Is your industrial conveyor belt always slipping, easy to wear and tear, or unreliable operation in a wet environment? In industrial and mining applications, these problems often lead to downtime and higher maintenance costs, and even delay your project. The main reason is not choosing the correct pulley lagging.

For a conveyor belt, the pulley lagging is very important for increasing friction and protecting the pulley from wear, to ensure a longer lifespan for the pulley drum and conveyor belt, and can also increase traction. This guide will show you the details of different pulley lagging types and help you select the correct lagging for your project.

Types of Pulley Lagging for Conveyor Belt Systems

1. Pulley Lagging Types by Surface Pattern

AOBO classifies pulley lagging by surface pattern to help you know the difference in its grip and application.

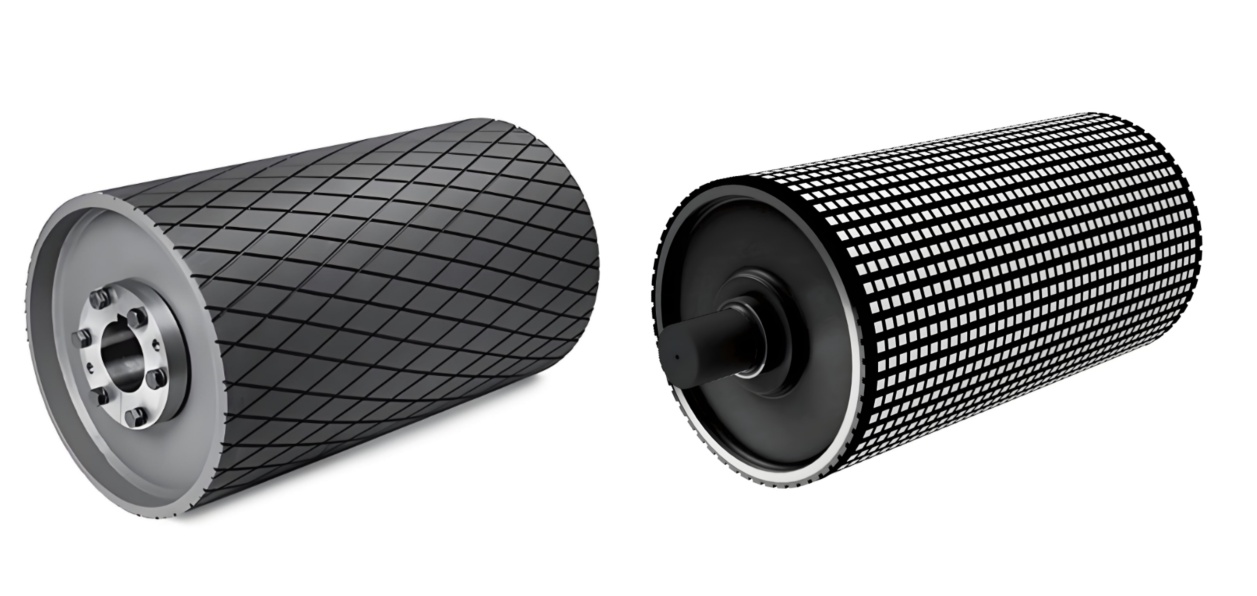

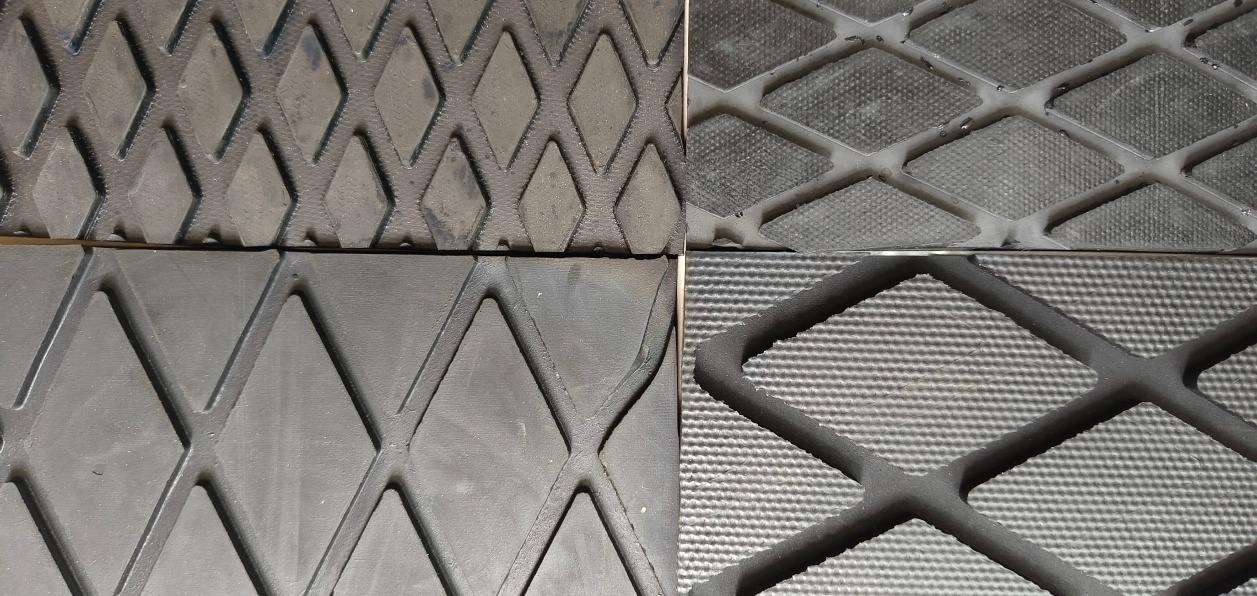

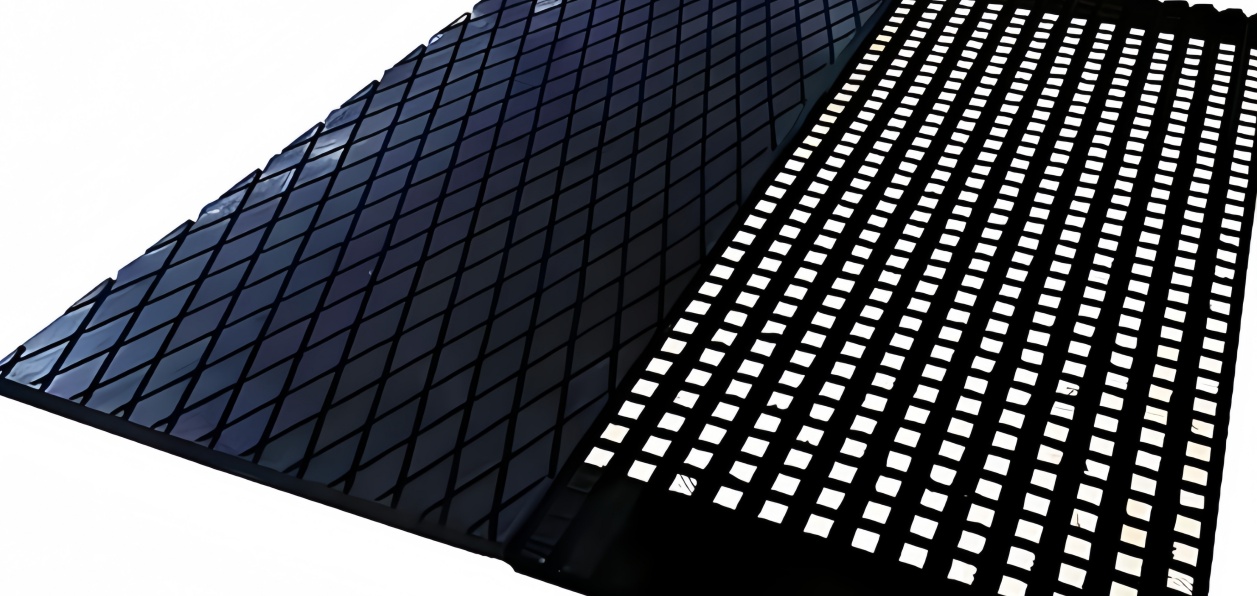

This is the hottest-selling and widely used type of pulley lagging for drive pulleys, with high-grip. The deep diamond groove pattern is designed to increase friction significantly. Also, NR +SBR material is abrasion-resistant, flexible and soft for gripping the belt. The diamond design serves as channels for the removal of water, mud, and fine materials, avoiding buildup, and even in wet or muddy conditions, it can also provide high grip.

AOBO has standard diamond sizes and mini diamond sizes for you to choose. Standard diamond can be used for most general occasions, mini diamond can be used for minor diameter drums or high speed. Wherever drive pulleys, surface-enhancing pulleys, bend rollers, and more are used in a traction project.

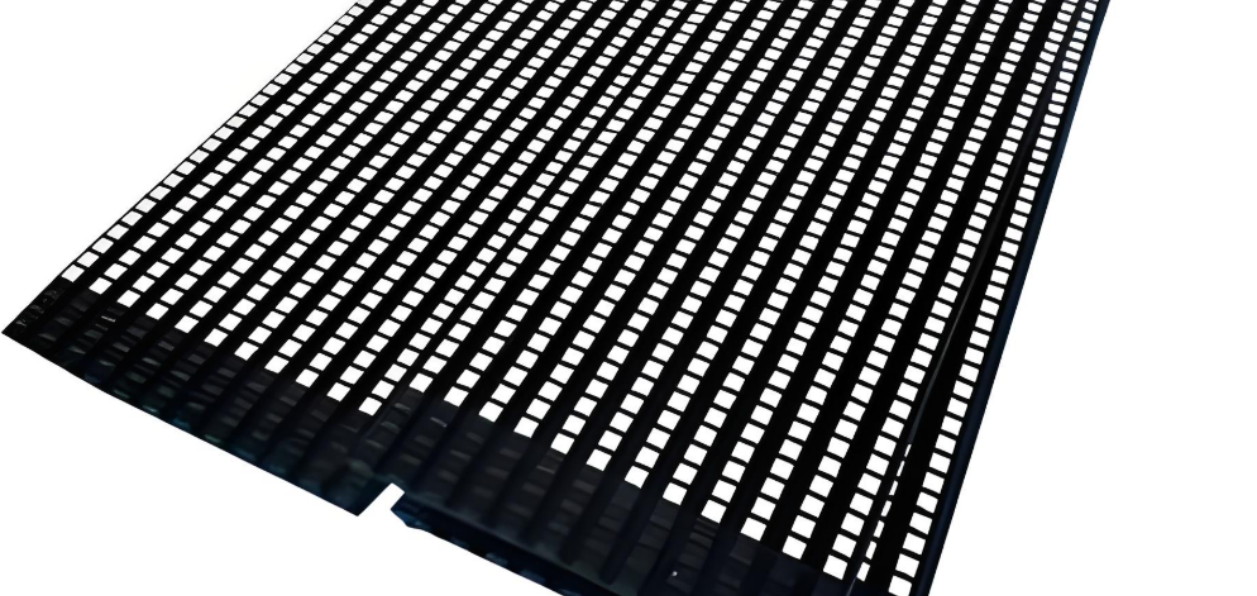

For the most demanding applications, ceramic rubber pulley lagging has ultimate performance. Ceramic blocks are vulcanized into a durable rubber sheet base, the ceramic tile provides a very high coefficient of friction and excellent wear resistance. The rubber sheet matrix is shockproof and ensures a strong bond with the pulley. They work together to provide ultimate traction, especially suitable for harsh environments such as wet and muddy conditions. Wear resistance is 5-8times than ordinary rubber pulley lagging, so it has an ultra-long service life.

In summary, the ceramic lagging is suitable for long-distance & high-tension conveyors, as well as those handling highly abrasive materials (such as iron ore and sharp aggregates) or in extremely wet and muddy conditions where other lagging may fail.

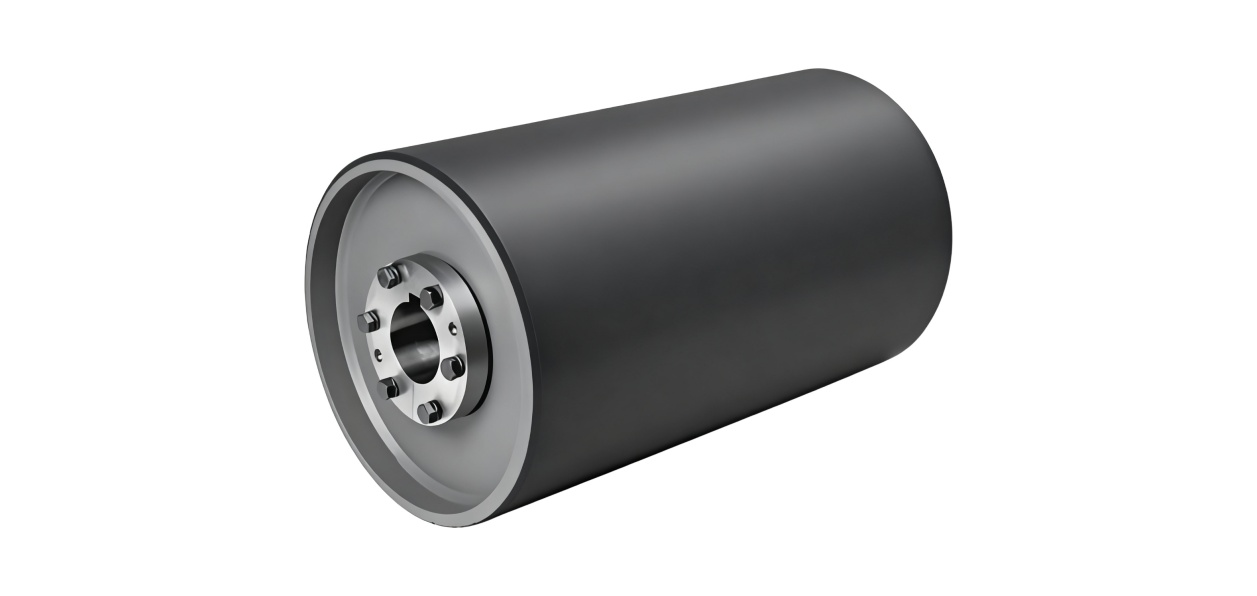

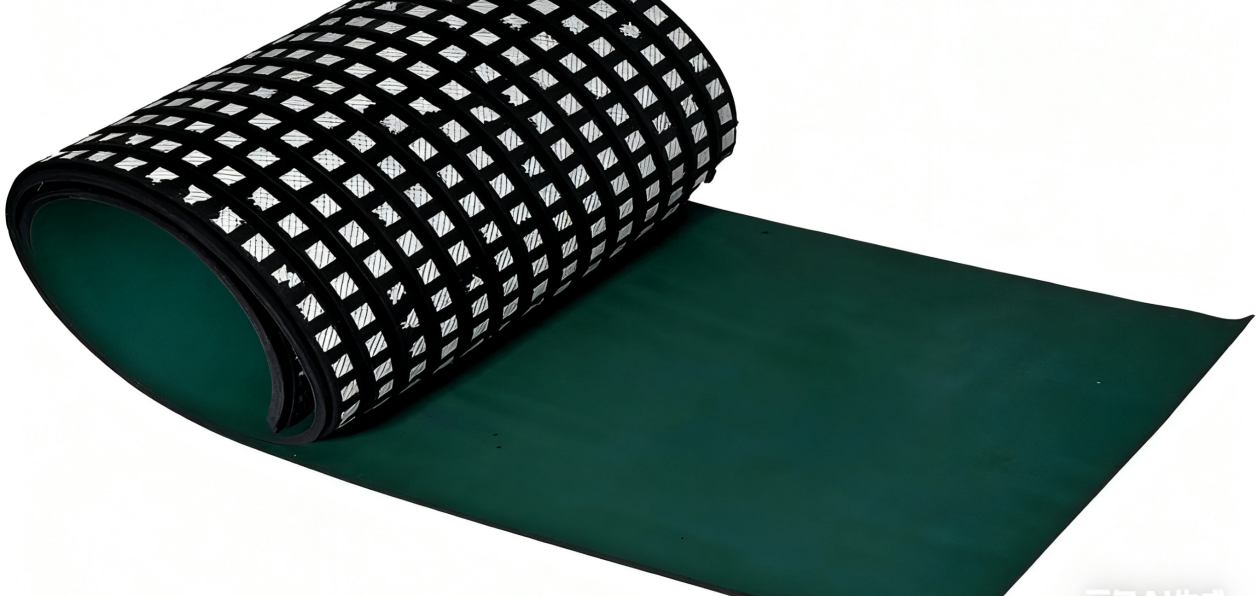

- Flat Rubber Lagging Sheet

Flat type rubber lagging that is basic protection provides a simple protective layer to prevent wear, with minimal added friction. This type is suitable for non-drive pulleys (such as tail pulleys and return rollers), where grip is not a primary concern but wear and corrosion protection is still required.

2. Pulley Lagging Types by Backing

AOBO lagging products are available with or without a CN (chloroprene rubber) backing. The CN layer provides an excellent, ready-to-bond surface for cold-bond applications, simplifying your installation and ensuring an excellent, long-lasting bond to the pulley shell.

3. Pulley Lagging Types by Safety Specification: Standard & FRAS

In addition to standard types, AOBO also offers FRAS (Flame Retardant Antistatic) lagging. This is a key safety requirement in underground mining, particularly coal mines, to prevent fire risks and dissipate static electricity.

How to Choose the Right Pulley Lagging

Below will show you the key factors on the basis of careful analysis of your systems.

- Operating Environment: dry, wet, or muddy? Diamond is suitable in moist conditions, ceramic can in extreme conditions.

- Material Abrasiveness: according to the material you will be conveying, sand, sharp rocks or heavy ore? The more abrasive the material, the more suggest you choose ceramic lagging.

- Pulley Function: Is it a driven pulley (requiring high grip – diamond or ceramic) or a non-driven pulley (requiring only protection – flat surface)?

- Belt Speed and Tension: A high-speed, high-tension system needs a strong grip and durability. Diamond groove or ceramic is suitable for that.

- Pulley Diameter: Ensure the lagging thickness is suitable for your pulley drum diameter.

AOBO pulley lagging rubber sheet suitable for cold bonding, which is easy to install and widely used in on-site applications, this provides flexibility for you across various industries, including mining (like coal, iron ore, copper, gold), quarrying, and bulk material handling etc.

In summary, Flat lagging provides protection, diamond groove lagging offers grip and performance, and ceramic lagging provides ultimate durability for the toughest work. According to your project needs, you can select suitable lagging that maximizes service life, minimizes downtime, and lowers the total cost of ownership. If you’re still not sure, contact AOBO now to help you analyze and find the most suitable one.