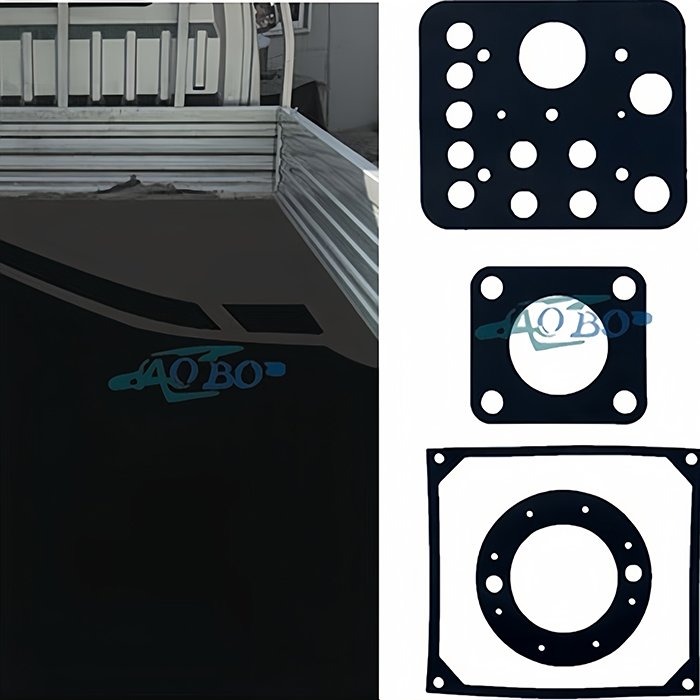

AOBO SBR Rubber Sheet Performance

- General-purpose rubber sheeting

- Low cost and good mechanical properties

- It can be one-layer or multi-layer cloth inserted to increase strength and tear resistance.

- Can be with different fabrics inserted

- Ultra-thin/Extra-width Size Available

- Different Tensile strengths or hardnesses are available

- Both sides fabric impression/ Both sides smooth/ One side smooth, the other side fabric impressed

SBR Rubber Sheet

SBR rubber sheet is one of the earliest synthetic rubber materials, which was developed to make up for the shortage of natural rubber resources during World War II. SBR rubber sheet is currently the synthetic rubber with the largest output. If you compared with natural rubber, SBR sheet has better physical properties such as processing performance, heat aging resistance and wear resistance and more favorable price. Therefore, SBR rubber sheet has become popular in many industries. SBR rubber sheet is widely used to manufacture various rubber rings, protective pads, sound insulation pads, conveyor belts, rubber pads, sealing pads and various industrial rubber products, which can be widely used in industry, construction, transportation and other fields.

AOBO is a professional rubber sheet manufacturer, which can provide you with the highest quality, factory price, 24-hour online service, and free samples. If you are looking for SBR rubber sheet, AOBO will be your best choice.

If you are interested, please feel free to contact AOBO.

4 Types Popular SBR Rubber Sheet Specifications

Based on AOBO’s 20 years of industry experience, we suggest these 4 types of SBR Rubber Sheet, which are hot-selling grades and specifications in the market, to provide you with professional selection reference.

AOBO also has different grades, tensile strength from 2Mpa, and hardness from 50±5 to 80±5 Shore A.

Also SBR rubber sheet in red color is very hot-selling.

SBR Rubber Sheet Available Size & Tolerance

Professional SBR Rubber Sheet Size Solutions

AOBO provides comprehensive SBR Rubber Sheet size and customization services for size, covering the hot-selling sizes, and available sizes for your reference.

| SBR Rubber Sheet | Thickness(mm) | Width(m) | Length(m) |

| Popular Size | 0.8-1.5mm 2-10mm | 1-1.5m | 10-20m |

| Available Size | 0.4-50mm | 0.2-3m | Any/Customized |

| Ultra Thin | 0.4-1mm | 1-1.2m | Any/Customized |

| Extra Wide | 2-10mm | 2-3m | 10m |

All SBR rubber sheets are strictly implemented: full-size tolerance control following international standards.

Excellent Physical Properties Of SBR Rubber Sheet

- Wear resistance: SBR rubber sheet has excellent wear resistance, second only to BR rubber, and is suitable for applications requiring high wear resistance.

- Aging resistance: SBR rubber sheet has good anti-aging performance, can adapt to various natural environments, and extend service life.

- Good elasticity: In addition, SBR rubber sheet also has good adhesion, crack resistance and certain solvent resistance, suitable for a variety of industrial application scenarios.

Application Scenarios Of SBR Rubber Sheets

If you want to find the most widely used rubber sheet that can be used in all general occasions, then SBR rubber sheet is definitely the best choice. (Except for special properties such as oil resistance, heat resistance, and special media resistance)

- Automobile manufacturing: SBR rubber sheets are widely used in automobile manufacturing and can be used to make tires, sealing strips, fenders, etc.

- Electronic appliances: SBR rubber sheets are used to make insulating gaskets, etc. due to their good conductivity, insulation, wear resistance and anti-aging properties

- Aerospace: SBR rubber sheets are also important in the aerospace field. Their anti-oxidation, anti-ultraviolet and anti-radiation properties enable them to operate stably in extreme environments

- Construction engineering: SBR rubber sheets can be used for insulation, waterproofing, fire prevention and sound insulation in construction engineering, such as making roof waterproofing, basement waterproofing, aerated concrete sound insulation, etc.

- Industrial applications: SBR rubber sheets are also widely used in various industrial fields. Its durability, versatility and easy installation and maintenance make it perform well in these environments.

Advantages of SBR Rubber Sheet

- Excellent processing performance: SBR is easy to install and customize, suitable for various industrial applications.

- Cost-effectiveness: Compared with natural rubber, SBR rubber sheet is more cost-effective, can provide higher cost-effectiveness, and save costs.

- Excellent physical properties: SBR rubber sheet has physical properties such as wear resistance.

Comparison of Rubber Temperature Resistant Ranges

This table clearly compares the temperature resistance range of various rubber sheet materials (such as Silicone, NBR, EPDM, FKM, etc.), helping you quickly understand the applicable temperature environment of different materials. Through intuitive data comparison, it can provide professional reference for your product material selection and ensure that excellent performance is maintained under high or low temperature conditions.

Different Rubber Sheet Materials: SBR, CR, EPDM, NBR, FKM, NR, Silicone, CSM, IIR, FVMQ, HNBR

The data is based on ASTM standard testing and is authentic and reliable.

However, in special cases, different formulas can be added to meet your more specific practical application scenarios. Please contact AOBO, and our engineers can provide more detailed material selection suggestions.

Chemical Adaptability of Various Rubber Materials

The chemical compatibility comparison table of AOBO’s rubber sheet materials is as follows: clearly showing the key performance indicators of acid resistance, alkali resistance, oil resistance, etc. of each category (such as NBR, EPDM, FKM, etc.), helping you quickly select the material solution that best matches the working conditions.

Different Rubber Sheet Materials: CR, SBR, EPDM, NBR, IIR, Hypalon, VMQ, HNBR, FKM, FFKM, FVMQ, FEPM, Silicone

Different Chemical Adaptability: Resistant to Acids, Oils, Steam, Ethers, Alcohols, Alkali, Ketones, Amines, Aldehydes.

Divided into 4 Grades: Excellent, Good, Fair, Poor

All data are verified by ASTM standard tests, providing a scientific basis for material selection for your equipment sealing and pipeline applications.

The above parameters are for reference only. Due to the different acids (such as dilute sulfuric acid, hydrochloric acid, acetic acid, etc.), alkalis, oils, and their concentration differences may have different effects on various rubber products. Please confirm with the AOBO technical department for specific tolerance performance.

SBR Rubber Sheet Packaging

AOBO offers different packaging ways for SBR Rubber Sheet, you can choose or we can suggest to you.

Packaging According to Your Requirement.

SBR is one of the earliest synthetic rubber materials, made by polymerizing styrene and butadiene in a ratio of approximately 3:1.

We can provide you with a variety of colors

SBR rubber sheet has good waterproof performance and is suitable for occasions that require waterproofing.

Related Hot Sell Rubber Sheets

Ultra-wide temperature range (-60℃~230℃), excellent weather resistance, and insulation.

CR has outstanding performance in ozone resistance, weather resistance and flame resistance.

High-quality, versatile, and high-performance rubber sheet material that is widely recognized.