AOBO Rubber Pulley Lagging Performance

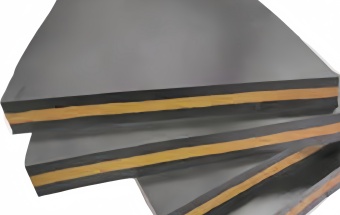

- Material: Natural and Synthetic Rubber

- Superb Wear Resistance: Less than 180mm³/5N (150mm³, 100mm³, 70mm³)

- Color: Black

- Depending on its hardness, specific gravity, bonding layer, mechanical properties, and surface finish, a variety of choices are available.

- The surfaces are available in various profiles like diamond, square, and plain profiles. The back can be made of a cloth-textured bottom, vulcanized adhesive layer, and semi-vulcanized adhesive layer, which is convenient for bonding with cold adhesive.

- Feature: High elasticity and excellent abrasion resistance. Resistance to corrosion, ozone, and adverse weather conditions, temperatures, UV rays, and radiation.

Rubber Pulley Lagging

If you want to buy rubber pulley lagging and are overwhelmed by the choices in the market, then AOBO New material company is definitely your best choice. Because AOBO company has absolutely competitive prices in the market and super good quality. Not only that, we can also listen to your needs very carefully and recommend the most suitable option for you. Normally we have diamond pulley lagging with 4 different design for you choose or smooth pulley lagging.

AOBO company has a chief engineer with 20 years of experience. He has a full and flexible grasp of the various properties of rubber and is very familiar with rubber pulley lagging. Under his leadership,AOBO company is becoming more and more professional in the rubber field, and the help we provide to customers is also very targeted.

AOBO New Material company has a 20,000 square meter factory, so our company has high requirements and high standards for product quality, so that customers will not have any problems after receiving the products. AOBO company attaches great importance to every order, no matter how big or small. This is why our company’s customers can be spread all over the world.

6 Types Popular Rubber Pulley Lagging Specifications

Based on AOBO’s 20 years of industry experience, we suggest these 6 types of rubber pulley lagging, which are hot-selling grades and specifications in the market, to provide you with a professional selection reference.

They have Standard type & FARS type, in different Tensile strength, Density, Elongation, and abrasion resistance.

1. After being combined with cleaning agents, metal treatment agents, and adhesives, it can produce maximum bonding strength;

2. Hardness 60/65±5 shore A, more friendly to conveyor belts;

3. There are different levels of wear resistance, ≤ 110 mm3 is popular, and it provides a service life of >25000 hours under normal working conditions;

4. The CN layer does not need to be polished.

| Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | FARS | |

| Tensile Strength: Mpa | 6 Mpa | 8 Mpa | 10 Mpa | 15 Mpa | 20 Mpa | 16 Mpa |

| Hardness: Shore A | 65±5 | 65±5 | 60±5 | 60±5 | 60±5 | 65±5 |

| Density: g/cm3 | 1.35 | 1.35 | 1.25 | 1.2 | 1.1 | 1.4 |

| Elongation | 250% | 300% | 350% | 400% | 500% | 300% |

| Abrasion-resistant | 350mm³/5N | 250mm³/5N | 150mm³/5N | 100mm³/5N | 70mm³/5N | 220mm³/10N |

| Material | SBR Rubber / Natural Rubber | |||||

| Working Temperature | -30~+80℃ | |||||

Rubber Pulley Lagging Available Size

AOBO provides comprehensive rubber pulley lagging size and customization services for size, covering the hot-selling sizes, and available sizes for your reference.

| Rubber Pulley Lagging | Thickness(mm) | Width(m) | Length(m) |

| Popular Size | 10/12/15/20mm | 2m | 10m |

| Available Size | 10-20mm | 1-2m | Any |

All rubber pulley laggings are strictly implemented: full-size tolerance control following international standards.

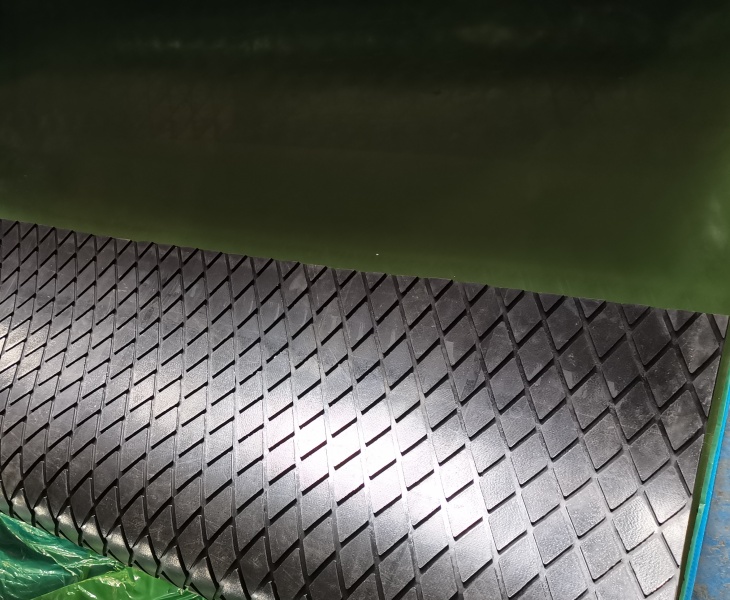

Four Different Diamond Pulley Lagging For You Choose

Diamond pattern pulley rubber lagging has become the market’s first choice due to its excellent anti-slip and wear resistance.

To meet the needs of different working conditions, according to your favorite and your conveyor belt roller size, load and operating environment, AOBO has 4 different diamond pattern sizes for you to choose. perfectly match your project.

Can help you save labor for operating a project also save cost.

The Key Benefits of AOBO Rubber Pulley Lagging

- Available in natural rubber and FRAS-approved rubber

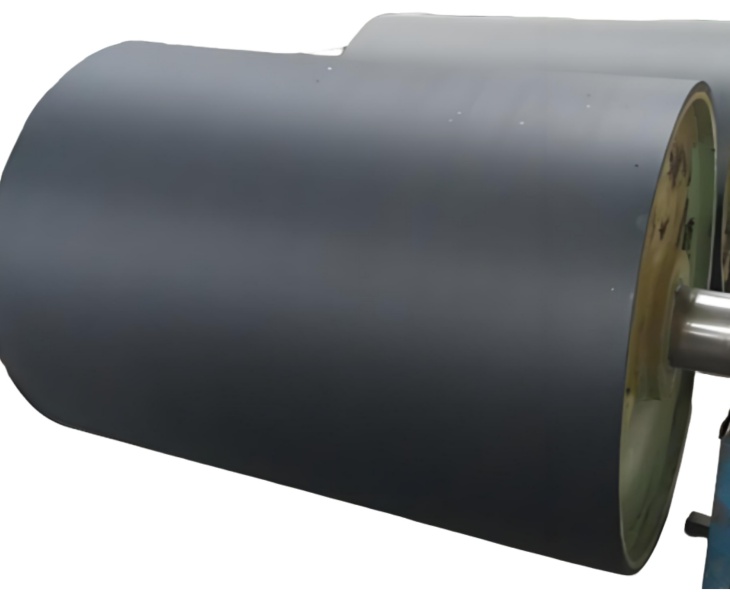

- With CN adhesive layer, semi-vulcanized chloroprene rubber, make sure of high adhesion between rubber and pulley.

- Four different diamond pattern sizes, covering small, medium and heavy-duty rollers.

- Flexible customization: thickness, hardness and rubber type can be customized according to the roller size and use environment.

- High wear-resistant rubber formula is used, and the service life is extended by 50% compared with ordinary rubber lagging

- Prefabricated molding design reduces installation time by 30%, greatly reducing labor costs

- International certification: ISO 9001, MSHA (Mine Safety Certification)

- Our engineering team can provide you with free selection guidance to ensure that you choose the most cost-effective solution

Core Difference Between Diamond Pattern and Flat

Rubber Pulley Lagging mainly has diamond pattern and flat pattern for the surface.

Mainly reflected in the structure and design, performance characteristics, application scenarios, and maintenance costs.

Flat Pattern: has a smooth surface and simple structure, which are suitable for dry and low-speed scenarios (such as grain processing) and have the advantage of low-cost maintenance.

Diamond Pattern: significantly improves friction and drainage through convex pattern design, and has better wear resistance. They are particularly suitable for wet, high-speed or heavy-load conditions (such as mines and ports), but the complex process makes their maintenance costs slightly higher.

The two form complementary choices in wear resistance, friction requirements, and environmental adaptability.

Function of Semi-vulcanized Adhesive CN-Layer

The CN-Layer is on the back of the rubber pulley lagging, it is easy to bond firmly with the cold adhesive, so that the roller and the rubber sheet have good tear resistance and high adhesion, which can prevent debonding and degumming.

Enhanced bonding strength between the rubber and the metal surface of the roller. This chemical bonding method allows the rubber pulley lagging to fit firmly on the roller and makes it not easy to fall off.

Increase the friction between the roller and the conveyor belt, prevent the belt from slipping, and reduce the sliding, thereby protecting the metal surface of the roller from wear and corrosion.

Reduce construction strength: Unnecessary for complex pretreatment and subsequent maintenance work during installation, which is easy to operate, saves construction time and cost.

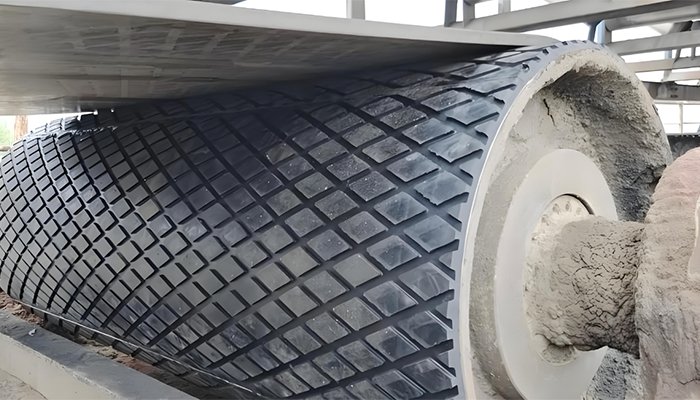

The Role Of Rubber Pulley Lagging

Rubber Pulley Lagging is a blend of natural rubber and synthetic rubbers with high elasticity and excellent abrasion resistance.

Reduce conveyor belt slippage.

Extend the conveyor belt and conveyor pulley life.

Application scenarios: Suitable for roller systems that require high traction for heavy material transportation, as well as inclined and steep slope transportation. The rubber material can increase the friction between it and the conveying system to ensure stable material transportation. Suitable for mining, ports, chemicals, steel, electricity, cement, grain storage, and other industries.

Super Simple Assembly Process

- Preparation: Measure the circumference and width of the roller, and cut the diamond-shaped rubber sheet of appropriate size.

- Surface treatment: Use a grinder to grind the equipment into a rough and rust-free surface, and then clean it with a detergent.

- Apply the treatment agent: First apply the metal treatment agent thinly and evenly on the metal roller, and then apply the adhesive evenly after it is completely dry. Apply it again after it is dry, and apply it on the back of the rubber sheet at the same time.

- Bonding the rubber sheet: When the adhesive is dry to a slightly sticky state, stick the diamond-shaped rubber sheet to the surface of the roller, compact it with a compacting roller, and knock it with a wooden hammer to ensure that there are no bubbles.

Rubber Pulley Lagging Packaging

AOBO offers different packaging ways for rubber pulley lagging, you can choose or we can suggest to you.

Packaging According to Your Requirement.

Ordinary rubber (SBR/NR): -30°C ~ +80°C

High temperature resistant rubber (EPDM): -40°C ~ +120°C (150°C for a short time)

Small area wear: can be repaired on site with rubber repair agent

Large area damage: it is recommended to replace the entire lagging

Choose highly wear-resistant rubber (such as SBR+NR mixed rubber)

Increase the thickness of the rubber lagging (recommended 15-20mm)

Clean the drum regularly to avoid wear from hard particles.

The rollers on the conveyor belt are mostly made of steel, and their working environment is usually harsh. Some materials will corrode the surface of the rollers, and the harsh environment will also accelerate the oxidation process of the steel, thereby reducing the service life of the rollers. Rubber coating the rollers can protect the rollers from erosion and wear by materials, prevent the rollers from rusting, and thus greatly extend the service life of the rollers.

The choice of pulley lagging depends largely on the specific application and conveyor design. To ensure optimal performance, it is important to understand the operating conditions, the wear resistance of the product, the pulley type, the belt operating speed and the tension.

Very durable, you don’t have to worry too much.

Typical lifespan: 3-5 years (normal working conditions), about 2-3 years for heavy working conditions (such as mines);

Key influencing factors: working environment, speed, load weight, material abrasiveness (such as ore vs. grain), cleaning and maintenance frequency.

Related Hot Sell Mining Rubber

Uses wear-resistant ceramic blocks, strong bonding, and extremely long service life.

Width 2 cm—80 cm. Different materials are available, with flexible customization.