AOBO Nitrile Rubber Sheet Performance

- NBR is known for its oil resistance and is particularly suitable for fuel and lubricating oil environments.

- Ultra-thin available, Extra-width size available

- Different Grades Available: Commercial Grade NBR/SBR, Pure NBR, High Grade Pure NBR…

- Can be with different fabrics inserted

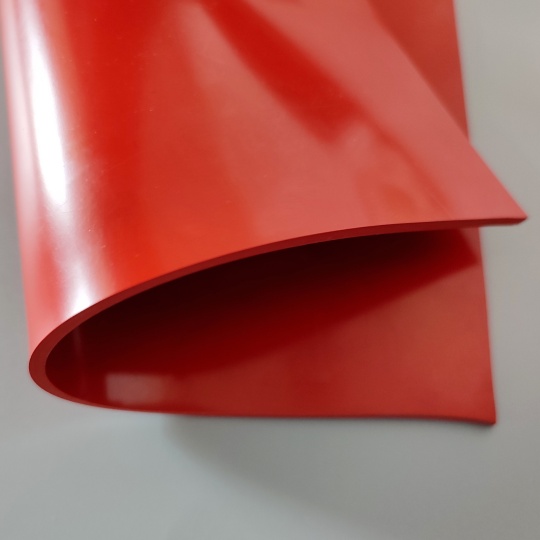

- Both sides fabric impression/ Both sides smooth/ One side smooth, the other side fabric impressed

Nitrile Rubber Sheet

AOBO NBR rubber sheets have excellent oil resistance, wear resistance and other properties, and play an important role in places where oil resistance is required, such as the oil industry, also suitable for various industrial applications.

AOBO New Material Co., Ltd has more than 20 years of experience in the production of NBR rubber sheet. We are constantly updating equipment and technology to provide you with the different grade rubber sheets to meet your different usage. Same quality we win price, same price we win quality, same price and quality we win service.

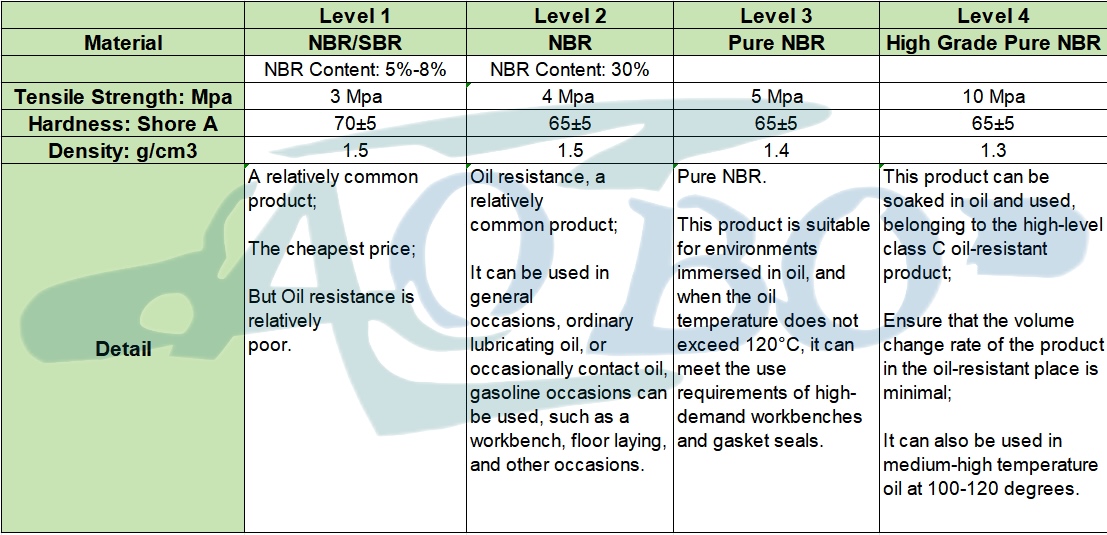

4 Types Popular Nitrile Rubber Sheet Specifications

Based on AOBO’s 20 years of industry experience, we suggest these 4 types of Nitrile Rubber Sheet, which are hot-selling grades and specifications in the market, to provide you with professional selection reference.

Different grades: based on NBR content, tensile strength, and other key indicators.

Each model is accompanied by a detailed technical parameter table and a specific application scenario recommended for use to help you learn more information.

Nitrile Rubber Sheet Available Size & Tolerance

Professional Nitrile Rubber Sheet Size Solutions

AOBO provides comprehensive Nitrile Rubber Sheet size and customization services for size, covering the hot-selling sizes, and available sizes for your reference.

| Nitrile Rubber Sheet | Thickness(mm) | Width(m) | Length(m) |

| Popular Size | 0.8-1.5mm 2-10mm | 1-1.5m | 10-20m |

| Available Size | 0.4-50mm | 0.2-3m | Any/Customized |

| Ultra Thin | 0.4-1mm | 1-1.2m | Any/Customized |

| Extra Wide | 2-10mm | 2-3m | 10m |

All Nitrile rubber sheets are strictly implemented: full-size tolerance control following international standards.

Different Specifications For You Choose

- AOBO Special thickness and sizes for you

- Color can be chosen: A Variety of colors are available. The most popular color is black.

- Different Tensile strength, Hardness, and Density available

AOBO professional engineers can also give you professional suggestions based on your specific situation. At the same time, AOBO pride ourselves on precision and strictly maintains a tolerance of standard, to ensure that the Nitrile Rubber Sheet you receive meets your exact specifications.

Key Features of NBR Rubber Sheets

- Oil resistance: if you want choose oil-resistant rubber sheet, AOBO NBR rubber sheet is your best choice.

AOBO Nitrile rubber has excellent resistance to petroleum and fuel, and is usually used for mineral oil or mineral grease. When working in oily media, nitrile rubber sheet can effectively resist the erosion of oil and maintain its original performance. But it cannot be used for aromatic hydrocarbons, chlorocarbons and polar oils and polar solvents, such as methanol and ethanol.

The N265 model has a 22% acrylonitrile content, and the N41 model has a 35% acrylonitrile content. The higher the acrylonitrile content, the better the oil resistance, but its elasticity and permanent compression deformation rate at low temperatures become worse.

- Heat resistance: AOBO NBR Rubber Sheet temperature range is -20℃ to 100℃ (125℃ for a short time) and it can still maintain its stable performance and is not easy to deform. The low temperature performance is poor; the specially formulated nitrile rubber can be used in an environment of -60℃.

- Wear resistance: Excellent wear resistance and good mechanical properties. Although nitrile rubber sheet is not the hardest rubber sheet, it has relatively good wear resistance.

- The weather resistance and ozone resistance of nitrile rubber are not strong. Some special formulas such as alloy nitrile, that is, nitrile rubber/polyvinyl chloride mixture, have good weather resistance and ozone resistance, but the permanent compression deformation rate is poor.

Application Scenarios Of Aobo Nitrile Rubber Sheet

If you want to make oil-resistant and solvent-resistant rubber products, AOBO Nitrile rubber sheet can meet all your requirements.

It is widely used in the industrial and mechanical industries as a rubber gasket or rubber oil seal. And in the automotive industry, aerospace industry, and oil well industry. AOBO Nitrile rubber is mainly used to make oil pipes, mailboxes, diaphragms, gasket oil linings, oil filters, special products for oil wells (such as blowout preventers, pipeline protection devices), etc.

In addition, AOBO nitrile rubber sheet can also be used to make equipment linings, industrial rubber rollers, printing rubber plates, textile rubber rings, oil-resistant rubber tapes and rubber shoes, sponges, gloves, adhesives, modifiers, and heat-resistant rubber parts.

Comparison of Rubber Temperature Resistant Ranges

This table clearly compares the temperature resistance range of various rubber sheet materials (such as Silicone, NBR, EPDM, FKM, etc.), helping you quickly understand the applicable temperature environment of different materials. Through intuitive data comparison, it can provide professional reference for your product material selection and ensure that excellent performance is maintained under high or low temperature conditions.

Different Rubber Sheet Materials: SBR, CR, EPDM, NBR, FKM, NR, Silicone, CSM, IIR, FVMQ, HNBR

The data is based on ASTM standard testing and is authentic and reliable.

However, in special cases, different formulas can be added to meet your more specific practical application scenarios. Please contact AOBO, and our engineers can provide more detailed material selection suggestions.

Chemical Adaptability of Various Rubber Materials

The chemical compatibility comparison table of AOBO’s rubber sheet materials is as follows: clearly showing the key performance indicators of acid resistance, alkali resistance, oil resistance, etc. of each category (such as NBR, EPDM, FKM, etc.), helping you quickly select the material solution that best matches the working conditions.

Different Rubber Sheet Materials: CR, SBR, EPDM, NBR, IIR, Hypalon, VMQ, HNBR, FKM, FFKM, FVMQ, FEPM, Silicone

Different Chemical Adaptability: Resistant to Acids, Oils, Steam, Ethers, Alcohols, Alkali, Ketones, Amines, Aldehydes.

Divided into 4 Grades: Excellent, Good, Fair, Poor

All data are verified by ASTM standard tests, providing a scientific basis for material selection for your equipment sealing and pipeline applications.

The above parameters are for reference only. Due to the different acids (such as dilute sulfuric acid, hydrochloric acid, acetic acid, etc.), alkalis, oils, and their concentration differences may have different effects on various rubber products. Please confirm with the AOBO technical department for specific tolerance performance.

Nitrile Rubber Sheet Packaging

AOBO offers different packaging ways for Nitrile Rubber Sheet, you can choose or we can suggest to you.

Packaging According to Your Requirement.

The main raw materials of nitrile rubber are butadiene and acrylonitrile.

When choosing the thickness and width of nitrile rubber sheet, you need to consider factors such as the specific application scenario, the required pressure, and the installation space. For example, in situations where higher wear resistance and pressure bearing capacity are required, you can choose a thicker nitrile rubber sheet. Our professional sales staff will recommend the appropriate size for you according to your needs.

It includes the vulcanization time,temperature and speed.We have special people to control the vulcanize temperature,and professional people to control the press and time according to different products.

Related Hot Sell Rubber Sheets

Ultra-wide temperature range (-60℃~230℃), excellent weather resistance, and insulation.

CR has outstanding performance in ozone resistance, weather resistance and flame resistance.

High-quality, versatile, and high-performance rubber sheet material that is widely recognized.