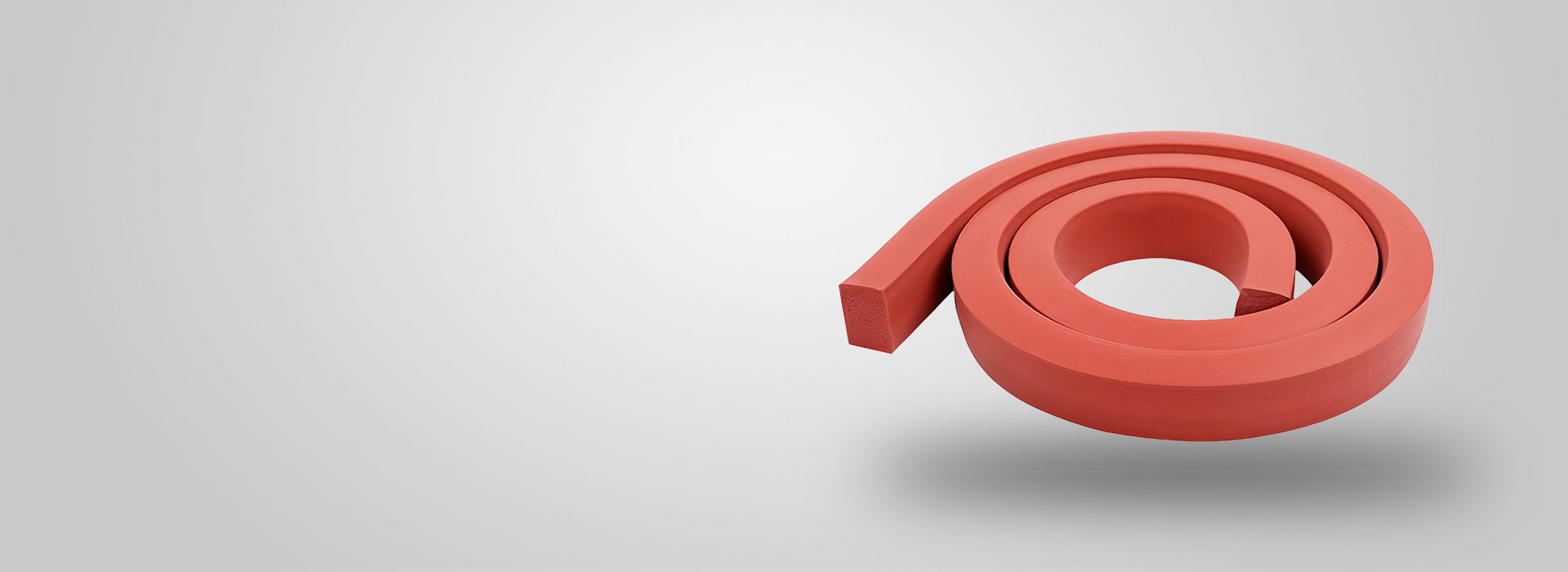

Rubber Sealing

Rubber sealing strips are also called Rubber Strips/ Rubber extrusion strips. It is a strip-shaped or rod-shaped elastic material made of high-quality rubber materials or rubber composite materials, which are used to fill gaps and prevent liquid or gas leakage, and are used primarily for product sealing. Different rubber sealing strips are suitable for different environments and application scenarios. It is widely used in automobiles, machinery, doors, windows, etc., with excellent elasticity, sealing performance, sound insulation, heat insulation, and shock absorption functions.

AOBO focuses on the production of various high-quality rubber sealing strips, providing a variety of material options. Mainly including durable solid sealing strips, and light and soft foam sponge rubber sealing strips, Whether you need to deal with extreme temperatures, strong chemical corrosion, or pursue excellent waterproof and dustproof effects, AOBO can tailor the most suitable sealing products for you.

AOBO insists on innovation as the driving force, strictly controls every production link, ensures that the products have excellent elasticity, weather resistance, and durability, and meet your stringent requirements for high-quality sealing. Let AOBO be your most reliable partner and work together to create an impeccable sealing solution!

How To Test The Performance Of Aobo's Rubber Sealings You Need?

We provide you with comprehensive performance testing services, including:

- Heat resistance test: Through high and low-temperature cycle tests, ensure the stability of seals at extreme temperatures to meet your temperature resistance needs.

- Chemical resistance test: Test the contact performance of seals with oils, acids alkalis, and other chemicals to ensure their corrosion resistance in your use environment.

- Aging test: Conduct UV and ozone aging tests to evaluate the durability of seals and provide you with long-term use guarantees.

- Compression deformation test: Evaluate the elastic recovery ability of seals to ensure that they always maintain excellent sealing effects under pressure.

With professional testing services, we provide you with high-performance and high-reliability rubber seals to meet your diverse needs!

Aobo Provides Professional Solutions For Your Rubber Sealing Needs

Our sealing strips are mainly divided into two categories: solid rubber sealing strips and sponge rubber sealing strips, which can fully meet your diverse needs:

- Solid rubber sealing strips

Made of pure rubber, without skeleton or reinforcement materials, with excellent elasticity and resilience, can effectively fill gaps and prevent gas and liquid leakage.

Material: Provide you with high-performance material options that are oil-resistant, heat-resistant, aging-resistant, low-temperature-resistant, and chemical-resistant, such as FKM fluororubber, NBR nitrile rubber, silicone, EPDM, etc.

- Sponge rubber sealing strips

Made of sponge rubber, it is soft and light, with excellent elasticity, can absorb impact, and provides you with excellent cushioning, sound insulation, and shock absorption effects.

Material: Select materials that are resistant to aging, low temperature, water vapor, and chemical corrosion, such as EPDM, to ensure long-term performance.

Aobo Rubber Sealings Variety Of Applications

Solid rubber sealing strips application: Widely used in your automobiles, mechanical equipment, and other fields to ensure that every seal is reliable and durable.

Sponge rubber sealing strips application: Suitable for your car, machinery, doors and windows, and other scenes, providing multiple functions such as dustproof, insect-proof, waterproof, fixation, sound insulation, shock absorption, etc., to fully protect your equipment and environment.

Yes, AOBO provides comprehensive customization services for you, including:

Material customization: You can choose from EPDM, NBR, silicone, fluoro rubber, and other materials.

Size and shape: Support different lengths, widths, and thicknesses, as well as solid, hollow, and special shapes (such as D-shaped, P-shaped, E-shaped, etc.) can be customized.

Hardness: The rubber sealing hardness can be adjusted according to needs (usually 30-90 Shore A).

Packaging customization: Provide roll packaging, reel packaging, or customized packaging according to your needs.

Our products comply with international environmental standards (such as RoHS, and REACH), and some materials (such as EPDM and silicone) can be recycled to reduce the impact on the environment.

We provide rubber seals of various materials to meet different application requirements:

- EPDM: Excellent weather resistance, water resistance, acid, and alkali resistance, but not oil resistance. Temperature resistance -50°C to 150°C. Suitable for outdoor and high-temperature environments, UV resistance, and aging resistance.

- NBR nitrile rubber: Excellent oil resistance, suitable for environments in contact with fuel and lubricating oil. Temperature resistance -40°C to 120°C. Suitable for scenes in contact with oil such as automobiles and industrial equipment.

- Silicone: High-temperature resistance (-60°C to 250°C) and weak acid and alkali resistance, but not strong acid and oil resistance. Non-toxic and odorless, suitable for food and medical industries.

FKM fluororubber: Resistant to chemical corrosion (strong acid, strong alkali, and various organic solvents.) and high temperature, temperature resistance -20°C to 200°C (short-term up to 250°C) suitable for extreme environments such as chemical equipment.

Natural rubber sealing: good elasticity, suitable for general sealing needs, and low cost.