AOBO Rubber Sheet Performance

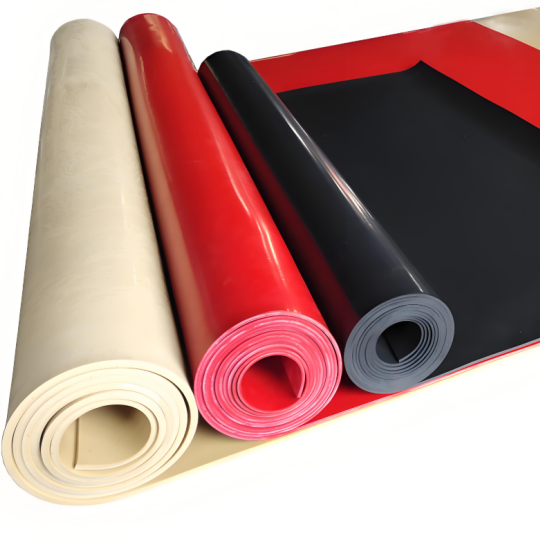

- Conventional industrial rubber sheets, such as SBR, CR, EPDM, NBR, NR

- High-end rubber sheets such as IIR, HNBR, FKM, FMVQ, Sponge, etc.

- Common performance indicators: Tensile strength, hardness, elongation, specific gravity, abrasion, temperature resistance, etc.

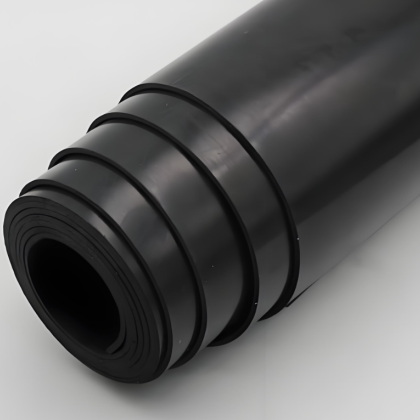

- Surface: double-sided smooth, double-sided cloth texture, one side smooth and one side cloth texture

- Multi-layer cloth and different types of cloth can be added

- Classification: industrial rubber sheet, insulating rubber sheet, anti-static rubber sheet, food-grade rubber sheet, etc.

AOBO Rubber Sheet

Rubber sheets are a versatile solution that is widely used in different industries due to their durability, flexibility and adaptability.

AOBO has rich experience in the production and export of rubber sheets, using high-quality raw materials and advanced technology to ensure stable product performance and high cost performance.

AOBO supports customized production. Whether it is the thickness, hardness or color of the rubber sheet, we can meet your unique needs.

AOBO has strong production capacity, can deliver quickly, and supports global transportation to ensure that you receive the goods on time. The rubber sheets exported by AOBO have passed multiple international certifications, and the quality is guaranteed, which guarantees the safe and long-term development of your business. If you are looking for a rubber sheet supplier, please feel free to let us know.

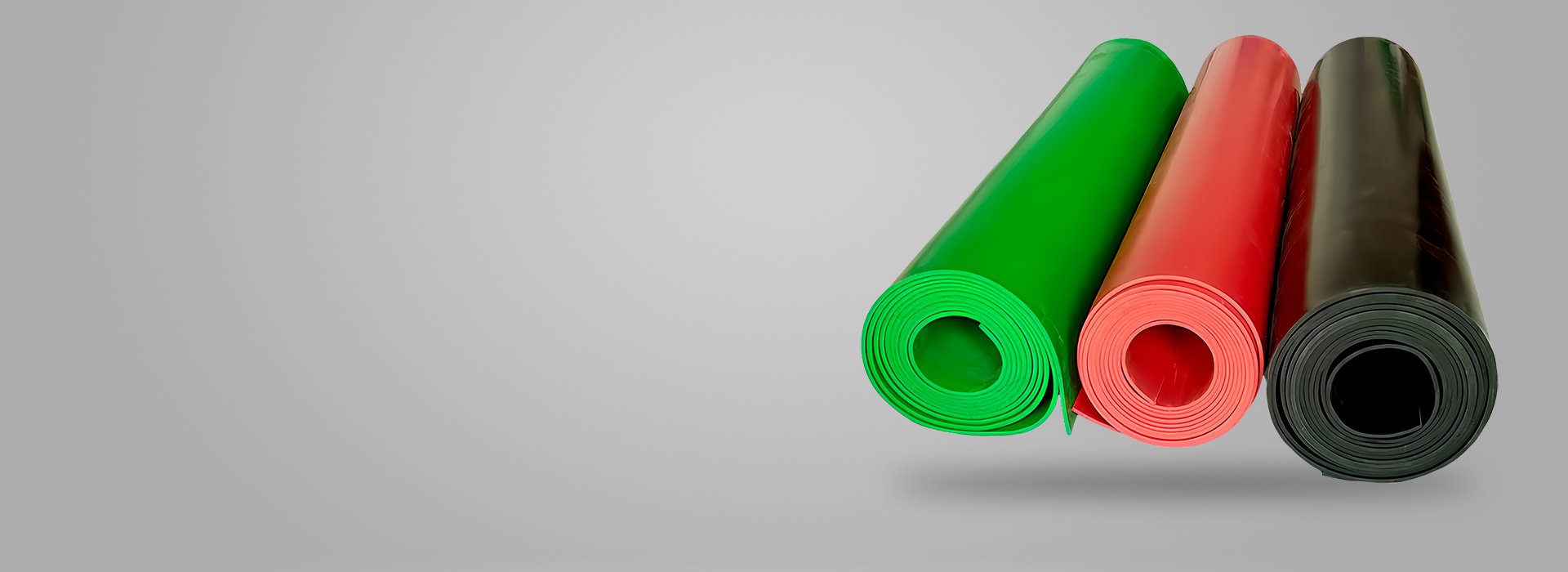

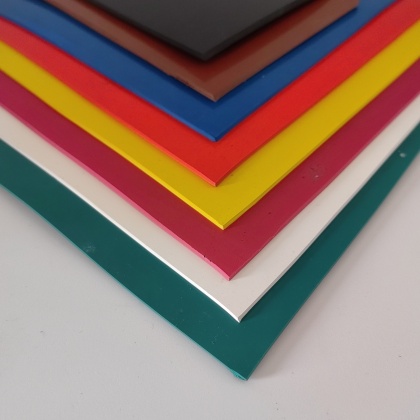

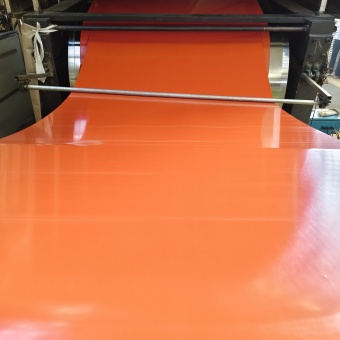

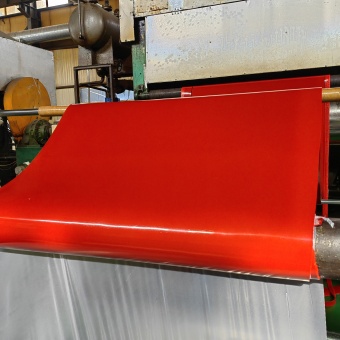

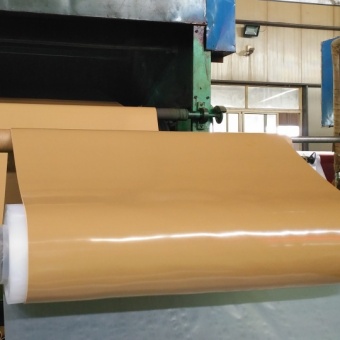

AOBO Colored Rubber Sheets

The different colors of rubber sheets are used not only for aesthetics but also to distinguish their uses, performance, and applicable scenarios.

Black rubber sheet: the most common, mainly used in industrial fields, such as oil resistance, acid and alkali resistance, wear resistance, insulation, and other scenarios.

Green rubber sheet: usually anti-static, used in electronics factories, laboratories, etc.

Blue rubber sheet: common in industrial environments that are acid and alkali resistant, and chemically resistant

Gray rubber sheet: professional insulation, generally used in power plants or general industrial buffering, shock absorption, or sealing

Bright colors rubber sheet, such as red, are used for safety signs or high-traffic areas.

Special color customization can be provided to meet the needs of different industries.

AOBO Provides You with a Variety of Rubber Sheet Materials to Choose from

As an experienced and professional rubber sheet manufacturer, AOBO can provide you with rubber sheets of different materials according to your needs. Not only industrial rubber sheets, such as SBR, CR, EPDM, NBR, NR, HNBR, FKM, FMVQ… also have special rubber sheets like sponge rubber sheet, insulation rubber sheet, insertion rubber sheet… AOBO provides you with a one-stop service.

Each type of rubber sheet has its own excellent performance.

| SBR | Styrene-Butadiene Rubber | high wear resistance, low cost suitable for ordinary industrial rubber sheets. |

| CR | Chloroprene Rubber | acid and alkali resistant, weather resistant, flame retardant commonly used in seals and protective pads. |

| EPDM | Ethylene Propylene Diene Monomer Rubber | ozone resistant, aging resistant suitable for outdoor and automotive seals. |

| NBR | Nitrile Rubber | excellent oil resistance widely used in oil pipes, oil seals and oil-resistant rubber pads. |

| FKM | Fluoro Rubber | high temperature resistant (275°C+), chemical corrosion resistant used for aerospace and chemical seals. |

| SILICONE | Silicone Rubber | high and low temperature resistant (-60°C~230°C), non-toxic suitable for food grade and medical supplies. |

| IIR | Butyl Rubber | excellent air tightness used for anti-corrosion linings, tire inner tubes and chemical products. |

| FVMQ | Fluorosilicone Rubber | both oil resistant and high and low temperature resistant suitable for extreme environment seals. |

| NR | Natural Rubber | high elasticity, tear resistance suitable for wear-resistant linings, mining protection, bullet plates, etc. |

| HNBR | Hydrogenated Nitrile Rubber | oil resistant + high temperature resistant (150°C) used in automotive fuel systems and industrial seals |

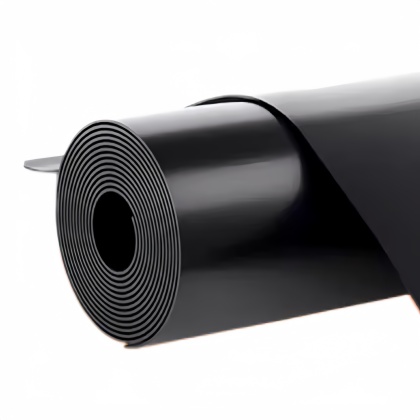

SBR Rubber Sheet: The most economical. Different Tensile strengths or hardnesses, colors are available, can be with different fabrics inserted, or with fabric impression.

Silicone Rubber Sheet: Different Grades Available: Standard Silicone/Food Grade Silicone/ Gas Phase Silicone/ Fire resistant Silicone/ Laminating machine Silicone/ Laminator Silicone.

NBR Rubber Sheet: Ultra-thin available, Extra-width size available. Different Grades Available: Commercial Grade NBR/SBR, Pure NBR, High Grade Pure NBR…

CR Rubber Sheet: Also called Neoprene Rubber Sheet. Ultra-thin, extra-wide size, or different colors are available. Different Grades Available: Commercial Grade CR/SBR, Pure CR, High Grade Pure CR…

FKM Rubber Sheet: Different Commercial Grade, High Strength Grade, Pure FKM Grade, Peroxy FKM Grade available. The FKM content can reach 69%-70%.

EPDM Rubber Sheet: Ultra-thin available, Extra-width Size Available. Different Grades Available: Commercial Grade EPDM/SBR, Pure EPDM, High Grade Pure EPDM…

NR Rubber Sheet: Have different types: popular ones (Conventional NR, Pure NR, High wear resistance NR, High tear resistance & high wear resistance & high rebound NR).

IIR Rubber Sheet: The core use is anti-corrosion rubber lining; a double-sided cloth-textured surface is recommended. It can be unvulcanized, pre-vulcanized, or vulcanized.

FVMQ Rubber Sheet: Combines the high performance of silicone and the fluororubber. Fluorosilicone raw film (unvulcanized/compound) available.

HNBR Rubber Sheet: The highlight is heat oil resistance, suitable for hot oil resistance of 140-150 ℃. Excellent long-term temperature resistance.

What Can Rubber Sheets Do For You?

Different industrial environments place unique demands on rubber materials. At AOBO, we offer professionally graded rubber sheets, each designed to solve a specific requirement:

- Dealing with high-temperature environments? → Heat-resistant rubber sheets

- Exposure to strong sunlight? → UV-resistant rubber sheets

- Undergoing constant friction and wear? → Abrasion-resistant rubber sheets

- Contact with oil and chemicals? → Oil-resistant rubber sheets

- Safety first, need fire protection? → Flame-retardant rubber sheets

- Reduce noise pollution? → Sound-proof rubber sheets

- Absorb shock and vibration? → Shockproof rubber sheets

- Resist acid corrosion? → Acid-resistant rubber sheets

- Need a safe, non-slip, and durable rubber mat? → rubber mat flooring

Contact AOBO to help you accurately solve all your questions.

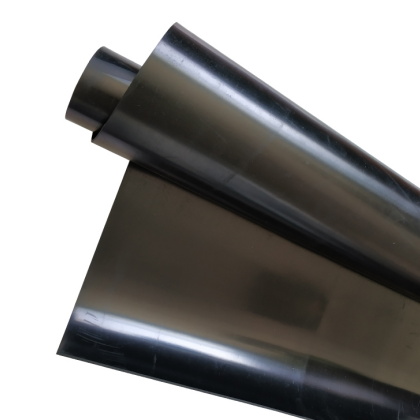

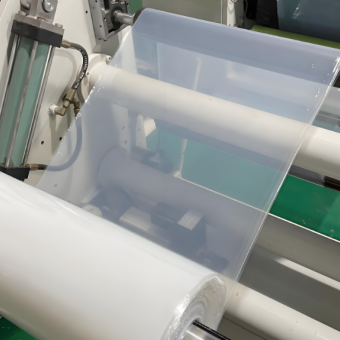

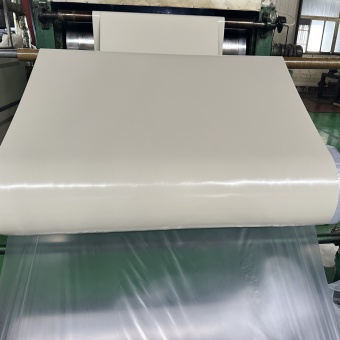

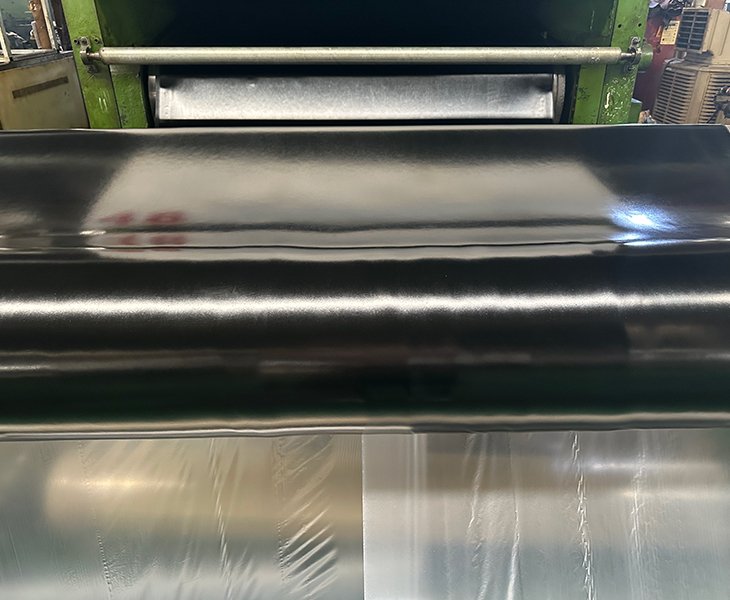

AOBO Can Provide You with Ultra-Thin and Ultra-Wide Rubber Sheets

Most suppliers limit the width of rubber sheets to less than two meters. AOBO has launched ultra-wide rubber sheets of 2~3 meters to meet your more diverse needs.

In addition, AOBO can also produce ultra-thin rubber sheets with a thickness of 0.4-1mm. Ultra-thin rubber sheets have significant advantages in certain specific application scenarios, such as occasions that need to save space or reduce weight.

AOBO will always do its best to meet your needs.

AOBO Professional Rubber Sheet Perfect Fit for Your Industry

Industrial rubber sheets have the above features, so they can be directly applied to your field:

- Wear-resistant and impact-resistant rubber linings in mines extend equipment life ➔ save maintenance costs.

- Comfortable cow rubber mats on farms improve animal health ➔ optimize breeding benefits.

- Various rubber sealing sheets with oil and chemical resistance in industry ➔ ensure production safety and continuity.

- Durable rubber roofing sheets for buildings provide long-term protection ➔ reduce renovation expenses.

- Non-slip and wear-resistant rubber flooring for warehouses/factories/garages improves safety & durability ➔ reduces the risk of slipping, and improves work efficiency.

Choosing AOBO is not just choosing a rubber sheet, but also choosing a reliable, durable, and cost-effective solution for your specific application scenario.

AOBO Provides You with Factory Prices for Rubber Sheets

AOBO has more than 20 years of experience in rubber production and export. From the establishment of the company to now, AOBO has continuously innovated its equipment and technical personnel. At present, AOBO adopts large-scale production, strict cost control, and can provide customers with more favorable prices.

As a factory direct supply, we can not only guarantee price advantages, but also flexibly customize to meet your special needs.

Choosing AOBO, you can improve your local competitiveness in all aspects.

Comparison of Rubber Temperature Resistant Ranges

This table intuitively shows the temperature resistance of different rubber sheets (such as butyl rubber, silicone, nitrile rubber, etc.), allowing you to clearly understand the applicable temperature range of each material. Through clear comparative data, it provides you with a professional material selection basis to ensure that the product can still perform stably in extreme temperature environments.

Different Rubber Sheet Materials: SBR, CR, EPDM, NBR, FKM, NR, Silicone, CSM, Butyl, FVMQ, HNBR

The data is based on ASTM standard testing and is authentic and reliable.

However, in special cases, different formulas can be added to meet your more specific practical application scenarios. Please contact AOBO, and our engineers can provide more detailed material selection suggestions.

Chemical Adaptability of Various Rubber Materials

AOBO rubber sheet material chemical compatibility comparison table: lists in detail the key properties of NBR, EPDM, FKM, Butyl, and other materials, such as acid resistance, alkali resistance, oil resistance, etc., to help you quickly match the rubber material suitable for the working conditions.

Different Rubber Sheet Materials: CR, SBR, EPDM, NBR, Butyl, Hypalon, VMQ, HNBR, FKM, FFKM, FVMQ, FEPM, Silicone

Different Chemical Adaptability: Resistant to Acids, Oils, Steam, Ethers, Alcohols, Alkali, Ketones, Amines, Aldehydes.

Divided into 4 Grades: Excellent, Good, Fair, Poor

All data are verified by ASTM standard tests, providing a scientific basis for material selection for your equipment sealing and pipeline applications.

Note: The above data are general reference values. The actual chemical resistance may vary due to different acids (such as dilute sulfuric acid, hydrochloric acid, etc.), alkalis, oils, and their concentrations. If you need precise selection, please contact the AOBO technical team for professional support.

AOBO Rubber Sheet Packaging

AOBO offers different packaging ways for Rubber Sheet, you can choose or we can suggest to you.

Packaging According to Your Requirement.

Natural rubber is formed from the latex harvested from rubber trees, while synthetic rubber is extracted from petroleum and processed and synthesized. Synthetic rubber has different functions to make up for the shortcomings of natural rubber. Synthetic rubber has a wide range of uses, and all rubbers except natural rubber are synthetic rubbers.

EPDM rubber is the best anti-aging rubber at present.

Yes,we can.You can send us your designed logo information to us,we can vulcanize the logo on the rubber sheet or print on the package bags.

Related Hot Sell Rubber Sheets

Multifunctional safety flooring, with anti-slip surface, shock absorption, wear resistance, and both practical and economical.

Non-slip walking channel mat & Comfortable bed cow mattress. Comprehensively improve the health of dairy cows.

EPDM is an ideal choice for outdoor sealing and protection applications. Different content and grades available.

Called Rubber King. High-quality, versatile, and high-performance rubber sheet material that is widely recognized.