At AOBO, we pride ourselves on our rubber milling and blending expertise. With the latest equipment and a skilled team, AOBO offers all rubber products that meet the highest quality and performance standards to meet your different needs of various industries.

1. What is Rubber Milling?

Rubber milling, or rubber compounding or mixing, is an important industrial process used to convert raw rubber into high-performance materials. The process is essential for producing rubber compounds that meet specific mechanical, to be used in different applications.

2. The Rubber Milling Process: It can be described by a metaphor: it is the process of making raw flour into smooth dough, then the Vulcanization process is similar to making the dough into noodles or bread.

Rubber milling is typically performed using a “two-roll mill,” a machine consisting of two parallel rolls that rotate in opposite directions. Here is a step-by-step breakdown of the process:

1) Raw Material Preparation: Raw rubber (natural or synthetic) is mixed with additives such as fillers, plasticizers, curing agents, antioxidants, and colorants. These additives enhance the properties of the rubber, such as strength, elasticity, and heat or chemical resistance. Just like using the raw flour, baking powder, and water to mix first.

2) Feeding: The rubber mixture is fed into the gap between the two rolls of the mill. The rolls rotate at different speeds, creating shear forces to process the rubber. Like to mix the raw flour, baking powder, and water to mix thoroughly in the machine.

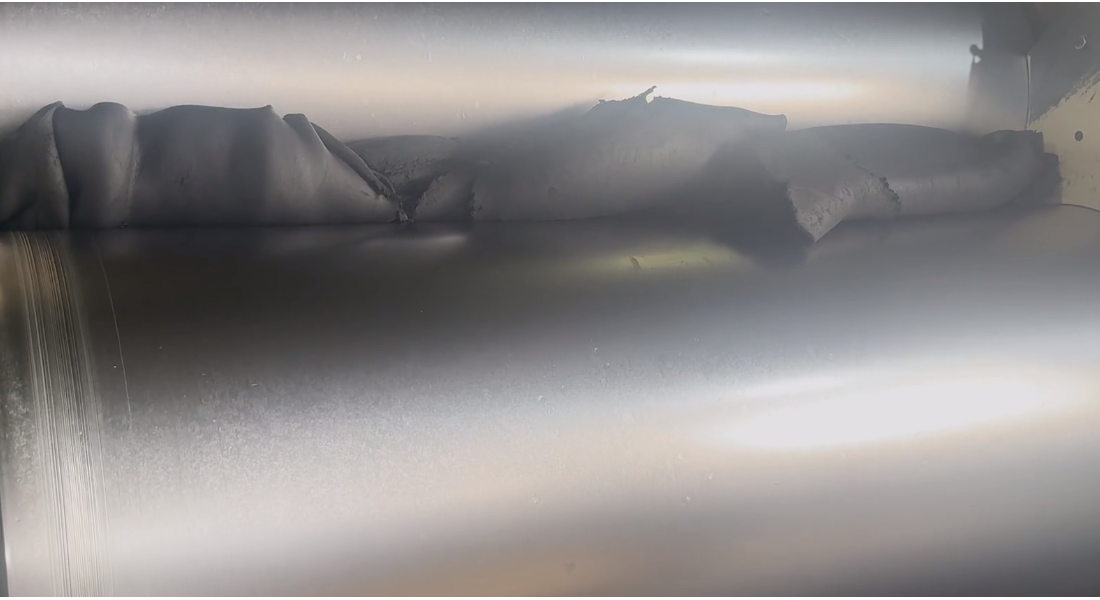

3) Shearing and mixing: As the rubber passes through the rollers, it is subjected to intense mechanical shearing. This process breaks down the molecular structure of the rubber, allowing the additives to be evenly dispersed throughout the material.

4) The rubber is repeatedly passed through the rollers to ensure uniform mixing. This step is critical to achieving consistent quality and performance of the final product. Like the dough is repeatedly rolled until to very smooth.

5) Sheet formation: Once the rubber is thoroughly mixed, it is formed into sheets or strips. These sheets can then be cut, molded, or further processed into finished products. Just like the smooth dough to make bread or noodles is ready.

3. Why is rubber milling so important?

Rubber milling plays a vital role in the rubber industry for the following reasons:

– Enhanced material properties: The process improves the tensile strength, elasticity, and durability of rubber, making it suitable for demanding applications.

– Customizable: By adjusting the formulation of additives, rubber compounds can be customized to meet specific requirements, such as resistance to extreme temperatures, chemicals, or abrasion.

– Rubber milling ensures that the composition of each batch of rubber is uniform, which is critical to maintaining product quality.

– The process can be applied to a wide range of rubber types, including Natural rubber, EPDM, SBR, NBR, FKM, and silicone rubber, etc.

In summary, rubber milling is an essential process for transforming raw rubber into a versatile, high-performance material. AOBO can create rubber compounds that meet the unique needs of each industry. If you are looking for reliable rubber products, trust AOBO to provide solutions that combine quality, durability, and innovation.