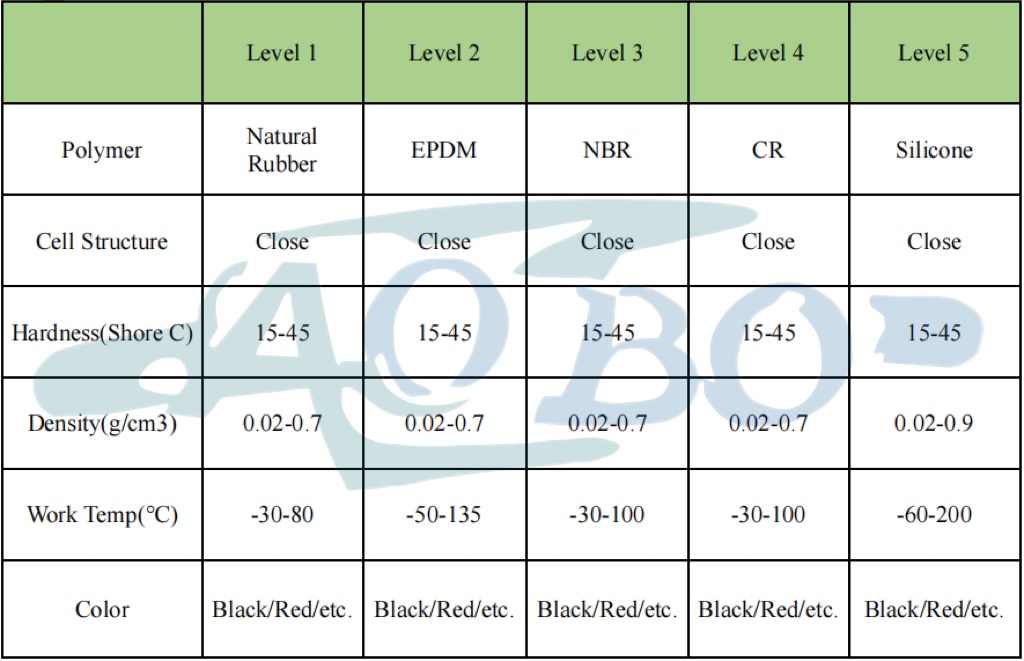

5 Types Popular Sponge Rubber Sheet Specifications

Based on 20 years of industry experience, AOBO has selected 5 types of hot-selling sponge rubber sheets to provide professional solutions for different application scenarios:

✔ Multiple material options: EPDM, CR, NBR, SBR, Silicone

✔ Data-supported decision-making: Each type in detailed physical parameters (density, hardness, temperature resistance)

AOBO Sponge Rubber Sheet

Sponge rubber sheet is a porous structural material that combines the elasticity of rubber and the lightweight properties of porous materials.

AOBO Sponge rubber sheet have different types, the most hot sell one is EPDM sponge sheet. If you looking for elastic and softness sponge rubber sheet, EPDM Sponge rubber sheet is your best choice, it have a wide range of application prospects in many fields.

AOBO rubber sponge sheet has become the first choice of customers around the world. With excellent quality, versatility and competitive prices, our products have won the trust of various industries around the world. Contact us now to help you explore your business easily.

Sponge Rubber Sheet Available Size and Size Tolerance

Professional Sponge Rubber Sheet Size Solutions

AOBO provides different sizes of sponge rubber sheets and customization services: covering popular sizes in the market for your reference, or customized sizes according to your requirements.

| Sponge Rubber Sheet | Thickness(mm) | Width(m) | Length(m) |

| Popular Size in Rolls | 3-20mm | 1m, 1.2m | 10-20m |

| Popular Size in Pieces | 25-50mm | 1m, 1.2m | 1-2m |

| Available Size | 3-50mm | 1-1.2m | 10-20m |

| Customized size available |

All sponge rubber sheet sizes strictly follow AOBO quality inspection standards.

According to the specific requirements of your order, 100% meet your standards and ensure that the quality is accurate.

AOBO Sponge Rubber Sheet Advantages

- Different colors, sizes, specifications, and materials are available.

- Customizable size and color.

You can enjoy China factory price with fast and reliable delivery, also our products is environmentally friendly and non-toxic (passed European REACH, ROHS, low aromatic PAHS testing)

AOBO Sponge rubber sheet made from premium-grade raw material to make sure super quality, can long-term use high-temperature resistance up to 135 degrees Celsius.

EPDM Sponge Rubber Sheet

- Material:100% EPDM

- Popular Color: Black, Red

- Popular Specification below:

- Hardness ( 30±5 Shore C), Density (0.5 ±0.05 g/cm3), Tensile Strength (≥0.7 Mpa)

- Hardness ( 30±5 Shore C), Density (0.35 g/cm3), Tensile Strength (≥0.5 Mpa)

- Also have hardness in 15±5 Shore C, 25±5 Shore C

Features of AOBO EPDM Sponge Rubber Sheet.

Closed-cell sponge rubber sheets have independent bubbles that are not connected to the outside world.

AOBO EPDM Sponge rubber sheet advantages include high compression and elastic properties, excellent heat insulation performance, good sound absorption performance, and excellent shock resistance.

- Excellent aging resistance, UV resistance, and ozone resistance

- Good shock absorption

- Good softness, bending resistance, cold resistance, heat resistance, and waterproof

- Corrosion resistance and chemical resistance

Application Areas of AOBO Sponge Rubber Sheets

AOBO Closed-cell foam/ Sponge rubber sheet is commonly used in a variety of applications such as sealing, heat insulation, sound insulation, shock absorption and sealing pads.

- Industrial field, the wrapping of pipes plays a role in heat preservation and heat insulation;

- Construction field, it can be used for sound insulation and heat insulation, such as filling in walls or roofs to reduce noise and heat transfer;

- Also use in automotive industry and packaging industry, air-conditioning system and so on.

Chemical Adaptability of Various Rubber Materials

The chemical compatibility comparison table of AOBO’s rubber sheet materials is as follows: clearly showing the key performance indicators of acid resistance, alkali resistance, oil resistance, etc. of each category (such as NBR, EPDM, FKM, etc.), helping you quickly select the material solution that best matches the working conditions.

Different Rubber Sheet Materials: CR, SBR, EPDM, NBR, IIR, Hypalon, VMQ, HNBR, FKM, FFKM, FVMQ, FEPM, Silicone

Different Chemical Adaptability: Resistant to Acids, Oils, Steam, Ethers, Alcohols, Alkali, Ketones, Amines, Aldehydes.

Divided into 4 Grades: Excellent, Good, Fair, Poor

All data are verified by ASTM standard tests, providing a scientific basis for material selection for your equipment sealing and pipeline applications.

The above parameters are for reference only. Due to the different acids (such as dilute sulfuric acid, hydrochloric acid, acetic acid, etc.), alkalis, oils, and their concentration differences may have different effects on various rubber products. Please confirm with the AOBO technical department for specific tolerance performance.

Sponge Rubber Sheet Packaging

AOBO offers different packaging ways for Sponge Rubber Sheet, you can choose or we can suggest to you.

Packaging According to Your Requirement.

Spong Rubber Sheet, it is a foam board made of rubber raw materials such as NR, EPDM, NBR, CR, SILICONE and plastic raw materials such as EVA, PE .

- First, it is necessary to clarify the specific use of sponge rubber sheet. For example, in the construction industry, sponge rubber sheet is often used as heat insulation and sound insulation materials. At this time, it is necessary to choose products with good heat insulation and sound insulation performance;

- Secondly, determine the required density and thickness according to the purpose. The higher the density, the better the elasticity of the material and the better the sound absorption effect;

- In addition, the hardness and elasticity of the sponge rubber sheet need to be considered. Different hardness and elasticity are suitable for different application scenarios.

- Contact AOBO, we will give you professional advice.

Sponge rubber sheets are divided into closed-cell and open-cell types.

AOBO sponge rubber sheet is closed-cell.

Open-cell sponge rubber sheets have interconnected pores. This structure allows air and moisture to easily pass through the pores, giving the open-cell sponge sheet good air permeability and water absorption.

Open-cell foam sheet are mainly used for sound-absorbing materials, such as sound-absorbing panels in conference rooms and recording studios;

in the packaging field, they are used to package some products that require air permeability; they are also used to make cleaning supplies, filter materials, such as cleaning sponges, air filters, etc.

Related Hot Sell Rubber Sheets

NBR is known for its oil resistance, especially suitable for fuel and lubricating oil environments.

Ultra-wide temperature range (-60℃~230℃), excellent weather resistance, and insulation.

Natural rubber sheet has the best elasticity and high tensile properties/strong tear resistance.

CR has outstanding performance in ozone resistance, weather resistance and flame resistance.