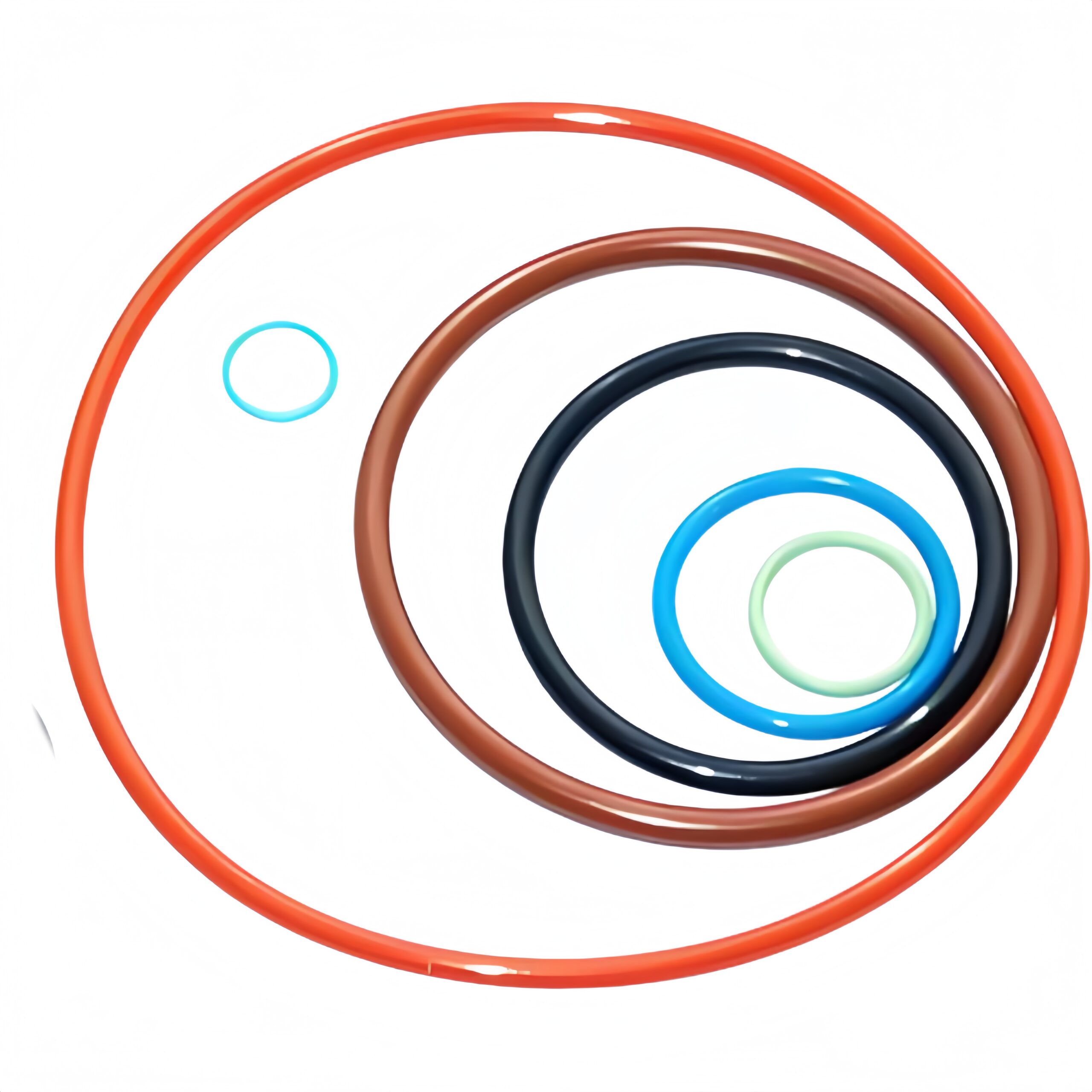

Rubber O-Ring

Rubber O-ring is a rubber sealing ring with a circular cross-section, named after its O-shaped cross-section. Rubber O-rings are usually made of synthetic rubber, have good sealing performance and long service life, and are widely used on various occasions that require sealing.

AOBO – not just a supplier, but also your sealing solution expert! AOBO focuses on providing you with high-quality, multi-specification, full-material rubber O-rings to meet the diverse needs of various industries for seals. We are committed to providing you with one-stop solutions to ensure each product meets the highest standards.

Contact us to start the journey of cooperation!

Materials and Features of AOBO Rubber O-rings

Your different application needs require rubber O-rings of different materials.

At AOBO, we provide you with a variety of synthetic rubber O-rings, including nitrile rubber (NBR), fluoro rubber (FKM), EPDM, silicone, polytetrafluoroethylene (PTFE), chloroprene rubber (CR), hydrogenated nitrile rubber (HNBR), etc. These materials not only have excellent elasticity and wear resistance but also maintain stable sealing performance under extreme environments such as high pressure and high temperature.

Whether you need oil-resistant, corrosion-resistant, high-temperature-resistant, or ozone-resistant solutions, our rubber O-rings can meet your needs. They can effectively prevent gas or liquid leakage, reduce vibration and noise, and ensure that your equipment operates efficiently under various working conditions.

Choose AOBO to tailor the most suitable sealing solution for you!

Why Choose AOBO's Rubber O-rings?

Because AOBO provides you with a full range of O-rings, from standard specifications to customized needs, using high-quality raw materials and advanced technology to ensure that the products have excellent properties such as high-temperature resistance, corrosion resistance, and wear resistance.

With a strong supply chain, we can achieve fast delivery for you and reduce waiting time. Our products comply with international standards such as ISO, FDA, RoHS, etc., and are suitable for high-demand industries. At the same time, they help you reduce costs with high-cost performance. There is also a professional team to provide you with selection guidance and technical support to ensure that you choose the most suitable product.

AOBO – your sealing solution expert, meeting your every need!

Aobo's Rubber O-Ring Manufacturing Process Tailors High-Quality Seals For You

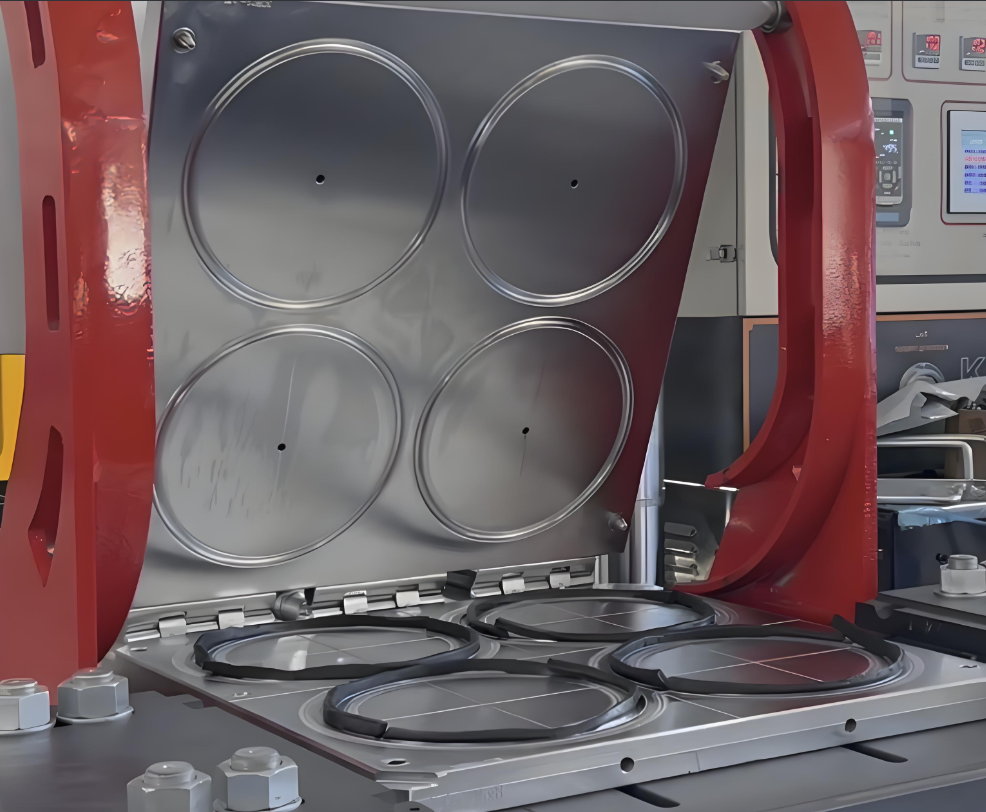

AOBO strictly manufactures according to the shape and size you need to ensure that each O-ring can perfectly match your needs. The manufacturing process includes key steps such as raw material mixing, molding, and vulcanization:

- Raw material mixing: We evenly mix high-quality rubber materials with processing aids and pre-treat them through an internal mixer to ensure that the materials have excellent plasticity and processability, laying a solid foundation for your rubber O-rings.

- Molding: Use precision molds to mold rubber materials to ensure that the size and shape of each O-ring are accurate and correct to meet your application scenarios.

- Vulcanization: Through the vulcanization process, the rubber material is stably molded, giving the O-ring excellent high-temperature resistance, corrosion resistance, and wear resistance, ensuring that it can provide you with reliable sealing effects under various working conditions.

AOBO uses exquisite craftsmanship to create trustworthy rubber O-rings for you!

The sealing principle of the AOBO rubber O-ring is based on extrusion-type sealing. When the O-ring is compressed and installed in the groove, it will undergo elastic deformation and form contact pressure on the sealing contact surface. If this contact pressure is greater than the internal pressure of the sealed medium, no leakage will occur. Otherwise, leakage will occur.

Whether it is a pump, cylinder, connector, or valve, rubber O-rings can provide you with excellent sealing performance. It can be used for static sealing to ensure that the connection between different components is tight and prevents liquid or gas leakage; it can also be used for dynamic sealing, such as the reciprocating motion seal of the piston to ensure smooth operation of the equipment. Due to its simple structure, easy installation, and low cost, rubber O-rings have become one of your most trusted seals in hydraulic engineering.

In your mechanical industrial equipment, rubber O-rings are widely used in static and dynamic sealing of various pumps, valves, and pipelines;

In your automotive industry, it provides reliable sealing protection for key components such as engines, gearboxes, and transmission systems;

In your electronic and industrial equipment field, it ensures efficient sealing and stable operation of equipment such as electronic components and instrumentation.

Rubber O-rings are typically round and vary in thickness. Rubber O-rings are not only suitable for static sealing but also for dynamic sealing, especially in high-pressure applications.

Rubber gaskets are flat seals that sit between two flat surfaces. Gaskets are often circular, however, they can be cut into virtually any shape, including square, triangle, rectangle, or any other complex form. Rubber gaskets are mainly used for static sealing and are suitable for occasions with low pressure and low temperature.