AOBO Thin Rubber Sheet Performance

- Thickness range (0.4-1mm ultra-thin rubber sheet)

- Types: NBR, CR, EPDM, fluororubber, silicone

- Uniform and precise thickness

- Smooth surface without flaws, no bubbles inside

- International standard quality certification, quality guaranteed

- Permanent sealing, very durable

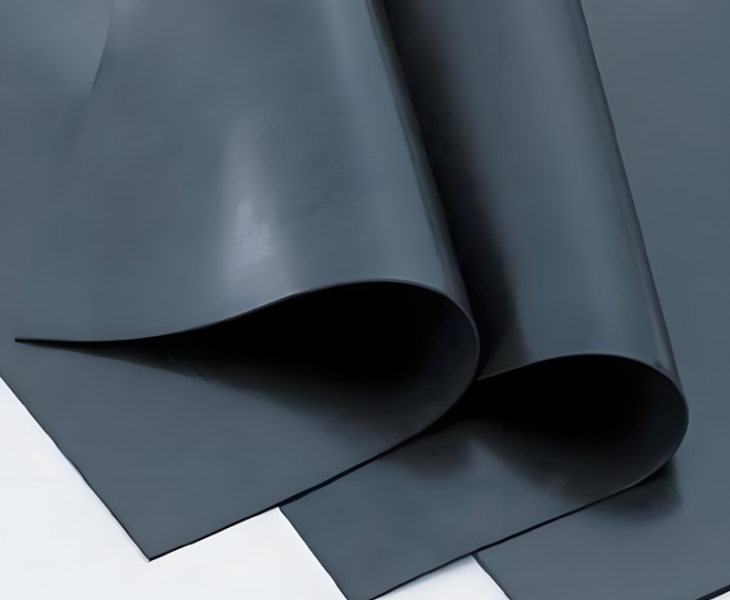

Thin Rubber Sheet

Ultra-thin rubber sheet refers to a thinner rubber sheet, usually with a thickness of 0.4 mm- 0.5mm- 0.6mm- 0.7mm- 0.8mm to 1mm. This material has many excellent properties.

The thin rubber sheet production process includes mixing, calendering, and vulcanization. It is difficult to achieve this thickness with traditional rubber processing methods because rubber is prone to deformation and flow during processing. In addition, extremely thin rubber layers may have difficulty maintaining their structural and performance stability, thus affecting the service life and reliability of the product.

AOBO’s researchers and engineers continue to develop and improve production processes to produce ultra-thin rubber sheets with extremely competitive stability, ensure uniform thickness, and use high-purity raw materials to ensure product service life and effect, thereby ensuring that your project is perfectly achieved.

Popular 5 Materials Thin Rubber Sheet Specifications

Based on AOBO’s 20 years of industry experience, we suggest these 5 types of Thin Rubber Sheet, which are hot-selling grades and specifications in the market, to provide you with a professional selection reference.

Below is Thin NBR Rubber Sheet, Thin CR Rubber Sheet, and Thin EPDM Rubber Sheet specifications. All material is pure grade, including consistent tensile strength, hardness, density, and if you need other types not shown below, that also available. AOBO can customize as you asked, just feel free to contact AOBO.

| Thin NBR Rubber Sheet | ||

| Grade | Pure NBR | High Grade Pure NBR |

| Tensile Strength: Mpa | 5 Mpa | 10 Mpa |

| Hardness: Shore A | 65±5 | 65±5 |

| Density: g/cm3 | 1.4 | 1.3 |

| Thin CR Rubber Sheet | ||

| Grade | Pure CR | High Grade Pure CR |

| Tensile Strength: Mpa | 7 Mpa | 12 Mpa |

| Hardness: Shore A | 65±5 | 65±5 |

| Density: g/cm3 | 1.5 | 1.5 |

| Thin EPDM Rubber Sheet | ||

| Grade | Pure EPDM | High Grade Pure EPDM |

| Tensile Strength: Mpa | 7 Mpa | 12 Mpa |

| Hardness: Shore A | 65±5 | 65±5 |

| Density: g/cm3 | 1.3 | 1.2 |

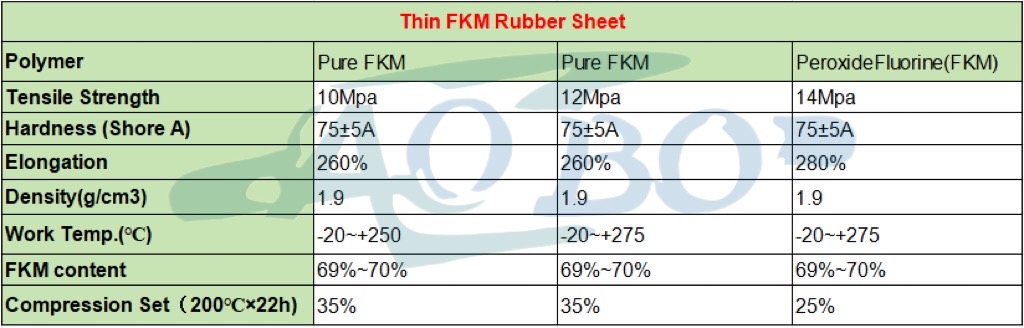

Thin FKM Rubber Sheet & Thin Silicone Rubber Sheet

Below are Thin FKM Rubber Sheet and the Thin Silicone Rubber Sheet specifications, just showing the hot-selling ones, data include tensile strength, hardness, density, temperature resistant range, elongation, and so on. If you need other types, just contact AOBO is ok.

Thin Silicone Rubber Sheet has different types: industrial type silicone, food grade silicone, gas phase silicone, fire-resistant silicone, laminating machine silicone, and laminator silicone. Details see photo below.

![]()

Thin Rubber Sheet Available Size

AOBO offers different types thin rubber sheet, and available size see below:

| Thickness | Width | Length | |

| Ultra Thin Rubber Sheet | 0.4-1mm | 1m | 10m or customized |

AOBO Available Thin Rubber Material

Thin rubber gasket material: According to your sealing scene requirements, you can choose NBR, CR, EPDM, FKM, or Silicone.

Color: thin white rubber sheet, thin black rubber sheet, thin translucent rubber sheet…

Features:

NBR has good oil resistance and wear resistance.

CR has excellent oil resistance, flame resistance, oxidation resistance, and ozone resistance

EPDM has excellent weather resistance, ozone resistance, and electrical insulation

FKM (fluororubber): has excellent chemical resistance and high temperature resistance

Silicone (silicone rubber): has excellent high and low temperature resistance and can be used in a very wide temperature range

AOBO Thin Rubber Sheet Quality Advantage

In the field of ultra-thin rubber sheets, conventional production processes are limited by traditional calendering technology, and it is often difficult to avoid millimeter-level thickness fluctuations. This deviation may cause uneven interface stress and sealing problems, and other systemic risks in scenarios such as high-end sealing and precision buffering required in your project or equipment.

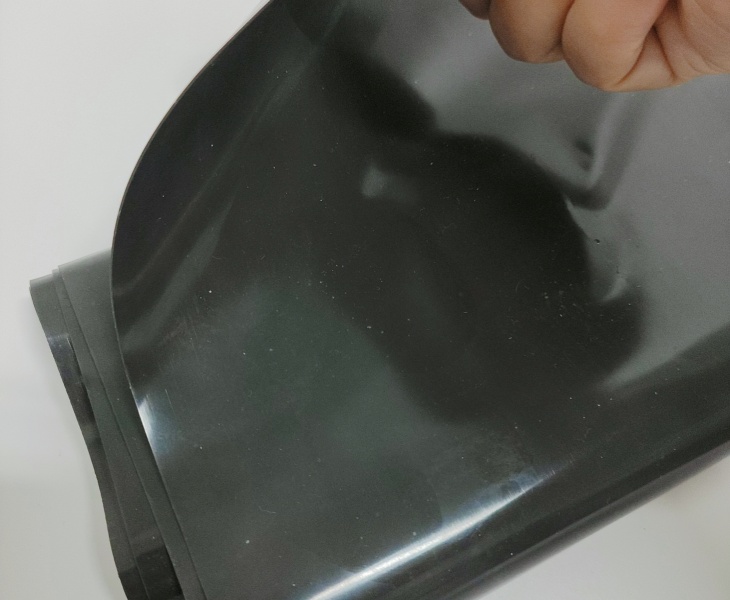

AOBO’s innovatively developed precision production calendering system can ensure that the thickness of the rubber sheet is very uniform, eliminating uneven thickness, and there are no bubbles, defects, impurities, and the surface is intact and not easy to deform.

Ensure that every piece of thin rubber sheet delivered to you meets the requirements of aerospace-grade dimensional stability and uniformity. It has high strength and excellent tensile deformation performance.

Thin Rubber Sheet--NBR

Pure NBR: This product is suitable for environments immersed in oil, and when the oil temperature does not exceed 120℃, it can meet your use requirements of high-demand workbenches and gasket seals.

High-grade pure NBR: Especially suitable for your oil immersion environment, can be soaked in oil and used, belonging to the high-level class C oil-resistant product; Ensure that the volume change rate of the product in the oil-resistant place is minimal.

It can also be used in medium-high temperature oil at 100-120 degrees.

Thin Rubber Sheet--CR

Designed specifically for your use needs in acid and alkaline environments, it can provide you with reliable protection whether it is used for immersion or for daily oil resistance and aging resistance needs.

Pure CR: This product can achieve the effect of use in acid and alkali environments; For product soaking or general oil resistance, aging resistance is no problem, and various chemical corrosion resistance sealing links are OK.

High grade pure CR: Can be used in acid and alkali environments, in some marine industries, for advanced corrosion prevention, flame retardant, and in other industries can be used. Ensure that the product has the longest service life and the smallest change rate in each environmental product.

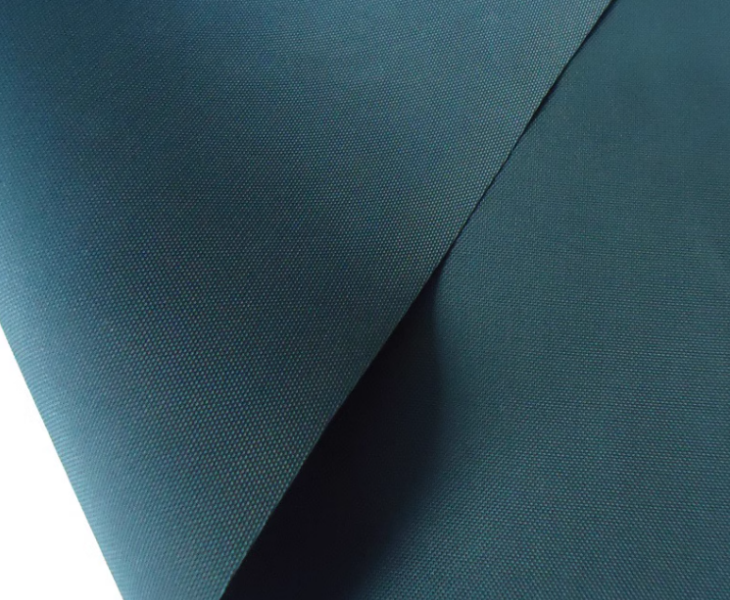

Thin Rubber Sheet - EPDM

Pure EPDM: Temperature-resistance: 100-120℃; It can also be used under regular acid and alkali soaking for you.

The advantage is that the anti-aging effect is obvious when you use outdoor, such as automotive radiators and automotive brake systems, and the seals in the automotive industry can be used.

High grade pure EPDM: Temperature-resistance:120-140℃; This product can be used in any place you need, including high-temperature water vapor environments in the sealing, outdoor laying, dilute acid, and alkali occasions, and automotive sealing, which requires the best anti-aging effect on the choice of this product.

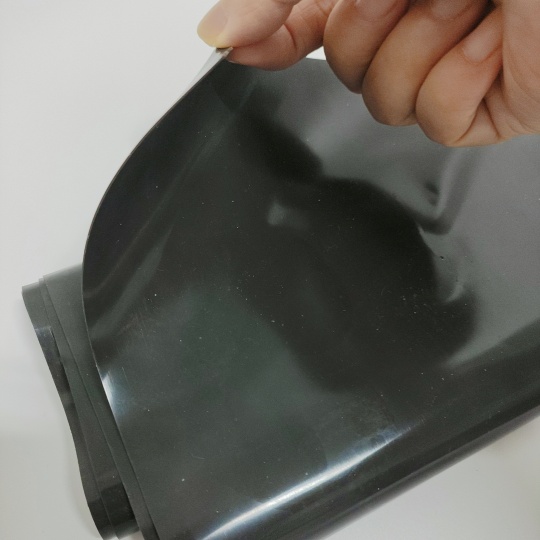

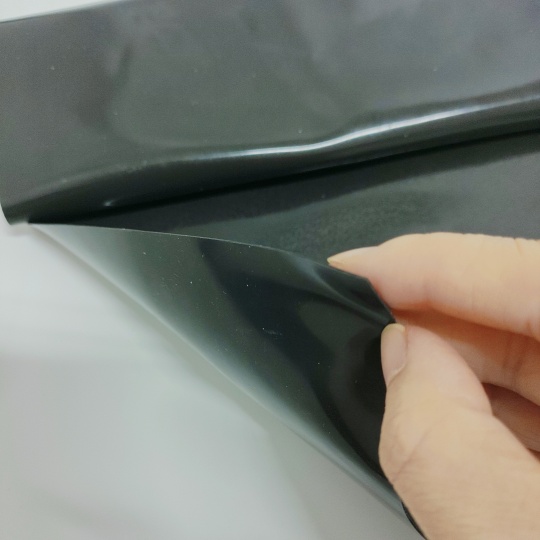

Ultra-Thin Fluorine Rubber Sheet

The FKM content can reach 69%-70%, Temperature resistance -20℃ — 275℃. It can be soaked in dilute sulfuric acid for a long time.

Excellent overall performance, suitable for your different uses, like energy storage batteries, as an excellent accessory. It can be used as a diaphragm in energy storage battery packs.

AOBO ultra-thin FKM rubber sheet has uniform thickness, is acid and alkali resistant, high temperature resistant, has no impurities, and is not easy to deform.

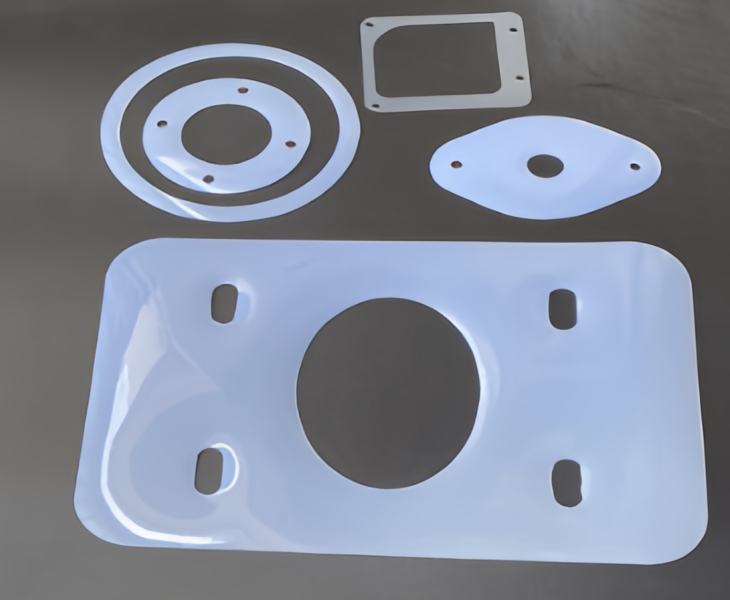

Ultra-Thin Silicone Sheet

Using new silicone raw materials, pure and free of impurities, with good chemical stability, environmentally friendly, and non-toxic.

Transparent silicone is pure and transparent, with good light transmittance and high clarity.

Soft and tough, tear-resistant, not easily aged, long life, high and low temperature resistance, no deformation, and no fear of harsh environments.

Customizable, cuttable, widely used for your project, and offers dust-proof film packaging for you. High precision makes AOBO’s products even better.

AOBO Thin Rubber Sheet Application Scenarios

Ultra-thin rubber sheet, your multi-field protection expert.

Widely used in automobiles, new energy, precision industry, power systems, precision sealing of medical devices, etc. For example, it is often used in the sealing and shock absorption of various equipment, such as automobile seals, etc., which can effectively prevent the intrusion of dust and noise. It is also widely used as an insulating material in power systems, as a diaphragm in energy storage battery packs, and also used for anti-corrosion, wear-resistant, and impact-resistant protection of equipment and devices.

Vertical Content Block

Lorem ipsum dolor sit amet, mei graecis tacimates te, sed cu nisl explicari, ex dicam tempor euismod pri. Iusto percipit inciderint nec an, mel an utinam offendit. Audire discere instructior vel at.

Ut semper ipsum ex, quis aliquet justo pretium a. Suspendisse scelerisque metus augue, a interdum leo iaculis sed. Vivamus sit amet nunc odio.

Ut semper ipsum ex, quis aliquet justo pretium a. Suspendisse scelerisque metus augue, a interdum leo iaculis sed. Vivamus sit amet nunc odio.

Ut semper ipsum ex, quis aliquet justo pretium a. Suspendisse scelerisque metus augue, a interdum leo iaculis sed. Vivamus sit amet nunc odio.

Ut semper ipsum ex, quis aliquet justo pretium a. Suspendisse scelerisque metus augue, a interdum leo iaculis sed. Vivamus sit amet nunc odio.

Vertical Content Block 2

Lorem ipsum dolor sit amet, mei graecis tacimates te, sed cu nisl explicari, ex dicam tempor euismod pri. Iusto percipit inciderint nec an, mel an utinam offendit. Audire discere instructior vel at.

Ut semper ipsum ex, quis aliquet justo pretium a. Suspendisse scelerisque metus augue, a interdum leo iaculis sed. Vivamus sit amet nunc odio.

Ut semper ipsum ex, quis aliquet justo pretium a. Suspendisse scelerisque metus augue, a interdum leo iaculis sed. Vivamus sit amet nunc odio.

Ut semper ipsum ex, quis aliquet justo pretium a. Suspendisse scelerisque metus augue, a interdum leo iaculis sed. Vivamus sit amet nunc odio.

Ut semper ipsum ex, quis aliquet justo pretium a. Suspendisse scelerisque metus augue, a interdum leo iaculis sed. Vivamus sit amet nunc odio.

AOBO has various international certifications, such as SGS international quality standard certification, ISO9001 (quality management system certification), GB-T5574-2008, REACH (SVHC high concern substance content detection), ROHS (heavy metal content detection), PAHS (polycyclic aromatic hydrocarbons certification), FRAS (flame retardant static electricity), and so on.

And provide customized services and 24-hour online after-sales support.

AOBO supports small batch customization. Please contact AOBO for details.

You can share your usage scenarios (such as automotive laser radar sealing) key indicators (thickness/hardness/temperature resistance requirements), and AOBO will recommend the most suitable product for you.

Using the gas phase reinforcement process, ultra-thin silicone can work stably at -60℃~250℃.