente el impacto del mineral y proteger la cinta transportadora contra daños.

2- Protección de bordes de cinta transportadora: Como tira protectora.

3- Raspador limpiador de cinta transportadora: Se utiliza para eliminar partículas de mineral y polvo adheridos a la cinta transportadora.

4- Protección de la pantalla: La instalación de placas de caucho resistentes al desgaste alrededor de la pantalla vibratoria puede evitar que el mineral se desborde del borde de la pantalla durante el cribado y evitar la colisión directa entre el mineral y el marco de la pantalla.

5- Soporte de absorción de impactos de la pantalla: La lámina de caucho resistente al desgaste utiliza su elasticidad y resistencia al desgaste para absorber la energía de vibración de la pantalla vibratoria, reducir la transmisión de vibración a la estructura de la base y desempeñar un papel de absorción de impactos.

El caucho en la industria minera se presenta en diferentes tipos. El caucho de protección de equipos puede proteger maquinaria y equipos grandes en minas, así como transportar piedras extraídas, sal y otros materiales. El PU y el caucho filtran los materiales extraídos de diferentes tamaños según sus necesidades. También contamos con diferentes revestimientos para poleas y cintas transportadoras para su elección.

Sí. El caucho para minería está hecho de varios tipos de caucho, y puedes elegir el caucho apropiado según su corrosividad.

Sí. Las propiedades más básicas del caucho para minería son la resistencia al desgaste y la tenacidad. Es ideal para trabajos mineros básicos, y las necesidades especiales de minería requieren caucho especial.