AOBO Insulation Rubber Sheet Performance

- Material: Rubber and TPE are optional

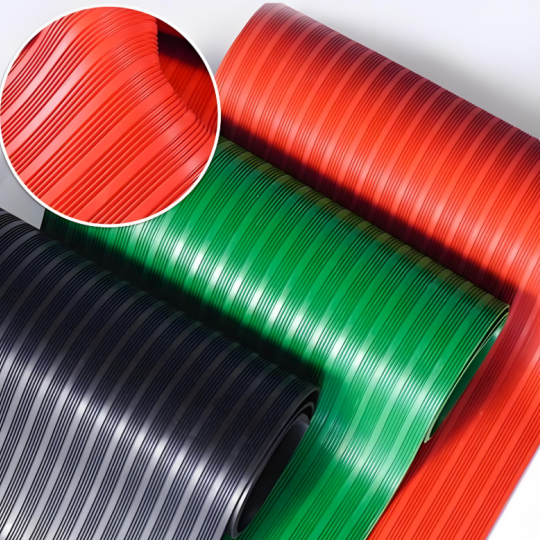

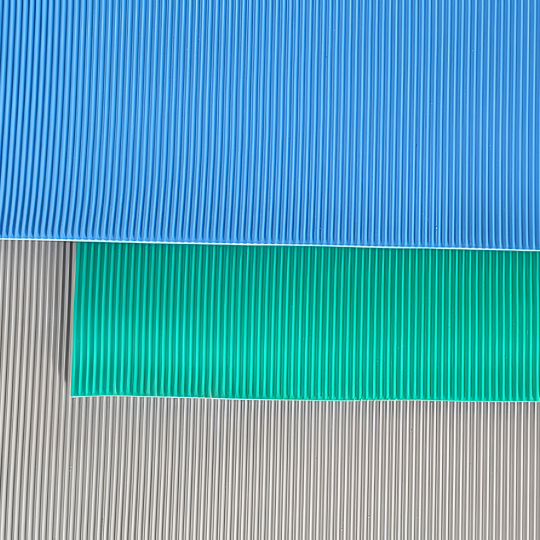

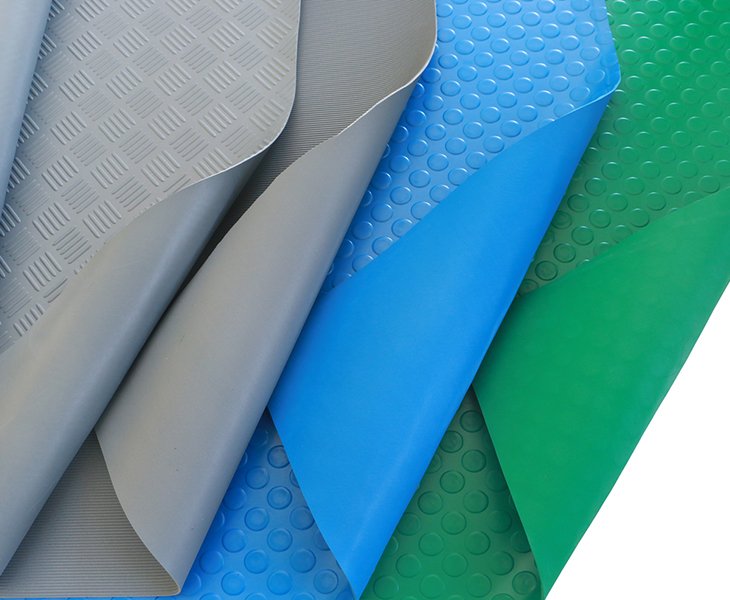

- Surface: mainly smooth and fine ribbed, and also with different patterns such as wide ribbed, coin, checker…

- Voltage resistance level: Class 0 ~ Class 4

- Mainly black, red, green, gray, and other colors are available

- Insulation indicators: can be backed with vulcanization tape or coding

- Different sizes available

- Features: Rubber sheet with large volume resistivity and resistance to breakdown

AOBO Insulation Rubber Sheet

AOBO Insulating rubber sheet is a rubber product with excellent insulation properties. Insulating rubber sheet mainly provides electrical insulation and insulation protection to prevent current leakage or short circuit between electrical appliances, and can also delay the life of the equipment, protect equipment and personnel from electric shock.

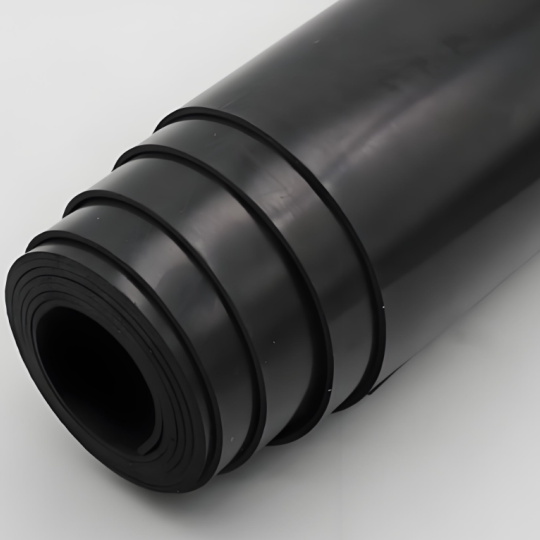

It is usually made of natural rubber, synthetic rubber or a mixture of the two, with high volume resistivity and resistance to electrical breakdown.

AOBO has 20 years of experience in the production of insulating rubber sheets. We have a full range of certificates and are very strict in testing. AOBO are familiar with the standards of working voltage, test voltage, and breakdown voltage. If you are looking for a professional insulating rubber sheet, please feel free to let us know. AOBO also provides you with factory prices and the advantages of your local selling price to achieve a win-win situation.

Classification and Voltage Rating Standards of Insulation Rubber Sheets

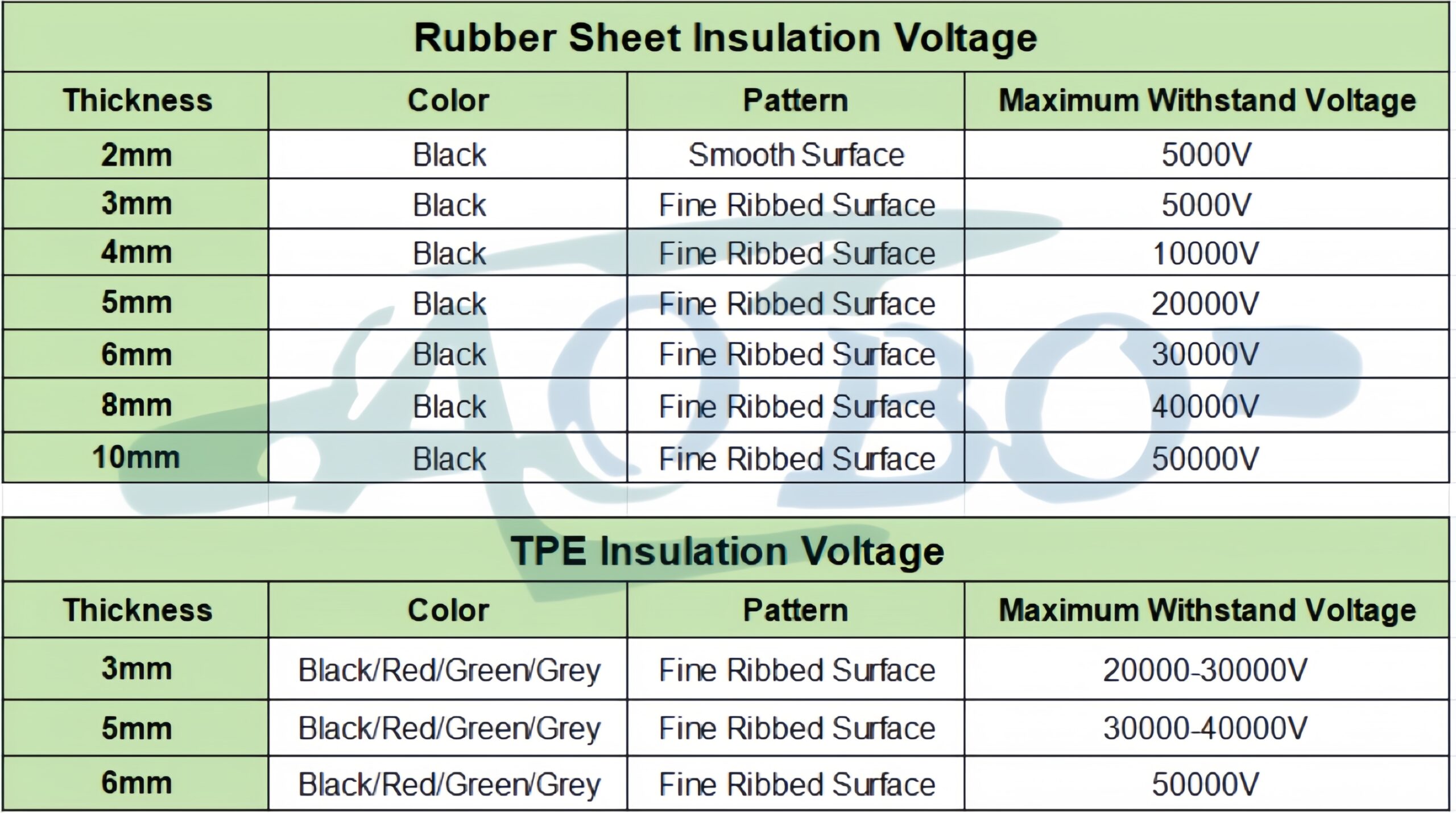

Insulating rubber sheets can be classified by color, voltage level, and thickness to meet the needs of different application scenarios.

China’s domestic standards are divided into multiple specifications, such as 5kV, 10kV, 20kV, 30kV, 40kV, and 50kV, according to the voltage rating. These standards are suitable for all-around protection from low-voltage power distribution to ultra-high-voltage equipment.

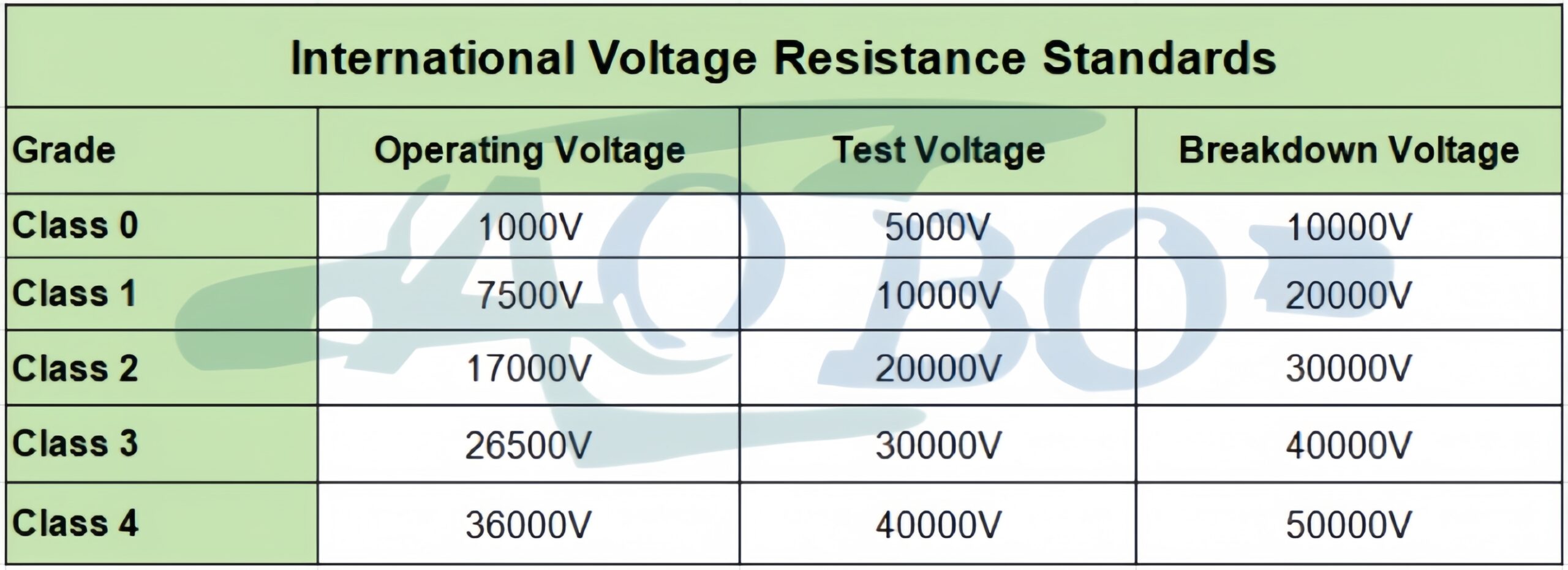

International standards use Class 0-Class 4 classification, among which Class 0 (≤1kV) is suitable for electronic equipment insulation, and Class 4 (30kV+) is designed for ultra-high voltage environments. All products have passed international certification tests such as SGS and ASTM.

AOBO provides a complete voltage parameter comparison table (including working voltage, test voltage, and breakdown voltage) to help you quickly match the most suitable insulation solution.

Working voltage is the voltage value allowed to be continuously applied to the equipment during normal operation.

Test Voltage / Experimental voltage is the voltage value used during the experiment.

Breakdown voltage is the critical voltage value that causes the dielectric or insulating material to lose its insulation properties and cause destructive discharge.

Breakdown means that the insulating sheet loses its insulation properties under the action of a strong electric field and becomes a conductor.

Popular Types Insulation Rubber Sheet Specifications

Based on AOBO’s 20 years of professional experience in the field of insulation materials, we have selected the best-selling rubber and TPE insulating rubber sheets on the market for you.

Different thicknesses correspond to different insulation levels. They are the hot-selling grades and specifications on the market, providing you with a professional selection reference.

Of course, if you want to change the thickness and voltage resistance level, please contact AOBO for specific details.

Insulation Rubber Sheet Available Size

AOBO provides comprehensive Insulation Rubber Sheet size and customization services for size, covering the hot-selling sizes, and available sizes for your reference.

| Insulation Rubber Sheet | Thickness(mm) | Width(m) | Length(m) |

| Popular Size | 2-10mm | 1-2m | 10-20m |

| Available Size | 2-50mm | 1-2m | Any |

| Smooth Surface | 3-50mm | 1-2m | 5-20m |

| Fine Ribbed Surface | 3-8mm | 1-2m | 5-20m |

Advantages of AOBO Insulation Rubber Sheet

- Material: you can choose SBR, NR, TPE, or EPDM high insulation material.

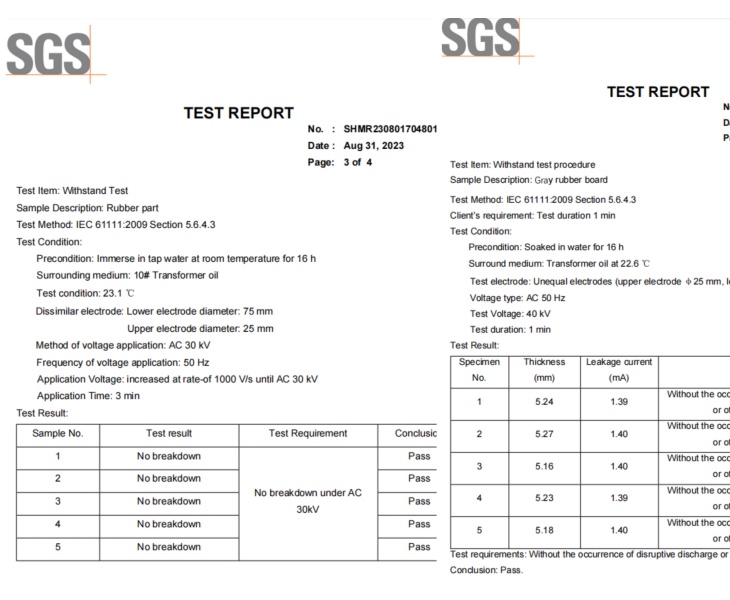

- International authoritative certification, compliance guaranteed: Complete certificates: SGS61111-2009 certificate, ASTM insulation certificate, China Institute of Chemical Industry insulation certificate, EVPU EU insulation certificate, etc.

- Super strong insulation performance, safe and worry-free

- Full coverage of voltage levels: 5kV~50kV. Standard: Class 0, Class 1, Class 2, Class 3, Class 4. Voltage resistance levels range from 1000V to 50000V.

- Customized service: thickness, color, pattern, vulcanized sticker or coding… can be customized according to your requirements.

Insulation Rubber Sheet Inspection Standards

Appearance inspection: The surface of the insulation rubber sheet should be smooth and clean, without harmful irregularities such as small holes, cracks, etc. At the same time, it should be free of odor, bubbles, and pits. The thickness measurement should be carried out at different points to ensure uniformity.

Mechanical properties inspection: such as hardness, tensile strength, and elongation at break. Hot air aging, water absorption, etc. Tests.

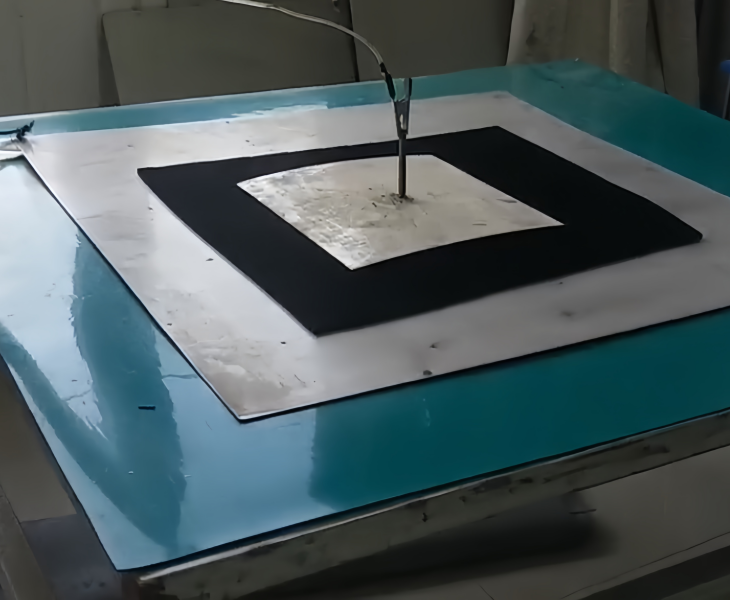

Electrical insulation performance tests: including withstand voltage test and breakdown voltage test. AOBO’s strict quality inspection standards. AOBO will test every square meter and every point of rubber insulation board to ensure the absolute safety of the product and ensure the long-term and safe development of your business.

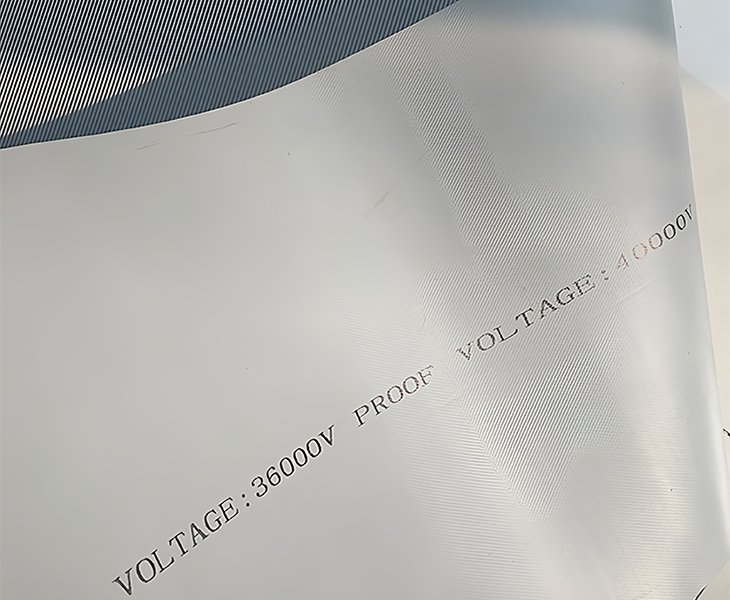

Vulcanization Sticker on the Back of the Insulating Rubber Sheet

For special identification and verification of its vulcanization effect.

The vulcanization sticker is a special label, which is usually completed during the vulcanization process of the rubber sheet, and is vulcanized and pasted on the back of the rubber sheet to identify the product as a special insulating rubber sheet.

The vulcanization sticker can ensure that during the subsequent use and maintenance of the insulating rubber sheet, the relevant personnel can clearly understand the specific voltage resistance level of the product, so as to select the appropriate insulating sheet according to the specific application requirements.

Application Scenarios of Insulation Rubber Sheet

Insulation rubber pads are key safety products in industries such as electricity and power plants.

- In power systems, AOBO insulation rubber sheet is widely used in substations, power plants, distribution rooms, laboratories, and outdoor live-line operations as a countertop or floor insulation material. Insulation protection is particularly important when the humidity is high during the rainy season.

- AOBO’s insulation rubber sheet can also serve as support and protection to prevent aging and damage to power equipment.

- Also can use in the construction and decoration industry and transportation.

Characteristics & Functions of Insulation Rubber Sheets

1. Good insulation can effectively prevent current leakage and avoid electric shock accidents. can provide a stable and reliable working environment. It can ensure the normal operation of electrical equipment.

2. Good anti-slip performance: Anti-slip pattern surface provides shock absorption and beauty. The surface of the insulating rubber sheet has a certain friction force to reduce the risk of slipping

3. Wear resistance: It can withstand the friction and wear of daily equipment movement and personnel movement, and maintain a good state for a long time.

In short, the insulating rubber sheet has strong elasticity, and the surface generally has no odor and has strong anti-aging and weather resistance, which makes it suitable for various workplaces.

They should be stored in a dry and ventilated environment, away from heat sources, and should not be contaminated by acids, alkalis and oils. They should not be stored in the open air to prevent direct sunlight.

Choose the appropriate insulating sheet according to the specific application requirements.

Pay attention to the quality and performance of the insulating sheet to ensure the safe and reliable operation of the power equipment.

During use, avoid excessive mechanical stress and high temperature on the insulating sheet.

The insulating rubber sheet has passed the SGS wet test, and it is recommended to choose an optional non-slip textured surface, which has a higher friction coefficient and is safer in a humid environment.

Related Hot Sell Flooring Mats & Rubber Sheet

Rubber Material: Eco-friendly TPE or SBR/NR. Elastic, sound-proof, shock-absorbing.

PVC material. Widely used in industrial fields due to its extremely high traction and durability.

General-purpose rubber sheeting, low cost, and good mechanical properties.