AOBO Pulley Lagging Performance

- Methods and materials for roller pulley lagging:

There are two common market lagging methods: rubber lagging and ceramic lagging.

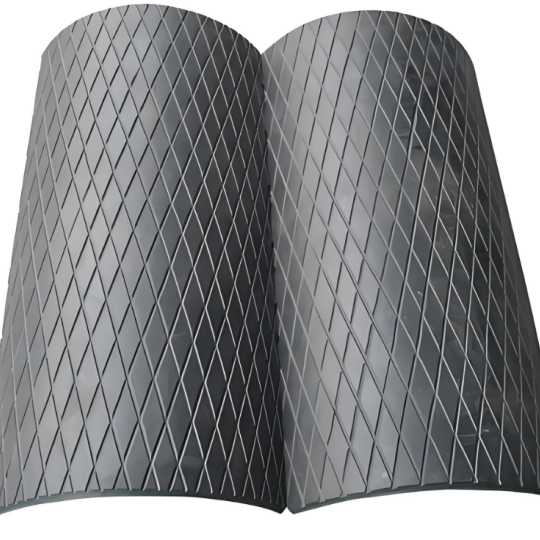

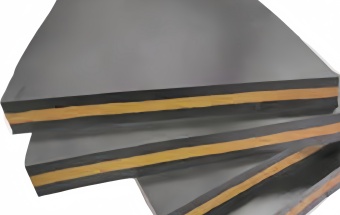

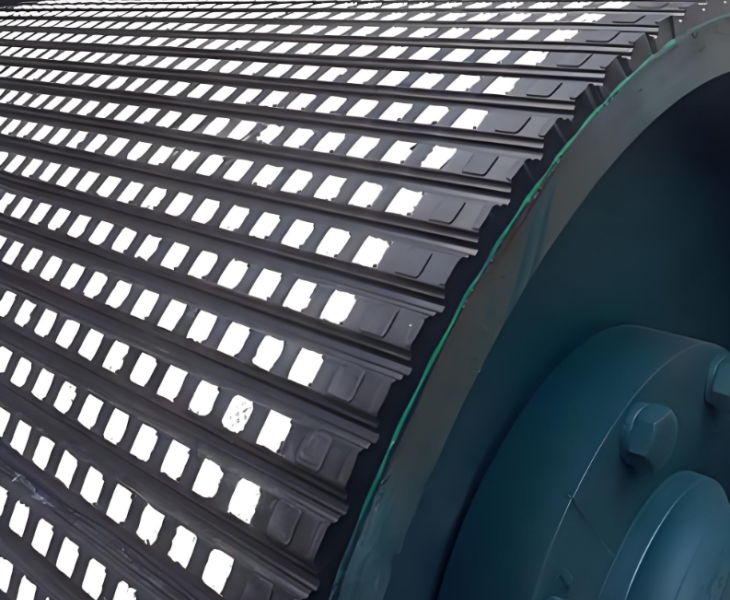

Rubber roller lagging: This is achieved by covering the surface of the roller with a layer of rubber sheet.

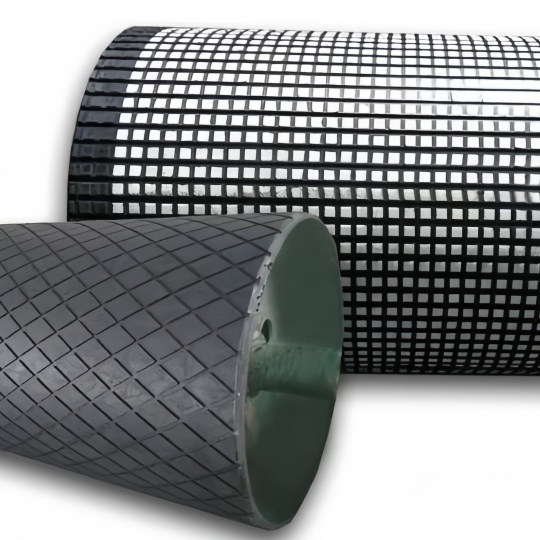

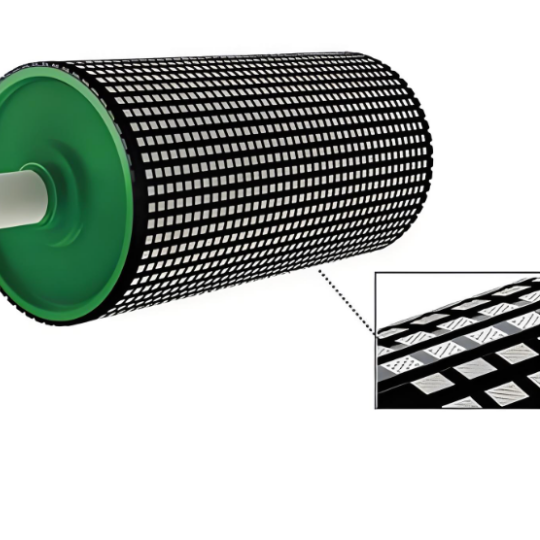

Ceramic rubber sheet roller lagging: Wrap the ceramic rubber sheet on the roller. - High rubber content, excellent wear resistance, tensile and tear resistance

- Pulley lagging is widely used in various industrial fields, such as power plants, coal mines, cement plants, steel, metallurgy, coal, fertilizers, grain depots, ports, and other industries. The rubber lagging treatment can protect the roller and conveyor belt, extend their service life, and improve the enterprise’s production efficiency.

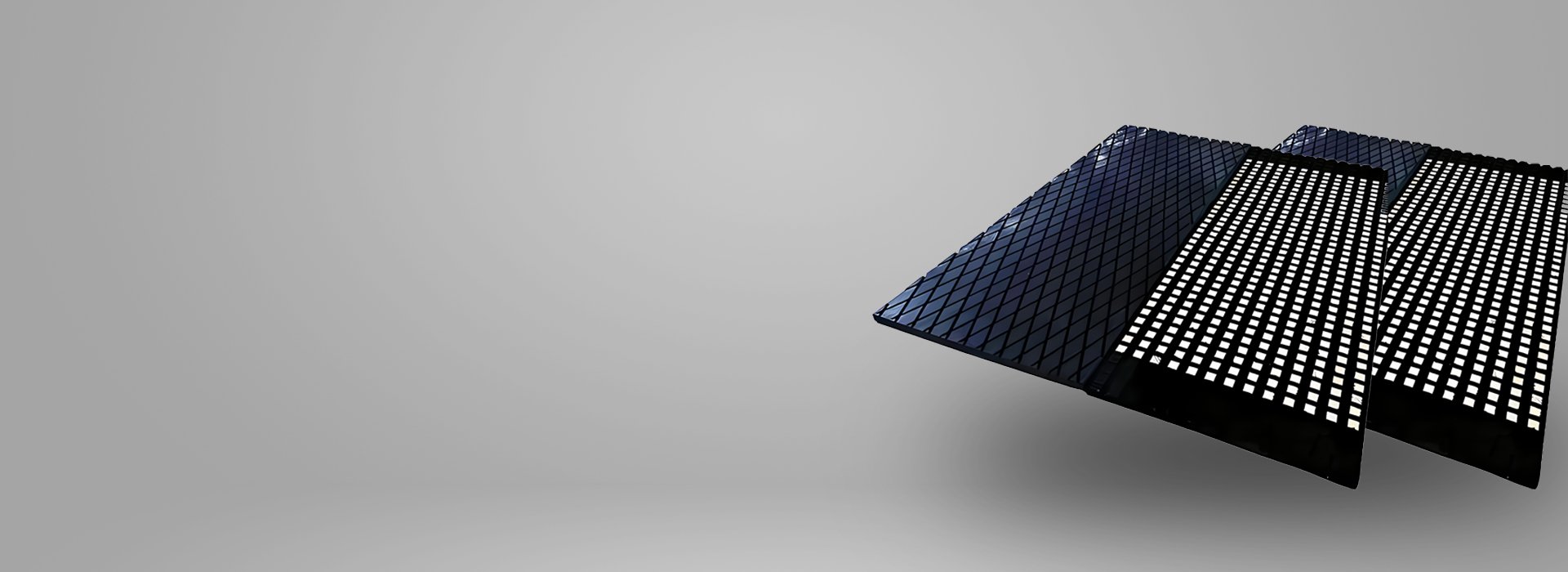

Pulley Lagging

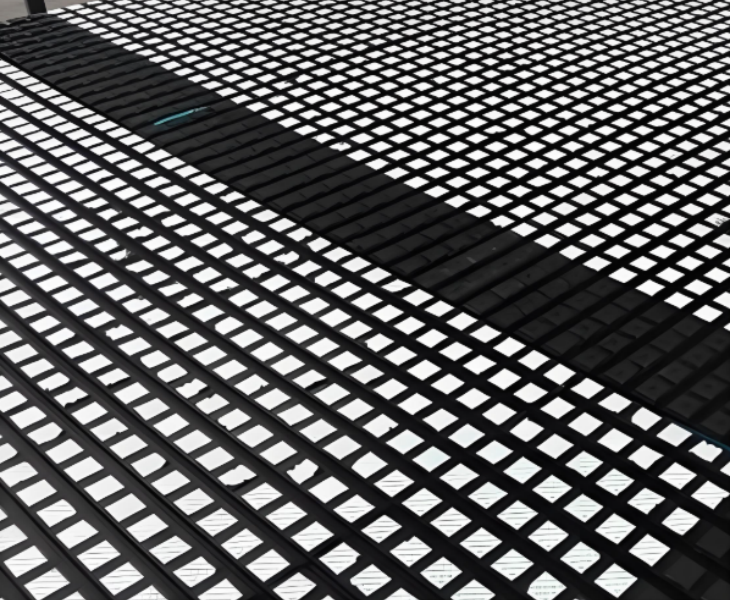

If you need pulley lagging, then AOBO New Material Company will definitely be your first choice. AOBO company has more than 20 years of production experience, and not only that, AOBO New Material company has many types of products from which you can choose. For example, smooth surface pulley lagging, diamond pattern pulley lagging, pulley lagging with adhesive layer, ceramic pulley lagging, etc. AOBO company has many product styles, so our company has an absolute advantage in the market.

AOBO company has its own independent factory. If you buy from AOBO company, these products will be shipped directly from the factory to you, saving you a lot of time to negotiate and communicate continuously, and we can communicate with the factory quickly to make the product achieve the effect you want.

Our engineer team has rich experience in the rubber industry and can teach you how to construct step by step. All AOBO’s products must be tested layer by layer before they are finally issued and sent.

Available Patterns of Pulley Lagging Rubber Sheet

AOBO 2 Types Popular Pulley Lagging Specifications

Rubber roller lagging: Diamond rubber sheet lagging, flat rubber sheet lagging, and ceramic rubber composite sheet all have many different performance indicators.

Based on AOBO’s 20 years of industry experience, we recommend the following five types of roller lagging: three types of rubber roller lagging, two types of ceramic roller lagging ( standard and flame-retardant types).

All are popular brands and specifications in the market, providing you with a professional selection reference.

| Rubber Pulley Lagging | ||||||

| Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | FARS | |

| Tensile Strength: Mpa | 6 Mpa | 8 Mpa | 10 Mpa | 15 Mpa | 20 Mpa | 16 Mpa |

| Hardness: Shore A | 65±5 | 65±5 | 60±5 | 60±5 | 60±5 | 65±5 |

| Density: g/cm3 | 1.35 | 1.35 | 1.25 | 1.2 | 1.1 | 1.4 |

| Elongation | 250% | 300% | 350% | 400% | 500% | 300% |

| Abrasion-resistant | 350mm³/5N | 250mm³/5N | 150mm³/5N | 100mm³/5N | 70mm³/5N | 220mm³/10N |

| Material | SBR Rubber / Natural Rubber | |||||

| Working Temperature | -30~+80℃ | |||||

| Ceramic Pulley Lagging | ||||

| Rubber Typical Values | Standard | Standard | FARS | Reference Standard |

| Tensile Strength: Mpa | 16 | 20 | 16 | GB/T 528-2009 |

| Hardness: Shore A | 63±5 | 63±5 | 63±5 | GB/T 531.1 |

| Elongation: % | 550% | 600% | 550% | GB/T 528-2011 |

| Abrasion Loss: mm³ | 150 | 110 | 150 | GB/T 9867 |

| Visible Flame Duration: s | N/A | N/A | 1 | MT/T 113 |

| Visible Afterglow Duration: s | N/A | N/A | 80 | MT/T 113 |

| Electrical Resistance (Surface):Ω | N/A | N/A | 3 X 104 | MT/T 113 |

| Continous Operating Temperature: ℃ | -40℃ ~ 80℃ | -40℃ ~ 80℃ | -40℃ ~ 80℃ | |

| Peel Strength: Mpa | 13 | 13 | 13 | GB/T 15254 |

| Aging Test | Tensile Strength +1.0% | Tensile Strength +1.0% | Tensile Strength +0.3% | GB/T 3512 |

| Elongation at Break -8.3% | Elongation at Break -8.3% | Elongation at Break -3.3% | ||

The Role & Function of Aobo Pulley Lagging

Pulley lagging increases traction between the belt and pulley, reduces load and wear on the drive, belt, pulley, bearings, and take-up. Lagging in the shop or placed on the system. Proper pulley lagging is an indispensable detail for efficient and economical conveyor operation.

Prevent your conveyor belt from slipping, the pulley roller lagging can provide multiple protections for your equipment:

Enhance friction: The rubber coating (such as diamond pattern, flat surface, or ceramic rubber plate) can increase the friction coefficient, reduce the sliding friction between the belt and the roller, avoid slippage and deviation, and ensure your project’s high-volume and efficient operation.

Protect the roller: Prevent direct wear on the metal surface and extend the service life of the equipment.

Prevent material adhesion: Specially designed grooves and materials can reduce material adhesion and keep the roller clean.

Difference between Rubber Lagging & Ceramic Lagging

Different material properties:

– Rubber lagging: The material is mainly rubber with good elasticity. This elasticity allows the roller to better fit the conveyor belt during conveying, thereby providing stable friction and less damage to the conveyor belt.

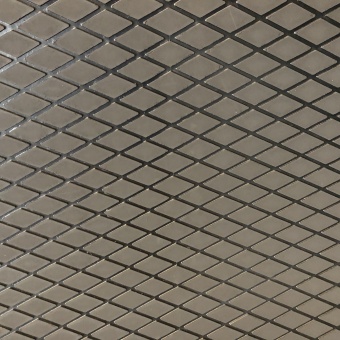

– Ceramic lagging: The main body is ceramic, with high hardness and strong wear resistance. It can effectively resist the wear of sharp and hard materials on the roller, has excellent impact resistance, and is not easily damaged under harsh working conditions.

Different friction performance:

– Rubber lagging: The friction is relatively stable, but in some humid, muddy, or oily environments, the friction may be affected and reduced, causing the conveyor belt to slip.

– Ceramic lagging: The friction is also relatively large, and due to the special structure of the ceramic surface, it can still maintain good anti-slip performance in a humid environment, with good drainage and mud discharge effects and strong self-cleaning ability.

Different applicable scenarios are shown in detail below.

Different Applicable Scenarios of Rubber Lagging & Ceramic Lagging

Rubber lagging is more suitable for conveying scenarios with high friction requirements, relatively soft materials, and a relatively clean and dry working environment, such as conveying materials with small particles and low wear.

Ceramic lagging is widely used in harsh working environments, such as port transportation of coarse ore and large materials. It performs well in conveying materials such as ore and coal with high hardness, large particles, and strong abrasion, and in relatively humid and dusty environments.

In short, pulley lagging technology is widely used in heavy industrial fields.

Aobo Pulley Lagging has Many Advantages

- Strong wear resistance: stable performance under high-load environments.

- High tear resistance: the roller and the rubber sheet have good tear resistance and high adhesion, which can prevent debonding and degumming.

- Can be used in harsh environments: suitable for extremely harsh conditions such as high wear, easy slippage, and wet materials or surrounding environments.

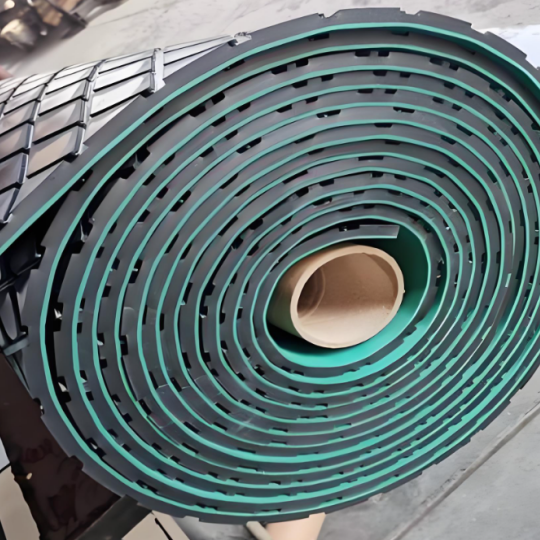

- Very simple construction: It can be constructed on site, is simple to operate, and no large equipment is required.

- While ensuring high cost-effectiveness, AOBO uses our advantages to provide the mining conveying system with the best cost-benefit solution: short-term cost advantage: help you reduce more than 25% of installation costs and reduce 70% of downtime and maintenance expenses; long-term value-added benefits: the service life is 3-5 times longer than that of ordinary rubber.

Super Easy Assembly for AOBO Pulley Lagging

The surface treatment of the pulley equipment includes degreasing, rust removal, phosphating, rust prevention, and other pretreatments, which are all to improve the bonding strength between the rubber and the roller and increase the metal’s anti-oxidation and anti-corrosion capabilities.

The convenience of installation and maintenance is also important, because the downtime cost of mining equipment is high. AOBO has fully considered this, so our pulley lagging has very detailed installation and maintenance instructions for your reference, and teaches you how to use them for a long time.

From selection to use, we help you save worry, time, and cost.

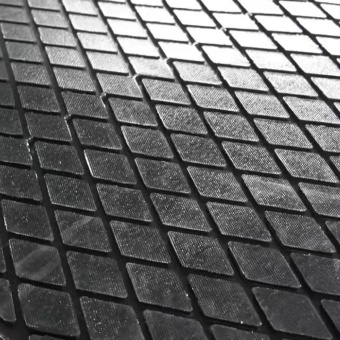

Our company has many styles for you to choose from. But what I recommend to you most is the diamond Rubber Pulley Lagging and Ceramic Pulley Lagging. These two are the most popular models in market.

First you need to tell us your usage scenario, then our professional salesperson will recommend it to you. You can choose according to your needs.

Of course, our company is very happy that you can choose our samples to ensure a pleasant follow-up cooperation.

Related Hot Sell Mining Rubber

Width 2 cm—80 cm. Different materials are available, with flexible customization.

Diamond pattern, excellent anti-slip and wear resistance, with CN-layer.