AOBO Rubber Strips Performance

- 2 cm- 80 cm width full-size coverage

- Various material options: SBR, NBR, EPDM, CR, natural rubber, super wear-resistant rubber, sandwich rubber sheet, etc. The specific materials can be selected according to customer needs to meet different oil resistance, high temperature resistance, or corrosion resistance.

- High strength adaptation: tensile strength 3-24MPa optional

- Precise cutting process: professional machine cutting, smooth edges without burrs

- Free samples are available

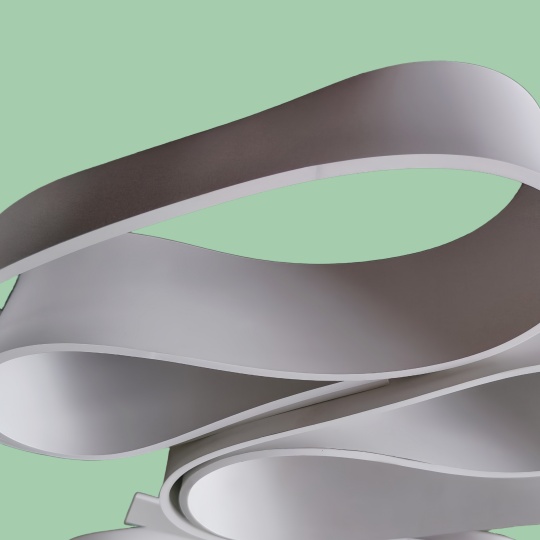

AOBO Rubber Strips

Rubber Strips are made by cutting a whole piece of rubber sheet into strips of a specific width. They have both the elasticity of rubber and the ease of installation of strip structures. They are mainly used in three functional scenarios: sealing, shock absorption, and protection.

AOBO strip rubber sheets can also be customized according to your specific requirements, including adjustments in thickness, width, color, surface treatment, etc. to meet specific usage requirements. Whether it is industrial sealing or shock absorption or anti-skid, our rubber strips can provide you with efficient and durable solutions.

Welcome to contact us for exclusive customization services and preferential quotes!

Popular Types Rubber Strips Specifications

With 20 years of professional experience in the rubber field, AOBO has carefully selected a series of high-performance rubber strip products that are widely recognized in the market, covering a variety of high-quality materials such as SBR, NBR, EPDM, etc.

Each product has been strictly tested and marked with key performance parameters (such as tensile strength, hardness, material content, etc.). These types really hot sell in the world market, providing you with a professional and reliable selection reference.

We also support a full range of customized services. If you want to change the material, strength, hardness, and other properties, please contact AOBO for specific details.

AOBO Rubber Strips Available Size

AOBO provides comprehensive Rubber Strips size and customization services for size, covering the hot-selling sizes, and available sizes for your reference.

| Thickness | Width | Length | |

| Popular Size | 2-30mm | 10-50cm | 10-20m |

| Available Size | 1-50mm | 2-80cm | 1-30m |

Why Choose AOBO Rubber Strips

- AOBO provides customized production and tries its best to meet your requirements.

- Different materials, widths, and tensile strengths are available

- AOBO provides customized packaging, which is beautiful and can effectively protect the rubber strips

- Easy to install

- AOBO provides you with perfect after-sales service

- The same quality has a better price, the same price has better service

- The edge processing needs to ensure that the cut is smooth and burr-free

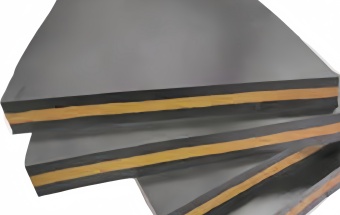

Materials of Rubber Strips Directly Affect the Performance

- SBR is low-cost and widely used in various industries. Rubber strips are usually made of this material.

- NR has good self-healing properties, wear resistance, and high strength. Red and orange are generally used as the first choice for rubber strips. It is the most cost-effective product.

- Nitrile rubber has strong oil resistance and is mostly used for automobile oil pipes and fuel tank seals.

- EPDM rubber has outstanding aging resistance and is suitable for outdoor equipment protection strips.

Application Scenarios of AOBO Rubber Strips

The rubber material itself has the characteristics of good elasticity, wear resistance, and anti-slip. After being cut into strips, it is easier to install and use. It is widely used in machinery manufacturing, construction engineering, automobile maintenance and other fields.

Rubber strips are widely used to make wear-resistant conveyor belt ribs in mines, equipment gaskets, etc., which play a sealing role, protect the equipment, and increase the convenience of construction.

Rubber strips can also be used in shooting ranges.

AOBO rubber strips can also be used for: Snow shovel, sealing rings, sealing strips, gaskets, and other occasions.

Comparison of Rubber Temperature Resistant Ranges

This table clearly compares the temperature resistance range of various rubber sheet materials (such as Silicone, NBR, EPDM, FKM, etc.), helping you quickly understand the applicable temperature environment of different materials. Through intuitive data comparison, it can provide professional reference for your product material selection and ensure that excellent performance is maintained under high or low temperature conditions.

Different Rubber Sheet Materials: SBR, CR, EPDM, NBR, FKM, NR, Silicone, CSM, IIR, FVMQ, HNBR

The data is based on ASTM standard testing and is authentic and reliable.

However, in special cases, different formulas can be added to meet your more specific practical application scenarios. Please contact AOBO, and our engineers can provide more detailed material selection suggestions.

Chemical Adaptability of Various Rubber Materials

The chemical compatibility comparison table of AOBO’s rubber sheet materials is as follows: clearly showing the key performance indicators of acid resistance, alkali resistance, oil resistance, etc. of each category (such as NBR, EPDM, FKM, etc.), helping you quickly select the material solution that best matches the working conditions.

Different Rubber Sheet Materials: CR, SBR, EPDM, NBR, IIR, Hypalon, VMQ, HNBR, FKM, FFKM, FVMQ, FEPM, Silicone

Different Chemical Adaptability: Resistant to Acids, Oils, Steam, Ethers, Alcohols, Alkali, Ketones, Amines, Aldehydes.

Divided into 4 Grades: Excellent, Good, Fair, Poor

All data are verified by ASTM standard tests, providing a scientific basis for material selection for your equipment sealing and pipeline applications.

The above parameters are for reference only. Due to the different acids (such as dilute sulfuric acid, hydrochloric acid, acetic acid, etc.), alkalis, oils, and their concentration differences may have different effects on various rubber products. Please confirm with the AOBO technical department for specific tolerance performance.

AOBO Rubber Strips Packaging

AOBO offers different packaging ways for rubber strips, you can choose or we can suggest to you.

Packaging According to Your Requirement.

Yes, we support cutting special-shaped contours (drawings are required)

Yes, our rubber stripes complies with international environmental standards such as RoHS and REACH, is non-toxic and harmless, and is suitable for industries with high environmental requirements.

When choosing a rubber sheet, you should focus on below parameters: material, hardness, thickness, and usage environment.

Material decides the rubber strips’ various physical and chemical properties

Hardness is expressed in Shore A, and the common range is 40-80 Shore A.

The thickness is selected according to the load-bearing requirements.

For the usage environment, for example, if you want weather resistance is related to whether it is used outdoors.

Related Hot Sell Rubber Sheets

Width 2 cm—80 cm. Different materials are available, with flexible customization.