AOBO Skirtboard Rubber Performance

- AOBO skirtboard rubber extends the life of mining equipment by 30%

- Width: 2cm to 80cm

- Tensile Strength: 3-24 MPa

- Material: SBR, NBR, EPDM, CR, natural rubber, sandwich rubber sheet, etc.

- Use professional cutting equipment to ensure smooth edges without burrs.

- Free samples available

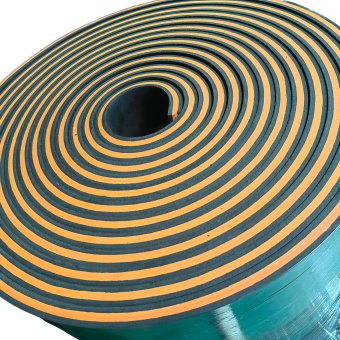

Wear-Resistant NR Orange Skirting Rubber for Mining

Orange Skirtboard rubber made from top quality in 40/45 Shore A Natural Rubber, this is a proven and recognized reliable solution from the mining industry.

1. Color: Orange and Yellow. High visibility for quick wear detection and early maintenance.

2. Material: Natural Rubber. Elastic, tear-resistant, impact-resistant, and resilient. It better absorbs the impact energy of large ore chunks and conforms tightly to the belt.

3. Hardness: 40/45 Shore A, Soft. A perfect balance of flexibility (for optimal sealing) and rigidity (for abrasion resistance), representing the ideal combination of service life and sealing performance.

AOBO Skirtboard Rubber

Skirtboard Rubber Sheeting is cut into strips or blocks by strip cutting machine according to your specific need. AOBO skirtboard rubber is made from durable rubber compounds, they are flexible, resist wear and tear, providing a protector for your equipment, or effective barrier against material spillage and dust emission from conveyor belts.

If you need skirtboard rubber to fill the gaps between equipment or adapting to conveyor contours, then AOBO New Material company will definitely be your first choice. We can provide you with the skirtboard rubber strips of various sizes you need, ensuring a perfect fit for your specific requirements. AOBO with 20years production experience, so efficient production and logistics, can guarantee fast and reliable delivery to meet your project timelines.

Popular Skirting Rubber Colors

Color is not just about aesthetics; it’s also an extension of functionality and safety.

AOBO offer 8 of the most popular colors for skirt rubber sheet to meet your diverse application needs.

Colors can be customized with different color combinations.

Popular Types Skirtboard Rubber Specifications

With 20 years of professional experience in the rubber field, AOBO has carefully selected a series of high-performance skirt board rubbers that are widely recognized in the market, covering different materials such as SBR, NBR, EPDM, etc.

Each skirtboard rubber is marked with key performance parameters (such as tensile strength, hardness, material content, etc.). These types really sell hot in the world market, to help you select more conveniently.

We also support a full range of customized services. If you want to change the material, strength, hardness, and other properties, please contact AOBO for specific details.

Custom Skirting Rubber Strips | Sandwich, Beveled & CN Layer Solutions

Precision-Cut Skirting Rubber Strips

Your conveyor systems demand more than just a basic strip. That’s why we offer precision-engineered skirting rubber strips, designed to solve specific industrial challenges.

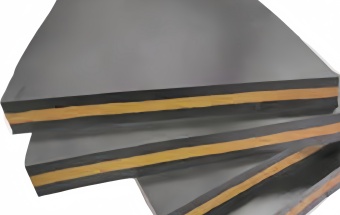

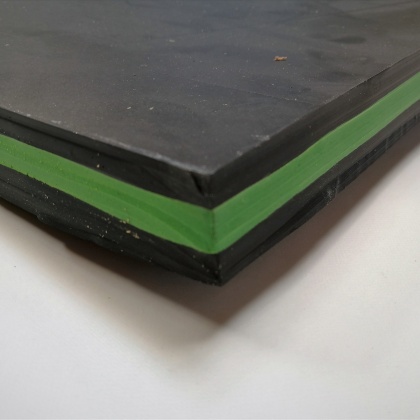

Maximize Lifespan with Our Multi-Layer Composite Skirting Rubber

Maximize Lifespan with Our Multi-Layer Composite Skirting Rubbera hard-wearing top layer to resist abrasion, a shock-absorbing middle core to dampen impact, and a flexible base combined together.

Achieve Zero-Leakage with Our Precision Beveled (45°/35°) Skirting

Achieve Zero-Leakage with Our Precision Beveled (45°/35°) SkirtingAOBO precision-beveled skirting rubber features a custom-cut 45° or 35° angle on the contact edge, allowing it to conform flawlessly to the contour of your conveyor belt.

Easy to Install with CN Layer Skirting Rubber

Easy to Install with CN Layer Skirting RubberDurable and long-lasting: The CN layer is firmly bonded to the rubber matrix, ensuring long-lasting and effective anti-stick properties.

Skirtboard Rubber Classification by Functional

Standard Black Skirting Rubber

Standard Black Skirting RubberCost-effective, Suitable for most common working conditions.

High-Impact Skirting Rubber

High-Impact Skirting RubberHigh-Rebound NR Material maintains excellent seal after impact.

FARS Skirting Rubber

FARS Skirting RubberFARS (Fire Antistatic) Meets FARS standards, flame retardant and antistatic.

Oil Resistant Skirting Rubber

Oil Resistant Skirting RubberNBR material special formula for excellent oil resistance.

AOBO Skirtboard Rubber Available Size

AOBO provides comprehensive skirtboard rubber size and customization services for size, covering the hot-selling sizes, and available sizes for your reference.

| Thickness | Width | Length | |

| Popular Size | 2-30mm | 10-50cm | 10-20m |

| Available Size | 1-50mm | 2-80cm | 1-30m |

Advantages of AOBO Skirtboard Rubber

AOBO Advantage–Customized services:

1. Flexible customization: You can choose materials, sizes, and specifications to accurately match project requirements

2. Professional packaging: Make sure transportation safety

3. Quality commitment: More competitive factory price while promising good quality

4. Good After-sales

Skirtboard Rubber Product advantages:

• Precision cutting technology ensures smooth edges

• Durability and flexibility, easy and efficient installation

• Different material combinations to meet different working conditions

Excellent Durability of Skirtboard Rubber

AOBO New Materials’ skirt board rubber is carefully crafted for superior performance.

Made from high-quality compounds, AOBO Skirtboard rubber in highly flexible, and exhibit excellent impact and chemical resistance. Resistant to cuts, abrasions, and deformation. It maintains integrity for a long time in harsh environments, greatly reducing the frequency of replacement.

At the same time, its excellent shock absorption performance, with a unique formula to cushion vibrations and reduce shock transmission, helps extend service life. In addition, it is resistant to all kinds of weather, including UV rays, moisture, and temperature fluctuations, ensuring that you can operate reliably in any climate conditions.

Skirtboard Rubber Flexible Applications

AOBO Skirtboard rubber is a versatile material designed for applications such as protective barriers.

AOBO skirt board rubber is designed with superior flexibility in mind, easily conforming to a variety of surfaces and shapes. This adaptability allows it to be seamlessly integrated into a variety of applications, providing optimal fit and efficiency even in complex installations and dynamic environments.

- Protect all equipment, especially in mining

- Fill in the gap between your equipment and its own protective rubber

- Adapting to conveyor contours and conveyor belt sidewalls

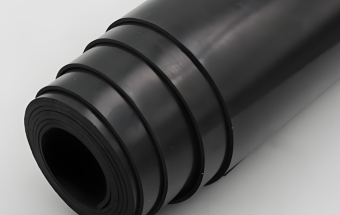

AOBO Skirtboard Rubber Packaging

AOBO offers different packaging ways for skirtboard rubber, you can choose or we can suggest to you.

Packaging According to Your Requirement.

No, its elastomeric composition is designed to be low maintenance. Routine cleaning is usually sufficient to maintain its appearance and functionality, helping to reduce maintenance time and financial investment.

Yes. AOBO New Material company’s skirtboard rubber is designed for easy installation, ensuring a smooth and efficient application process. This AOBO skirtboard rubber is lightweight and flexible, allowing it to be easily cut, installed and fastened to a variety of surfaces.

This user – friendly product reduces labor time and installation costs, providing reliable performance and a perfect finish for any project.

It is very important to choose the right tool to ensure the accuracy and efficiency of cutting. AOBO recommends the following common cutting tools and their applicable scenarios for your reference:

- Rubber cutting knife or utility knife: This tool is specially designed for cutting rubber materials, with a sharp blade and moderate hardness, especially suitable for thinner rubber sheets.

- Electric cutting machine: Suitable for cutting thicker rubber sheets. Electric cutting machines with sharp blades and vacuum cleaners can reduce dust generated during cutting.

- Vibrating knife cutting machine: It can ensure smooth and precise cutting edges. It is suitable for processing rubber sheets with a thickness of no more than 30 mm, and can automatically load and unload materials to improve work efficiency.

- Laser cutting machine: It has the best cutting effect and is suitable for cutting scenarios with large quantities and high precision requirements.

Related Hot Sell Mining Rubber

Diamond pattern, excellent anti-slip and wear resistance, with CN-layer.

High elasticity and wear resistance, made of NR/SBR. 10MPa 15MPa popular.