AOBO Insertion Rubber Sheet Performance

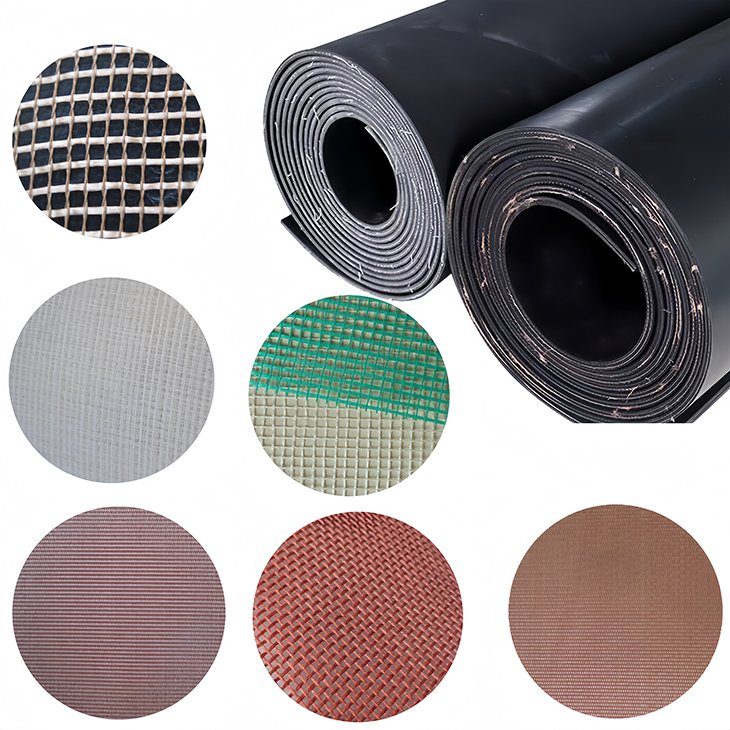

- AOBO can provide you with a variety of fabrics to choose from: cotton gauze, nylon, nylon and polyester cross cloth, polyester cloth, glass fiber cloth, aramid cloth, and steel wire rope.

- Rubber material can be SBR, SBR/NR, CR, EPDM, NBR, FKM…

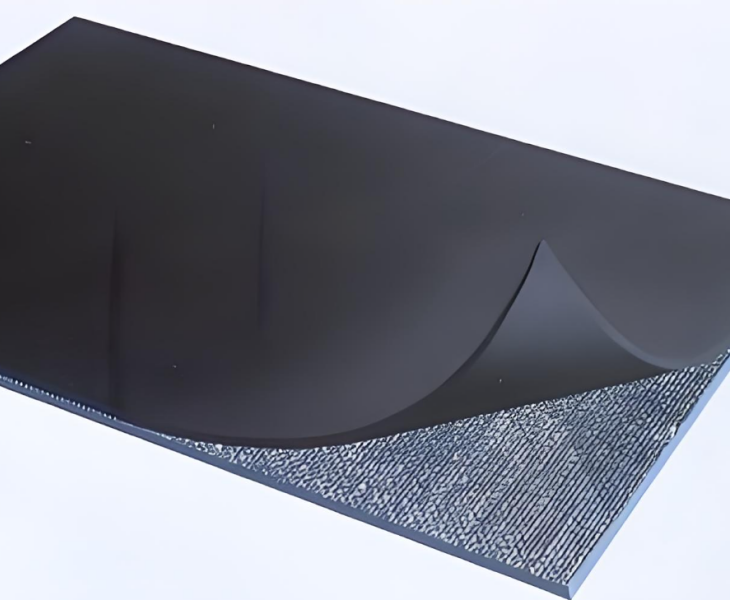

- Surface (smooth surface/cloth pattern combination)matching application: double-sided smooth surface (low friction seal), double-sided fabric impression pattern (high anti-slip), single-sided smooth pattern (composite functional requirements).

- It can be one-layer or multi-layer cloth inserted to increase strength and tear resistance.

AOBO Insertion Rubber Sheet

The AOBO insertion rubber sheet/ fabric reinforced rubber sheet is a composite material made of rubber and cloth bonded by high temperature and high pressure or hot vulcanization technology. This structure makes the rubber sheet have the elasticity and wear resistance of rubber and the strength and stability of cloth.

AOBO provides you with a variety of insertion rubber sheets to choose from or can customized according to your specific needs. If you don’t know how to choose, please rest assured that our professional sales staff will give you the most professional advice. AOBO has a professional engineer team, a passionate sales team, and a perfect after-sales service team. AOBO will provide you with one-stop service.

If you are interested, contact us now.

4 Types Popular Insertion Rubber Sheet Specifications

Full range of rubber material coverage: Rubber types suitable for different working conditions:

General type: SBR (economical and durable), SBR/NR mixed (balanced elasticity and strength)

Special rubber: EPDM (ozone/weather resistant), NBR (oil resistant), CR (acid and alkali resistant), FKM (high temperature resistant 250°C+)…

Based on AOBO’s 20 years of industry experience, for each rubber material, we recommend the following four popular indicators and specifications in the market, which can provide you with professional selection reference.

AOBO also provides different grades of rubber sheets with a tensile strength of up to 2MPa and hardness ranging from 50±5 to 80±5 Shore A.

Insertion Rubber Sheet Available Size & Tolerance

Professional Insertion Rubber Sheet Size Solutions

AOBO provides comprehensive Insertion Rubber Sheet size and customization services for size, covering the hot-selling sizes, and available sizes for your reference.

| Insertion Rubber Sheet | Thickness(mm) | Width(m) | Length(m) |

| Popular Size | 1.6 mm (1/16″) 2-10mm | 1-1.5m | 10-20m |

| Available Size | 1.5-50mm | 0.2-2m | Any/Customized |

| Zikou Nylon Fabric Size | 0.55±0.05mm | 1.4m | Any |

| EP100 Fabric Size | 0.45/0.46±0.05mm | 1.7m/2.15m | Any |

All Insertion rubber sheets are strictly implemented: full-size tolerance control following international standards.

Advantages of AOBO Insertion Rubber Sheet

- Customization on demand: flexible configuration of material/size/surface treatment in all dimensions.

- Insertion rubber sheets are exported to 30+ countries, including Europe, America, and the Middle East, serving 500+ industrial customers.

- The insertion rubber sheet has a variety of fabrics to select from.

AOBO provides multiple types of fiber reinforcement layers to meet the needs of different industrial scenarios:

Basic type: cotton gauze (breathable and wear-resistant), grid red cloth (cost-effective)

High-strength type: large mesh cloth (tear-resistant), zikou Nylon cloth (uniform force)

Special use: EP cloth (chemical corrosion resistance), steel wire/iron plate composite (ultra-high pressure environment) - AOBO insert rubber sheet has good tensile strength and tear resistance, good durability, and can withstand medium pressure, and small deformation, in addition to good cushioning and shock absorption effect. It can withstand extreme working pressure and wear conditions to ensure long-term stable operation.

AOBO How to Control the Insertion Rubber Sheet Production Process

The production process of rubber sheets mainly includes the following steps:

- Material preparation, plasticizing, mixing, molding, vulcanization, finishing, quality inspection.

- Each process has different requirements for the product, and each process is combined with a number of auxiliary operations.

- There are three key factors in the production of insertion rubber sheets: Vulcanization time, vulcanization temperature, and pressure.

- AOBO has special people to control the vulcanize temperature, and professional people to control the press and time according to different products.

Characteristics of Various Fabrics

1. Cotton cloth: a fabric woven with natural cotton as raw material. It has good moisture absorption and breathability, high softness, and good bonding with rubber. Adding cotton cloth to rubber products can increase the strength and toughness of rubber products while reducing costs.

2. Zikou Nylon cloth: also called polyamide fiber cloth. Advantages: It has high strength and wear resistance, strong tear resistance, good elasticity, and can withstand greater pressure and friction.

3. Polyester and nylon interwoven canvas, also known as EP cloth: has the advantages of combining the advantages of polyester and nylon, with high strength, good tensile resistance, good fatigue resistance, and certain flexibility.

4. Glass fiber cloth: It has the advantages of high temperature resistance, corrosion resistance, high strength, and good insulation. Its strength is very high, which can significantly improve the strength and rigidity of rubber products, and it has good dimensional stability and heat resistance.

Application Scenarios of AOBO Insertion Rubber Sheet

AOBO insertion rubber sheet is widely used in many industrial fields due to its unique performance advantages.

AOBO insertion rubber sheet has the characteristics of high strength and wear resistance, so it is used for seals, gaskets, cushions, etc. in mechanical equipment, providing good sealing effect while effectively protecting the equipment. In addition, AOBO insertion rubber sheet can also be used to make waterproof, shockproof, and soundproof materials in building structures, gaskets, seals, and pipe linings in chemical equipment.

How to Choose Which Cloth to Insert?

- Cotton cloth use environment: often used in some rubber products that do not have particularly high requirements for strength and wear resistance, such as ordinary rubber seals, rubber liners, etc.

- Zikou Nylon fabric use environment: an environment that needs to withstand frequent bending, stretching, and friction.

- EP cloth use environment: widely used in general industrial conveyor belts, such as in conveyor belts for ordinary material transportation as a skeleton material, such as some cement plants, sand fields, etc., which have requirements for conveyor belt strength, but the working environment is not too harsh.

- Glass fiber cloth use environment: used in some rubber products that have high requirements for high temperature resistance, corrosion resistance, and strength, such as high temperature seals, anti-corrosion rubber linings, etc.

Comparison of Rubber Temperature Resistant Ranges

This table clearly compares the temperature resistance range of various rubber sheet materials (such as Silicone, NBR, EPDM, FKM, etc.), helping you quickly understand the applicable temperature environment of different materials. Through intuitive data comparison, it can provide professional reference for your product material selection and ensure that excellent performance is maintained under high or low temperature conditions.

Different Rubber Sheet Materials: SBR, CR, EPDM, NBR, FKM, NR, Silicone, CSM, IIR, FVMQ, HNBR

The data is based on ASTM standard testing and is authentic and reliable.

However, in special cases, different formulas can be added to meet your more specific practical application scenarios. Please contact AOBO, and our engineers can provide more detailed material selection suggestions.

Chemical Adaptability of Various Rubber Materials

The chemical compatibility comparison table of AOBO’s rubber sheet materials is as follows: clearly showing the key performance indicators of acid resistance, alkali resistance, oil resistance, etc. of each category (such as NBR, EPDM, FKM, etc.), helping you quickly select the material solution that best matches the working conditions.

Different Rubber Sheet Materials: CR, SBR, EPDM, NBR, IIR, Hypalon, VMQ, HNBR, FKM, FFKM, FVMQ, FEPM, Silicone

Different Chemical Adaptability: Resistant to Acids, Oils, Steam, Ethers, Alcohols, Alkali, Ketones, Amines, Aldehydes.

Divided into 4 Grades: Excellent, Good, Fair, Poor

All data are verified by ASTM standard tests, providing a scientific basis for material selection for your equipment sealing and pipeline applications.

The above parameters are for reference only. Due to the different acids (such as dilute sulfuric acid, hydrochloric acid, acetic acid, etc.), alkalis, oils, and their concentration differences may have different effects on various rubber products. Please confirm with the AOBO technical department for specific tolerance performance.

Insertion Rubber Sheet Packaging

AOBO offers different packaging ways for Insertion Rubber Sheet, you can choose or we can suggest to you.

Packaging According to Your Requirement.

The following are the thicknesses of various fabrics in mm:

EP80 0.45±0.05

EP100 0.45±0.05

EP150: 0.68±0.1

EP200: 0.8±0.08

Zikou Nylon-cloth: 0.5±0.05

Brown silk cloth: 0.55±0.05

Cotton gauze: 0.2±0.05

Large mesh: 1±0.05

For insertion rubber sheet, usually there are 1 layer of cloth, 2 layers of cloth, or 3 layers of cloth.

Yes. In outdoor environments, whether in harsh weather conditions or frequent mobile use, the Garment Rubber Sheet can maintain stable performance and appearance.

- First, you need to prepare the two raw materials, rubber and cloth.

- The choice of rubber is usually determined according to the use environment and needs, which can be natural rubber, nitrile rubber, chloroprene rubber, etc. The choice of cloth is more diverse, which can be various types of fabrics such as polyester, nylon, cotton, etc. These fabrics have their own advantages and characteristics and can be selected according to actual needs.

- The process of bonding rubber and cloth requires a special adhesive-adhesive. There are many types of adhesives, including solvent-based, emulsion-based, hot-melt-based, etc. When choosing an adhesive, you need to consider factors such as its compatibility with rubber and cloth and the bonding effect. Generally speaking, emulsion-based adhesives are more suitable for the production of cloth-added rubber sheets.

- With the right rubber, cloth and adhesive, you can start making “cloth-added” rubber sheets. This process needs to be carried out under high temperatures and high pressure to ensure that the bonding between rubber and cloth is firm and uniform. Specifically, the rubber and cloth coated with adhesive are stacked together, and then placed in a mold and heated and pressurized. Under the action of high temperature and high pressure, the rubber will soften and fit tightly with the cloth to form a new whole. Finally, after cooling, shaping, cutting, and trimming, we can get the “cloth-added” rubber sheet we want.

Related Hot Sell Rubber Sheets

CR has outstanding performance in ozone resistance, weather resistance and flame resistance.

NBR is known for its oil resistance, especially suitable for fuel and lubricating oil environments.