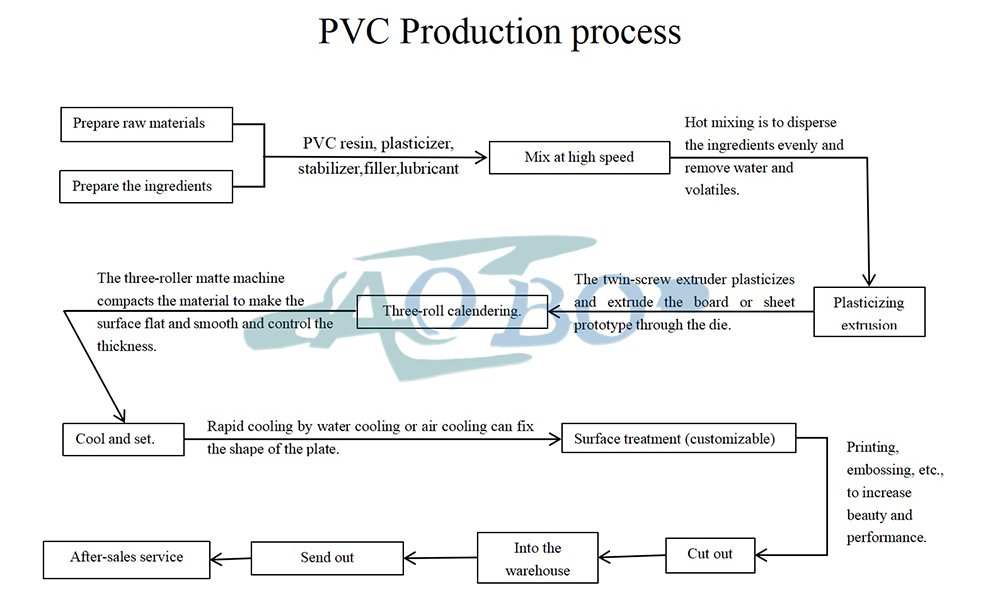

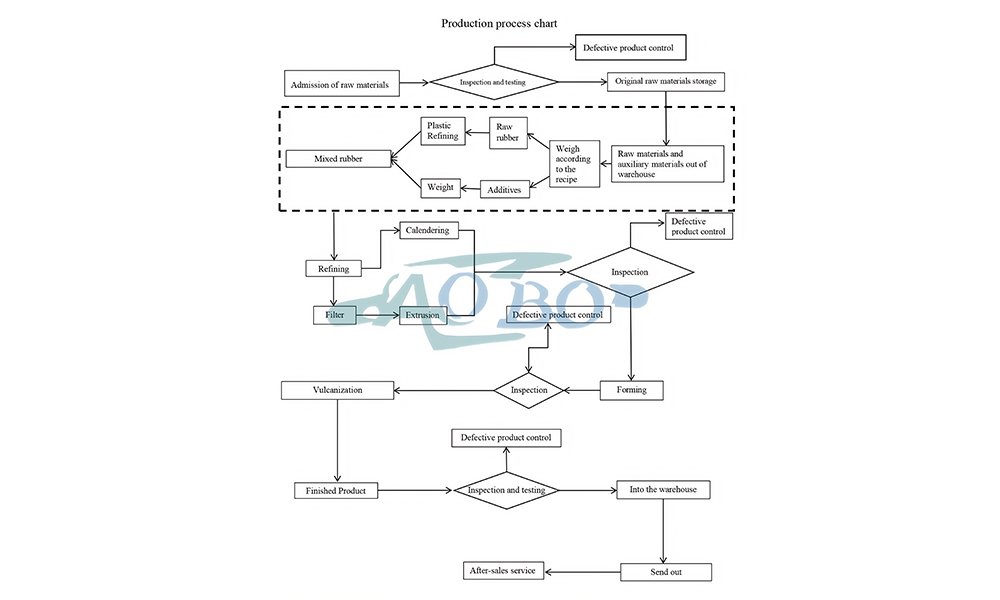

Rubber Sheet Production Process

The rubber sheet production process includes raw material preparation, plasticizing, mixing, refining, calendering, molding, vulcanization, cutting, inspection, packaging, and warehousing.

- Plasticizing, mixing, and refining are the processes of refining raw rubber and compounding agents into mixed rubber through a rubber mixer, which is the most important production process for rubber processing. In this process, various compounding agents, such as fillers, reinforcing agents, accelerators, vulcanizers, antioxidants, etc., need to be added to the raw rubber. These compounding agents include solid and liquid materials. The various compounding agents added are evenly dispersed to ensure the consistency of the properties of the rubber.

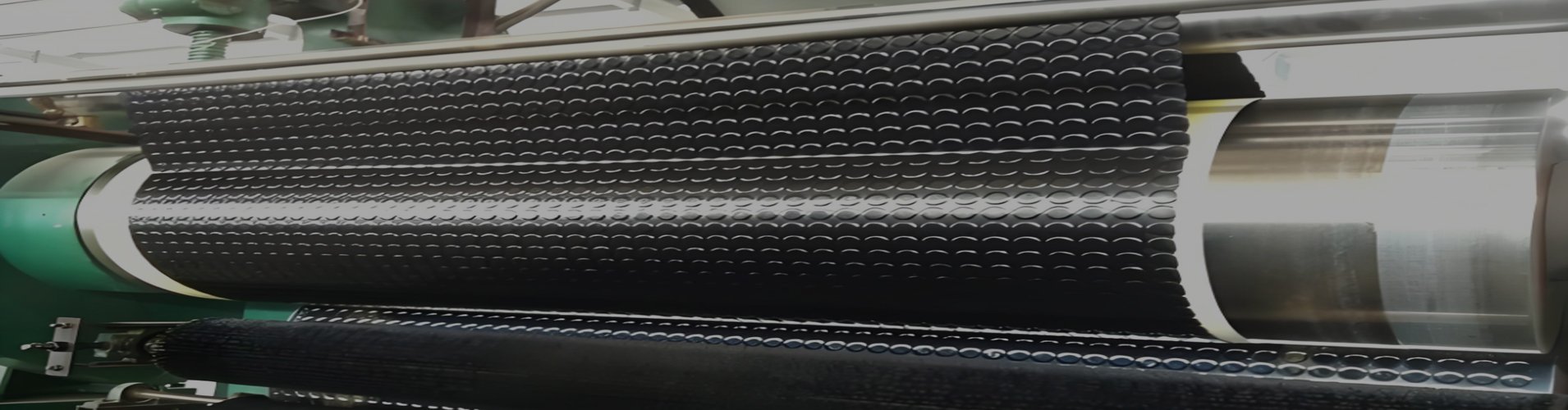

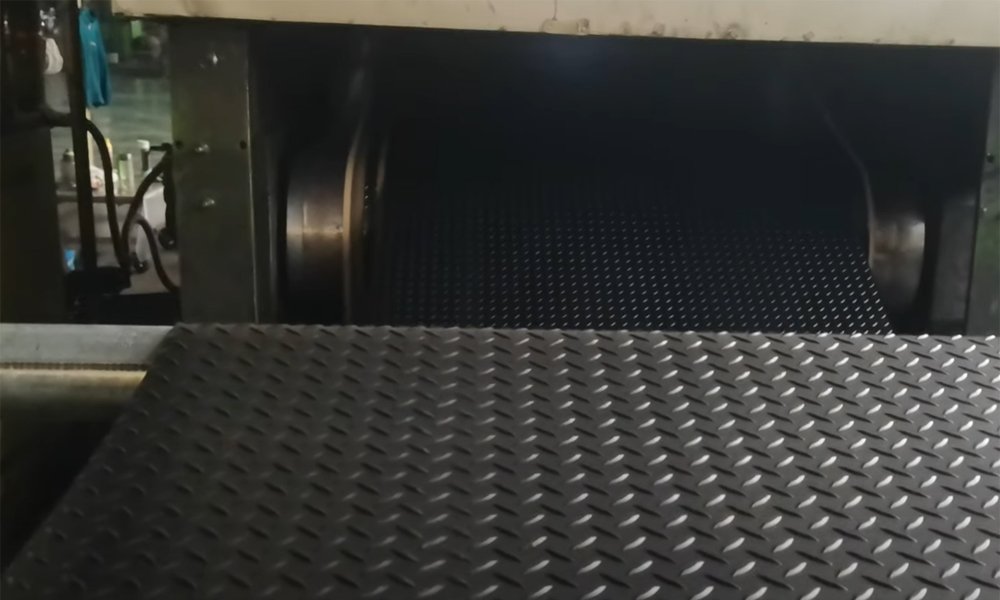

- Calendering and molding mainly refer to the process of molding the mixed rubber sheet through a calender. The process at this time is to keep the raw rubber surface flat and uniform in thickness before vulcanization, so that it can fully control the very important prerequisite preparation before vulcanization.

- The last step of the vulcanization process is to convert raw rubber into vulcanized rubber. Only then can the essential properties of vulcanized rubber be reflected. However, this process involves three very important factors: time, temperature, and pressure. These three points are related to whether the rubber sheet is successfully vulcanized.