AOBO Sandwich Rubber Performance

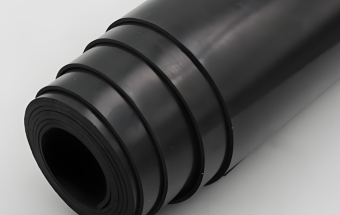

- Product Type: Composite Rubber Sheet, Multi-layer Rubber Sheet

- Polymer Type: NR/SBR

- Finish Type: Both sides smooth

- Product Features: Anti-drying and high impact resistance

- Colors, Thickness, Tensile strength can be customized

- Usage: Mining Equipment Rubber Protection

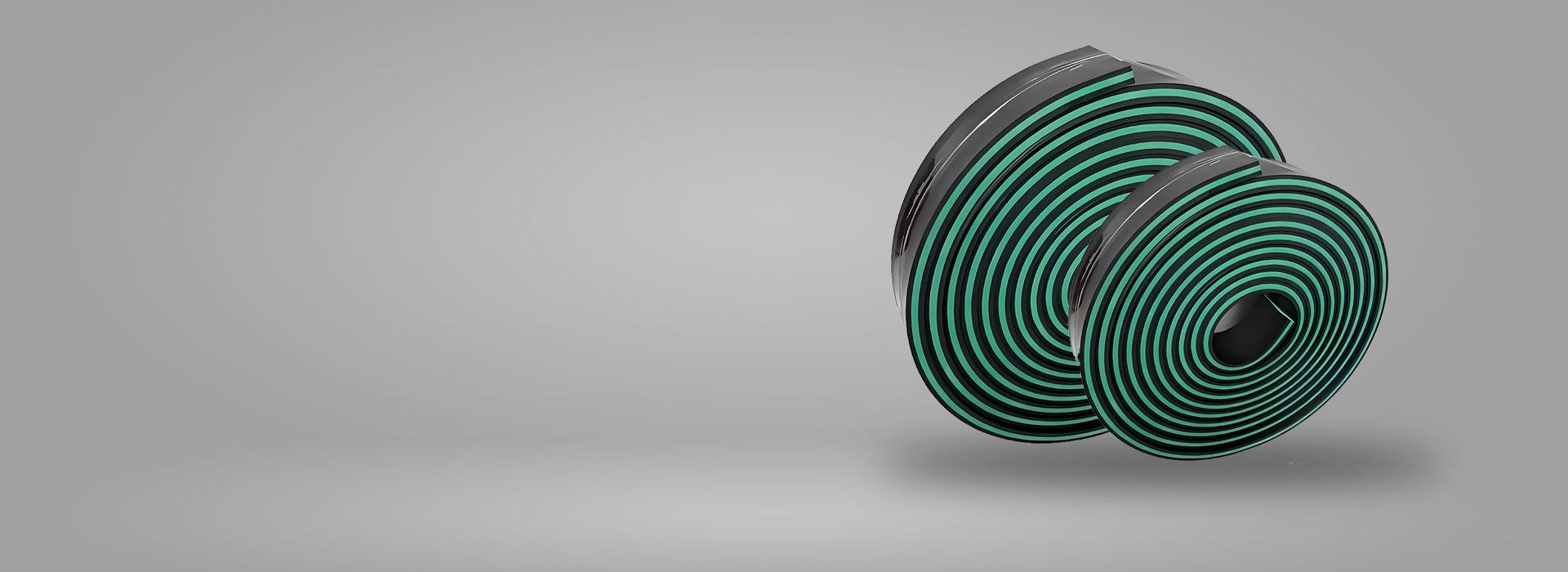

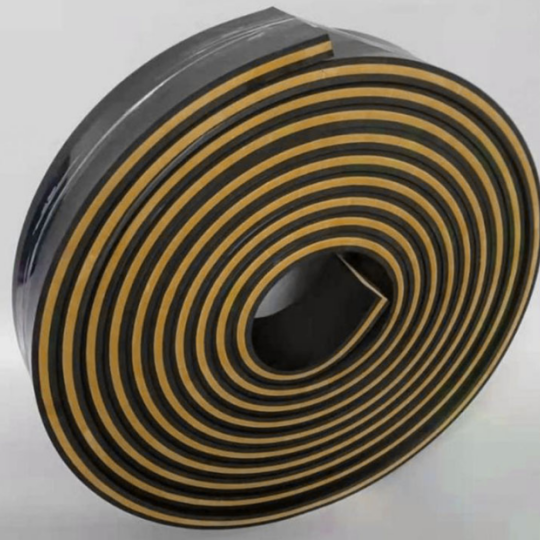

AOBO Sandwich Rubber

AOBO Sandwich Rubber Sheet is a multi-layer rubber sheet designed specifically for the mining and quarrying industries.

AOBO Sandwich Rubber structural features include upper and lower layers with high wear and cut resistance to withstand handling rough mining materials, while the inner layer structure provides good support and increases sliding when transporting materials.

For the production of AOBO sandwich rubber products, you intend to purchase, they will be shipped directly from the AOBO factory, eliminating intermediate links and saving you a lot of time and communication costs. Each batch of AOBO sandwich rubber products undergoes layers of strict quality inspection, from raw material testing to in-process quality control and final product inspection. This ensures that your products have no quality problems, whether it’s the material composition, hardness, or other key performance indicators.

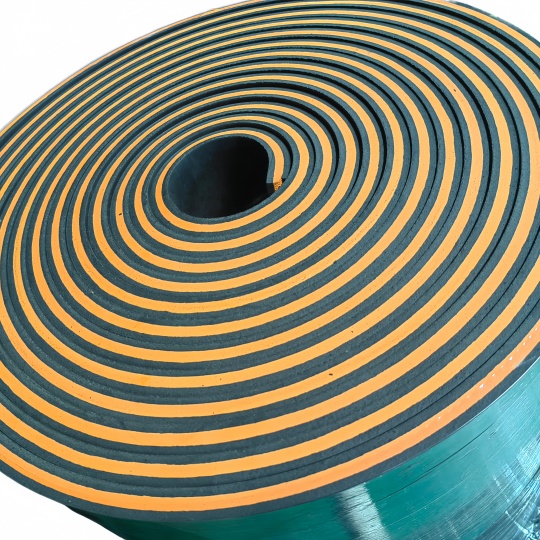

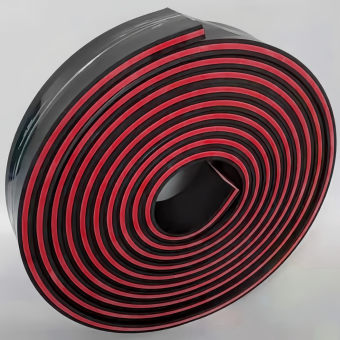

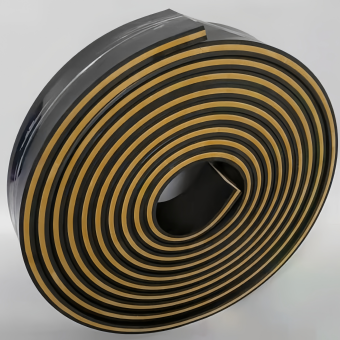

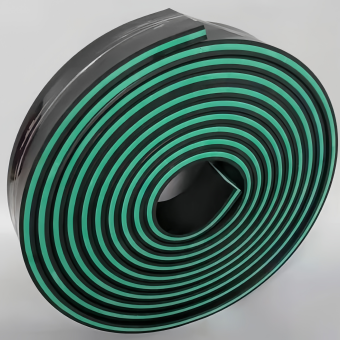

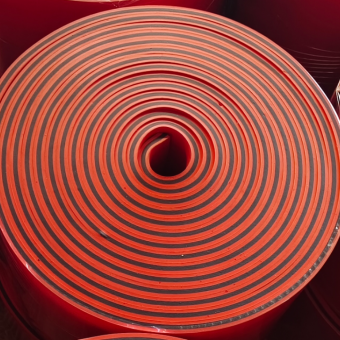

You can Customize the Color of the Sandwich Rubber

Sandwich Rubber color can be black+green+black, red+black+red, black+orange+black, etc., or customized as you asked.

It has excellent resistance to dry abrasion and high impact.

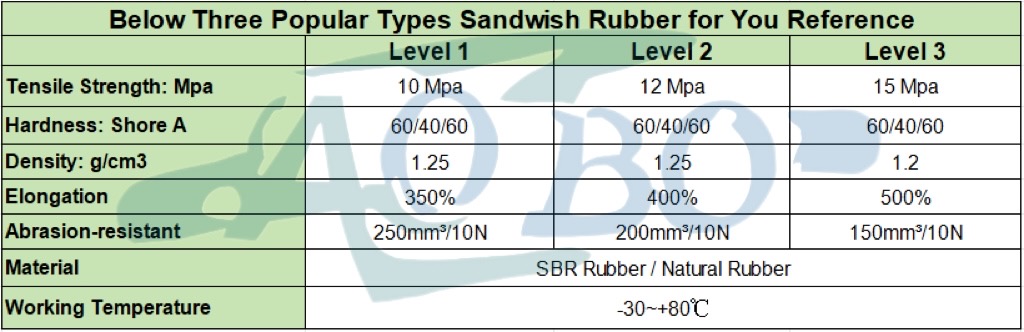

3 Types Popular Sandwich Rubber Specifications

Based on AOBO’s 20 years of industry experience, we suggest these 3 types sandwich rubber sheet, which are hot-selling grades and specifications in the market, to provide you with professional selection reference.

Three Types that differ in Tensile Strength, Elongation, and abrasion resistance.

Sandwich Rubber Available Size

AOBO provides comprehensive sandwich rubber size and customization services for size, covering the hot-selling sizes, and available sizes for your reference.

| Sandwich Rubber Sheet | Thickness | Width | Length |

| In Rolls Available Size | 6-20mm | 0.1-2m | 1-20m |

| In Pieces Available Size | 20-50mm | 0.1-2m | According to your requrie |

5 Core Advantages of AOBO Sandwich Rubber

- Various materials and colors available for you to choose from: The laminated of AOBO sandwich rubber can be made into different colors so that you can clearly distinguish them.

- Life extended by 3 times, overall lower cost: Compared with ordinary rubber sheets, the service life in high wear areas of mines is increased by 2-3 times.

- Flexible size: In rolls/sheets, and different sizes allow you to use them in different scenarios.

- Strict quality control, global certification: passed ISO 9001 quality management system, in line with mine safety standards

- Technical team: 20 years of industry experience, helps you choose the suitable one

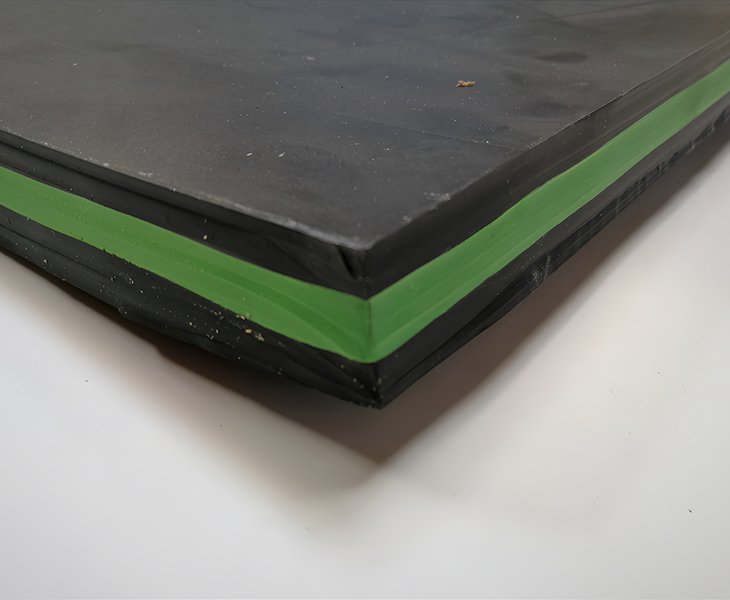

Why Name Called Sandwich Rubber?

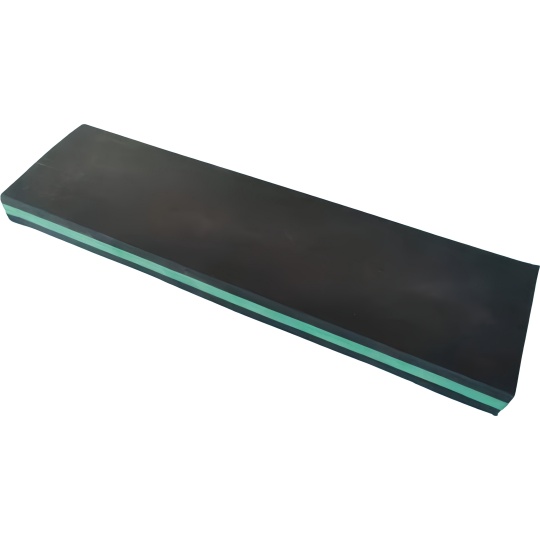

Unique three-layer combination, AOBO sandwich rubber sheet normally uses high elastic natural rubber and wear-resistant SBR rubber sheet combined layers. SBR+NR+SBR or NR+SBR+NR.

The outer/upper layer provides a scraping and cleaning effect. It is also highly wear—and cut-resistant, allowing it to withstand handling rough mining materials.

The middle damping layer provides extra flexibility and impact resistance. Also can give good support and increase sliding when transporting materials.

The outer/bottom layer has high wear and cut resistance to withstand the handling of rough mining materials. protects the softer middle layer to provide a durable and hard-wearing solution.

Superior Durability of AOBO Sandwich Rubber

The multi-layer structure of AOBO sandwich rubber enhances its strength, making it highly resistant to abrasion, impact, and harsh environments. It has high elasticity and can recover to its original shape after a certain pressure, effectively absorbing vibration and impact, and protecting equipment and the ground.

The layered design effectively absorbs shock and vibration, protecting your machinery, vehicles, and structures from excessive stress. In addition, it has excellent tear resistance, and the middle reinforcement layer can share the external force to prevent the rubber layer from being easily torn when punctured or stretched by sharp objects.

AOBO Sandwich rubber helps reduce operational wear and extend service life. Also, sandwich rubber reduces noise and vibration in mechanical and structural applications, improving your comfort and efficiency.

Easy Installation & Low Maintenance

AOBO Sandwich rubber is a multi-layered composite material designed for enhanced strength, durability, and vibration absorption in industrial and commercial applications.

It has shown extremely high convenience and economy, and is deeply favored by the majority of users.

When designing, AOBO fully considered the convenience of the installation process. Not only is it light in weight, but it also does not require too much manpower and material resources during transportation and operation.

Construction personnel can easily and accurately cut it using conventional tools according to specific installation requirements.

Application Scenarios of Sandwich Rubber

Sandwich rubber sheets are mainly used in the mining industry, mainly to protect the different equipment in mining.

Sandwich rubber sheets can be used as cleaning devices on both sides of the conveyor belt to wipe off dust and wet slurry to prevent the conveyor belt from bringing them back and accumulating them on the roller. Also can use as ore conveyor lining, vibrating screen seal, crusher feed inlet buffer…

Applicable to: sand and stone quarries, aggregate and cement industries, foundries, mechanical engineering, concrete plants, etc. Also used in the Construction industry, manufacturing industry, industrial field, etc.

AOBO company is firmly committed to sustainable development. For our sandwich rubber production, we use recyclable materials and adopt eco-friendly processes. This not only minimizes waste but also lessens environmental impact while fully supporting green initiatives. This will also ensure that your business is green and environmentally friendly.

Choose thickness according to the impact energy of the equipment:

10-15mm: small vibrating screen

20-30mm: medium-sized crusher

30-50mm: conveyor transfer point with ore drop > 3m

Contact AOBO for detailed suggestions.

Depending on the application and conditions, laminated rubber can last for years while maintaining its strength and performance.

You can contact us through our website or our customer support team with your specifications to receive tailored solutions and pricing.

Related Hot Sell Mining Rubber

Width 2 cm—80 cm. Different materials are available, with flexible customization.

High elasticity and wear resistance, made of NR/SBR. 10MPa 15MPa popular.

Diamond pattern, excellent anti-slip and wear resistance, with CN-layer.